Conveyor systems, such as belt conveyors and telescopic stackers, are essential for material handling. The efficiency and cost of these systems largely depend on the design and performance of the rollers. Rollers account for 35% of the total cost of a conveyor system and generate over 70% of the resistance. Therefore, the quality of the rollers directly affects the operational efficiency, energy consumption, and service life of the conveyor.

Types of Rollers and Their Functions

- Position: Stainless steel rollers are often used in the conveyor's carrying section. They handle heavy loads and are used frequently.

- Function: Stainless steel rollers are strong, resist corrosion, and have a smooth surface. This helps reduce wear on the conveyor belt and makes it last longer. Because they resist corrosion so well, stainless steel rollers are popular in industries that require high hygiene standards.

- Applications: They are suitable for environments with high humidity or corrosive conditions, such as food processing, chemicals, and pharmaceuticals.

- Function: The main job of a belt training roller is to adjust the conveyor belt's position automatically. This helps the belt run along the right track. This helps prevent belt misalignment, reducing wear and tear on the equipment.

- Applications: Commonly used in large-scale conveyor systems in industries such as mining, logistics centers, and ports.

- Position: The return roller is located in the conveyor's return section, where it supports the belt's return portion, preventing any possible drooping.

- Function: Return rollers keep the belt stable by reducing sagging. This lowers friction between the belt and support rollers. As a result, energy consumption is reduced.

- Applications: Suitable for all types of conveyor systems, especially those with long-distance conveying.

- Position: Carrying rollers are placed under the conveyor belt in the material carrying section.

- Function: Carrying rollers support the weight of the belt and the material. People recognize them for their durability and low rotational resistance, which helps reduce energy consumption in the conveyor system.

- Applications: Used in bulk material handling systems such as coal, ores, grains, etc.

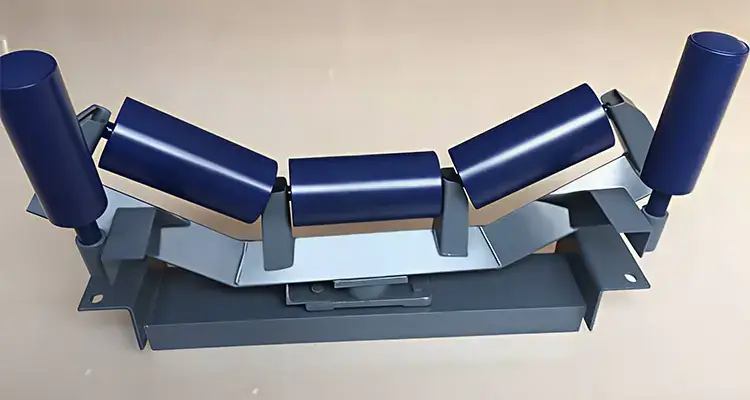

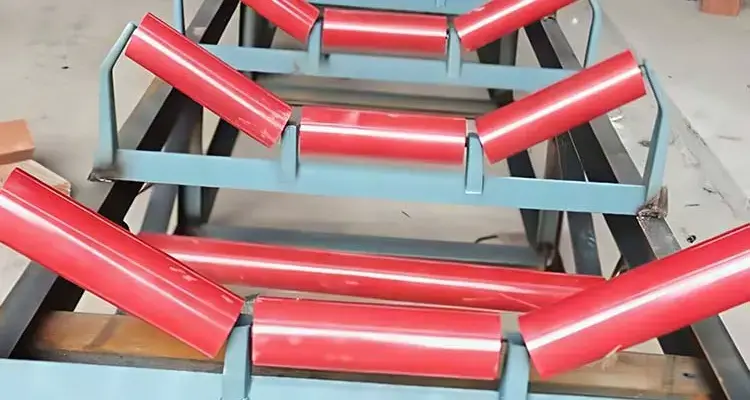

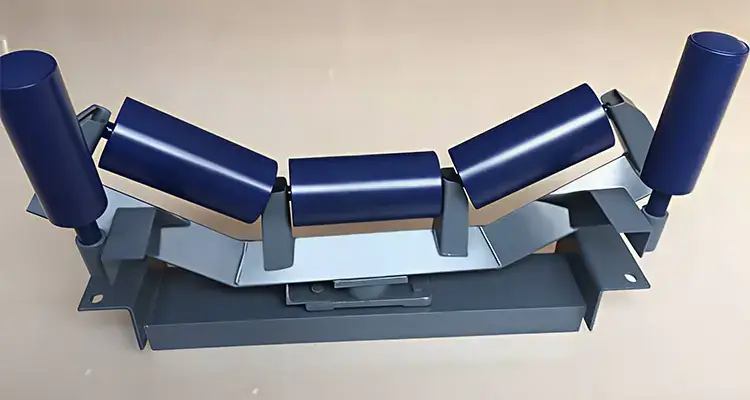

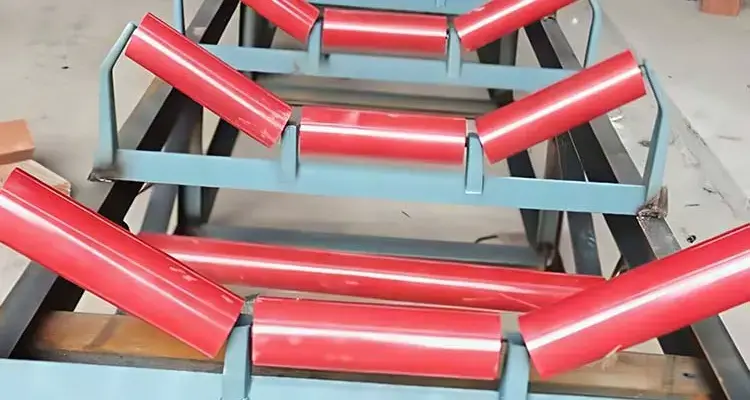

- Function: Troughing rollers are made up of several rollers set in a V-shape or U-shape. They usually have a 30° angle. This design keeps the material stable on the conveyor. It also stops the material from sliding off the belt.

- Applications: Ideal for bulk material handling, especially in environments where material stability is essential.

- Position: Tapered rollers are mainly used in the curved parts of a conveyor. They help reduce friction and allow the conveyor belt to move smoothly.

- Function: Tapered rollers reduce friction. This stops material from slipping as the belt turns. It helps keep goods moving steadily.

- Applications: Suitable for conveyors with many bends, especially in the curved sections.

- Function: Friction conveyor rollers create more friction to stop the conveyor belt from slipping. This helps the material move smoothly along the belt.

- Applications: Ideal for conveyor systems with complex paths or multiple angles, such as automated logistics systems and mining conveyors.

- Function: Rubber disc return rollers have several rubber discs. These discs help reduce dust, oil, and debris on the conveyor belt.

- Applications: Conveyor belts are often used in tough working conditions. These include high temperatures, high humidity, and corrosive environments. This helps to extend the service life of the conveyor belt.

- Function: The unique design of spiral return rollers effectively cleans the conveyor belt, preventing material residue from causing malfunctions.

- Applications: Suitable for high-pollution, high-wear environments, such as mining and sand/stone transportation systems.

- Position: Impact rollers are usually placed where materials hit the conveyor. They provide cushioning to protect the belt from damage.

- Function: Impact rollers absorb shock from material hits. This protects the belt and helps the equipment last longer.

- Function: HDPE (High-Density Polyethylene) rollers are lightweight and highly resistant to corrosion, making them ideal for humid and chemically corrosive environments.

- Applications: Commonly used in environments with high moisture or chemical exposure, such as pulp, paper, and chemical transportation systems.

Please contact us using the info below if you have any questions about what are the various types of rollers used in conveyor belts

How to Choose the Right Roller

Choosing the right roller depends on the material being moved. It also depends on the operating environment, the conveyor belt load, and the working temperature.

- Based on Material Type: Different materials require different roller specifications. For bulk materials, choose heavy-duty, wear-resistant rollers like carrying rollers and troughing rollers.

- Considering the Operating Environment: Harsh conditions like high heat, humidity, and corrosion need special rollers. Use corrosion-resistant options like stainless steel rollers and HDPE rollers.

- Durability and Maintenance Needs: High-frequency use requires rollers with excellent durability to minimize maintenance costs.

- Choosing a Reliable Manufacturer: Picking an experienced and trustworthy manufacturer guarantees the quality of the rollers. This helps ensure the equipment runs smoothly for a long time.

Choosing Zoomry

Zoomry Heavy Industry Co., Ltd. is a top maker of conveyor equipment. They offer many high-quality rollers for different customers. With advanced technology and strict quality checks, Zoomry makes sure every roller works well and lasts a long time.

- High-quality materials and advanced manufacturing processes: Whether steel or plastic rollers, Zoomry uses premium materials and precise processing techniques to ensure high precision and durability of the products.

- Strict quality inspection: Each product undergoes thorough quality checks during production to ensure it is free from cracks and defects, extending the service life of the rollers.

- Efficient supply chain management: Zoomry has strong production capabilities and an effective supply chain. This allows them to quickly meet customer needs and ensure timely delivery.

- Complete technical support and after-sales service: Zoomry stays in close touch with customers. We help with product customization, installation guidance, and ongoing support. This ensures the equipment remains stable over time.