Zoomry Heavy Industry manufactures Belt Conveyor Self-aligning Training Roller Assemblies, which are widely used for tracking and correcting belt misalignment on both the return and carrying sides of the conveyor belt. These rollers are especially suitable for reversible conveyors, high-load systems, and slow-moving conveyors. The self-aligning function automatically adjusts the roller angle, ensuring the conveyor belt stays on the correct path. This helps prevent misalignment, extends the belt's lifespan, and improves the overall stability of the conveyor system.

■ Application

Belt Conveyor Self-aligning Training Rollers are widely used in both the return and carrying sections of conveyor belts, particularly in high-load or bi-directional systems. The self-aligning rollers adjust automatically to the changes in the load or operational conditions, ensuring the belt stays aligned. They are ideal for use in mining, steel mills, power plants, cement plants, and other heavy-duty industries. In coal mines, power plants, and other environments with heavy loads or complex conditions, these rollers not only improve transportation efficiency but also reduce equipment damage and maintenance costs caused by belt misalignment.

In high-load, bi-directional, and slow-moving environments, self-aligning rollers help maintain the correct path of the conveyor belt, preventing operational interruptions caused by misalignment. For industries such as coal mining and thermal power plants, which require heavy-duty conveyor belts, these rollers offer excellent adjustment capabilities and durability, ensuring stable operation in harsh environments.

■ Features

● Self-aligning Function: The self-aligning rollers automatically adjust the roller angle to keep the belt aligned, preventing misalignment.

● High Load Capacity: Made from high-strength materials, Zoomry self-aligning rollers are designed to carry heavy loads, making them suitable for transporting bulk materials.

● High Temperature and Corrosion Resistance: The rollers are designed to withstand high temperatures and corrosion, making them ideal for environments like coal mines and power plants.

● Reduced Friction: The smooth surface of the rollers reduces friction between the conveyor belt and the rollers, enhancing transport efficiency and reducing energy consumption.

● Long Service Life and Low Maintenance: Optimized design ensures long service life and reduced maintenance frequency and costs.

● Multiple Types Available: Zoomry offers a range of self-aligning roller assemblies, including troughed self-aligning rollers, friction self-aligning rollers, and tapered self-aligning rollers, to meet various conveyor needs.

■ Product Types

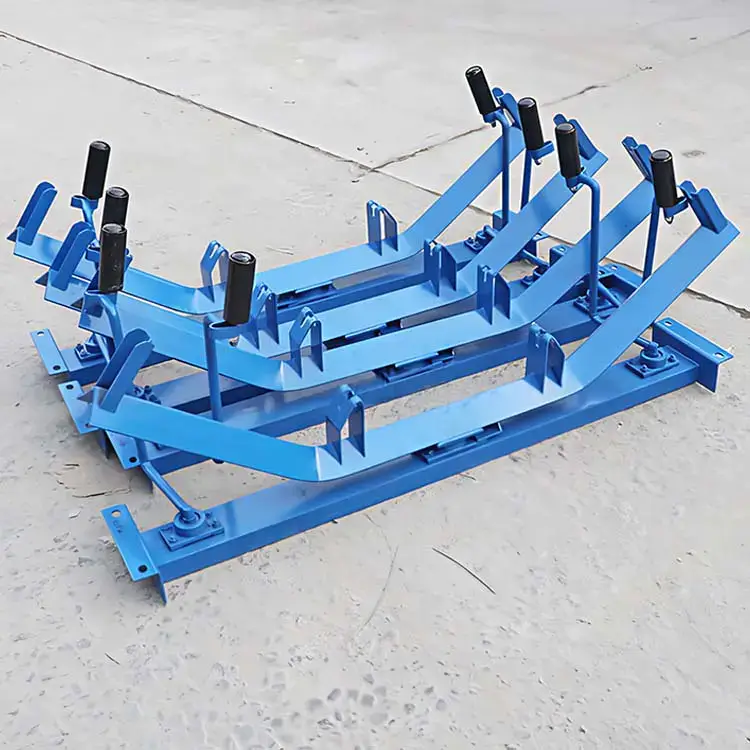

● Troughed Self-aligning Roller Assembly

This assembly consists of three rollers and two guide rollers, suitable for high-load or precision-adjustment conveyor systems. It effectively prevents belt misalignment caused by uneven loads, ensuring stable operation of the system.

● Friction Self-aligning Roller Assembly

Composed of two friction rollers and one steel roller, this assembly is ideal for more complex conveyor systems and uses friction to guide the return belt.

● Tapered Self-aligning Roller Assembly

This type consists of two tapered rollers and one or two standard rollers, designed to offer powerful adjustment capabilities, adapting to various conveyor belt environments.

● Return Self-aligning Roller Assembly

This return roller assembly consists of one or two standard rollers and two guide rollers, primarily used in the return section of the conveyor belt to prevent misalignment during the return process.

■ Product Parameters

| Specification of Conveyor Training Rollers |

| Training Roller Type | Belt Width (mm) |

| Self-aling Trough Roller (3 rollers) | 400 - 2200 |

| Trough Friction Idler, Self-aling Roller (3 rollers) | 400 - 1400 |

| Trough Tapered Idler, Self-aling Roller (3 rollers) | 800 - 2000 |

| Return Training Roller (1 roller) | 400 - 1600 |

| Return Training Roller (2 rollers) | 400 - 2200 |

| Standard | DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc. |