The impact rollers produced by Zoomry Heavy Industry are specifically designed to alleviate the impact at material loading points, reducing damage to conveyor belts. Belt conveyors often handle large volumes of materials, especially during hopper unloading, where sudden impacts can cause serious damage to the conveyor belt. To effectively protect the belt and its components, Zoomry’s impact rollers are designed with high-quality materials to withstand high-impact forces, prolonging the lifespan of the conveyor system and enhancing its stability and efficiency.

Impact rollers are typically installed at material loading areas, acting as the first line of defense for the conveyor belt. By absorbing and dissipating the impact forces generated when materials drop, these rollers effectively prevent excessive wear and tear or belt rupture. Zoomry’s design ensures that impact rollers provide efficient impact absorption and long-term reliability, especially in environments where bulk, blocky, or fragile materials are handled.

■ Application Scenarios

Impact rollers have a wide range of applications in high-intensity industrial environments, particularly in coal washing plants, coking plants, chemical factories, mines, power plants, and more. They are primarily used in material loading points to ensure that the conveyor belt is not subjected to excessive impacts, thus reducing the burden on the belt. Impact rollers are especially useful in handling large or heavy materials, helping to reduce wear and tear and protect the conveyor belt and other key components.

In environments such as coal washing plants and coking plants, where corrosion is a concern, the corrosion resistance of the impact rollers is especially important. Zoomry’s impact rollers are made of high-quality corrosion-resistant materials, ensuring a long service life even in harsh conditions and reducing maintenance frequency.

■ Product Features

● High Impact Absorption: Zoomry’s impact rollers are designed to absorb the maximum impact force when materials land. Their advanced rubber ring structure effectively disperses and mitigates the impact, protecting the conveyor belt from damage.

● Durability: Constructed with high-strength steel and special treatment processes, the rollers can withstand high-impact forces from heavy materials and maintain stable performance even in harsh environments, reducing the maintenance requirements of the conveyor system.

● Corrosion Resistance: These rollers are ideal for corrosive environments, as they effectively resist acid, alkali, and other chemical substances, extending service life and ensuring stable long-term operation.

● Multiple Types Available: To meet various conveyor needs, Zoomry offers different types of impact rollers, including trough-shaped, flat, eccentric trough-shaped, and ringed impact rollers. These designs provide optimal solutions for different working environments and material handling needs.

● Easy Installation and Maintenance: The design of Zoomry’s impact rollers ensures ease of installation and long maintenance intervals. High-quality seals reduce the ingress of dust and moisture, lowering the frequency of maintenance.

● Strong Adaptability: Whether in high-temperature, high-humidity, or dusty environments, Zoomry’s impact rollers maintain excellent performance and adaptability, ensuring the conveyor system runs smoothly in various harsh conditions.

■ Product Types

● Trough-Shaped Impact Roller Assembly

This type of impact roller is designed with a traditional trough shape to effectively absorb large impacts. It is widely used in material unloading areas and is commonly applied in heavy-duty operations in coal mines and power plants.

● Flat Impact Roller Assembly

The flat impact roller features a simple and sturdy design, capable of handling lighter impact loads. It is ideal for conveying light to medium-weight materials and offers a high cost-performance ratio.

● Eccentric Trough-Shaped Impact Roller Assembly

The eccentric design of this impact roller provides a more even distribution of impact forces. It is suitable for delicate material handling applications where fine control of impact absorption is required.

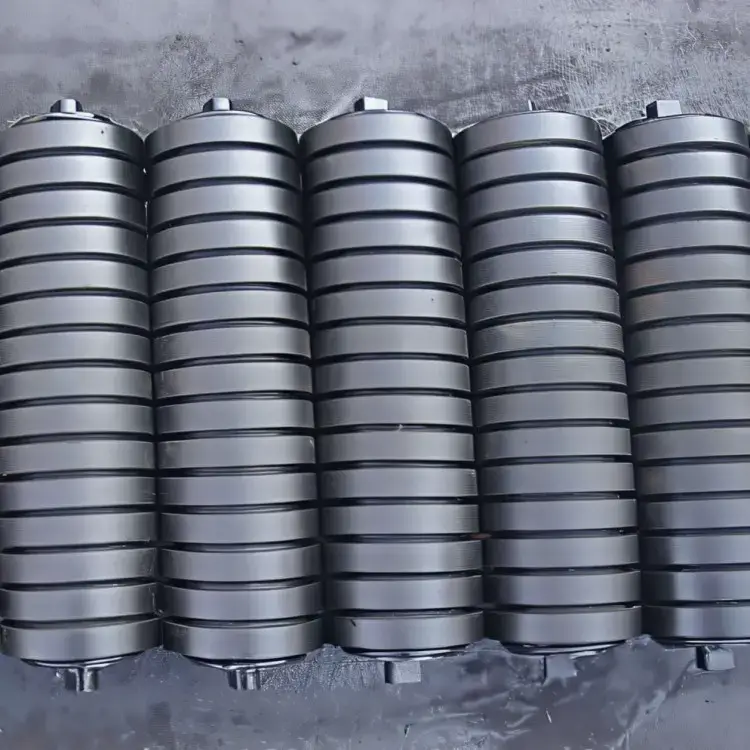

● Ringed Impact Roller Assembly

Featuring multi-layer rubber rings, this type of impact roller provides superior impact absorption and extended service life. It is particularly suited for handling heavy and large materials.

■ Product Parameters

● Roller Diameter: Customizable based on customer requirements

● Rubber Ring Material: High-strength synthetic rubber, wear-resistant and corrosion-resistant

● Bearing Type: High-quality sealed ball bearings, maintenance-free design

● Operating Temperature Range: Suitable for high-temperature environments

● Belt Width Compatibility: Customizable to accommodate different conveyor belt sizes

● Service Life: Typically 3-5 years, depending on environmental conditions and usage

| Name | Belt Conveyor Impact Roller |

| Standard | DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc. |

| Shaft Diameter | 15, 20, 25, 30, 40, 45, 50mm |

| Roller Shell Thickness | 3, 4, 6mm |

| Roller Shell Diameter | 60, 63, 89, 108, 133mm |

| Roller Diameter | 89, 108,133, 159, 180, 194, 215mm |

| Roller Length | 190-1600mm |

| Bearing No. | 6202, 6204, 6205, 6305, 6206, 6306, 6308 |

| Color | Customized |