The conveyor impact bed is a device specifically designed for the loading points of conveyor systems. It effectively absorbs the impact force generated when materials fall from a height onto the conveyor belt and the structure. Typically installed at the bottom of the chute, the impact bed provides protection to the conveyor belt through the use of impact bars and a robust support frame. The primary goal of the impact bed is to reduce wear on the conveyor belt, extend the lifespan of the equipment, and improve the overall operational efficiency of the system.

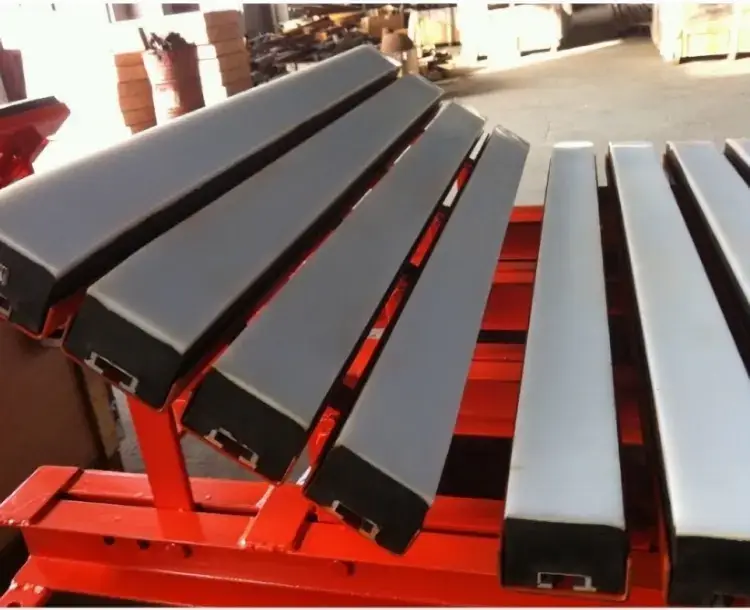

Impact beds are mainly composed of Ultra-High Molecular Weight Polyethylene (UHMW), natural rubber, and an aluminum alloy fastening structure. The core component, the impact bar, offers highly wear-resistant and impact-resistant protection to alleviate the pressure caused by material drop, ensuring that the conveyor belt can operate reliably even in harsh conditions.

Impact beds are widely used in environments where large materials are handled, such as coal mines, ports, steel plants, and cement plants. They are especially suited for conditions with significant material drop impact. Whether handling large ore blocks or highly abrasive bulk materials, the impact bed provides effective protection to the conveyor system, extending equipment life, reducing downtime, and significantly lowering maintenance costs.

■ Components and Working Principle

1. Ultra-High Molecular Weight Polyethylene (UHMW): The surface of the impact bar is made from UHMW material, which has excellent wear resistance and impact strength. It significantly reduces the wear on the conveyor belt during impact. Additionally, UHMW's self-lubricating properties help lower friction, ensuring smooth operation of the conveyor belt.

2. Natural Rubber Layer: The middle layer of the impact bar is made from natural rubber, which offers good elasticity and shock-absorbing capabilities. When materials fall from a height, the rubber layer absorbs and disperses the impact energy, reducing the direct force transmitted to the conveyor belt, thereby preventing surface scratches or cracks.

3. Aluminum Alloy T-Slot: Each impact bar features an aluminum alloy T-slot at the bottom, enabling quick and secure attachment to the impact bed frame. The T-slot not only reinforces structural stability but also makes the installation and removal of the impact bars more convenient, significantly reducing maintenance and replacement time while enhancing operational efficiency.

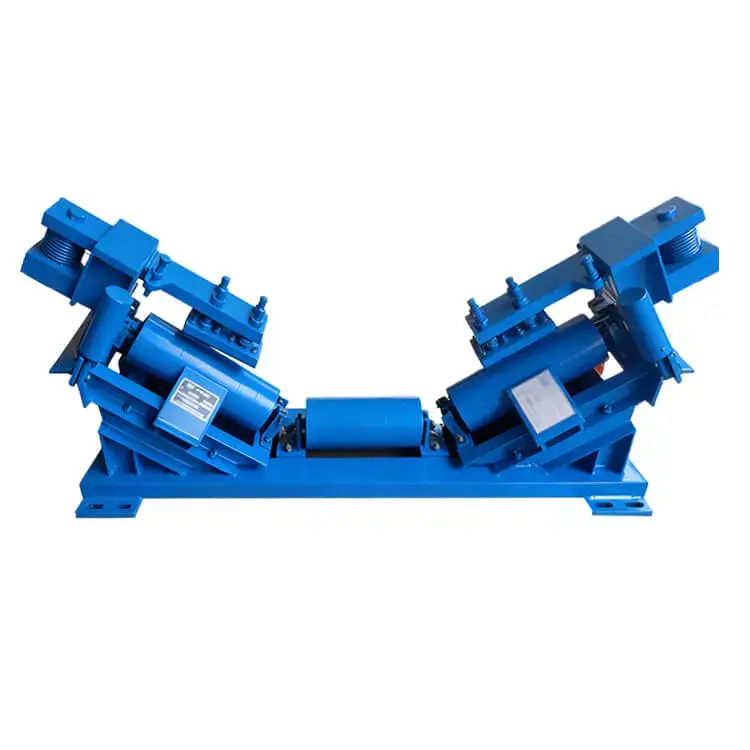

4. Impact Bed Support Frame: The entire impact bed is supported by a robust steel frame, capable of withstanding strong impact forces and ensuring system stability. The frame is typically designed to match the trough angle of the conveyor system and can be customized as fixed-angle or adjustable-angle to meet different operational requirements.

■ Specifications

| Model | Belt width | θ | H(mm) | E(mm) | A(mm) | L1(mm) | Q(mm) | P(mm) | Number of impact bars |

| 200 | 350 | 450 |

| H2 | H2 | H2 |

| B500-L | 500 | 250 | 300 | —— | 180 | 800 | 740 | 225 | 160 | 200 | 6 |

| B650-L | 650 | —— | 329 | —— | 180 | 950 | 890 | 250 | 160 | 200 | 6 |

| B800-L | 800 | 292 | 385 | 389 | 200 | 1150 | 1000 | 276 | 160 | 200 | 7 |

| B1000-L | 1000 | 371 | 462 | 505 | 240 | 1350 | 1200 | 377 | 160 | 200 | 9 |

| B1200-L | 1200 | 388 | 528 | 540 | 257 | 1600 | 1540 | 428 | 160 | 200 | 10 |

| B1400-L | 1400 | 497 | 573 | 680 | 261 | 1800 | 1740 | 479 | 160 | 200 | 12 |

| B1600-L | 1600 | 524 | 655 | 736 | 285 | 2040 | 1980 | 581 | 160 | 200 | 13 |

| B1800-L | 1800 | 578 | 740 | 817 | 310 | 2240 | 2180 | 631 | 160 | 200 | 15 |

| B2000-L | 2000 | 606 | 811 | 874 | 320 | 2480 | 2420 | 740 | 160 | 200 | 16 |

■ Features

1. High Wear Resistance and Impact Resistance: The impact bars, made from UHMW and natural rubber, offer exceptional wear resistance and impact resistance, making them suitable for long-term use in high-intensity work environments, ensuring the conveyor belt's surface remains undamaged.

2. Self-Lubricating and Low Friction Coefficient: The UHMW surface of the impact bars has excellent self-lubricating properties, reducing friction during conveyor belt operation and preventing excessive wear and increased energy consumption caused by high friction.

3. Aluminum Alloy T-Slot Design for Easy Installation and Maintenance: The aluminum alloy T-slot at the bottom of each impact bar ensures quick and secure attachment to the impact bed frame. Installation and removal are convenient, reducing downtime and maintenance costs.

4. Fixed and Adjustable Angle Design: The impact bed can be designed with either fixed or adjustable angles according to different conveyor requirements, ensuring that the system aligns with the conveyor belt's trough angle for optimal operational efficiency.

5. Corrosion Resistance and Long Service Life: The UHMW surface of the impact bars is not only wear-resistant but also corrosion-resistant, enabling long-term stable operation in corrosive environments and further extending equipment lifespan.

6. Modular Design for Easy Maintenance: All components of the impact bed, including rollers, drums, and impact bars, are designed in a modular format, allowing for quick replacement, reducing maintenance difficulty, and improving overall operational efficiency.

7. Reduces Material Spillage and Belt Damage: By absorbing the impact forces of falling materials, the impact bed prevents direct material strikes on the conveyor belt surface, effectively reducing spillage and belt damage.

■ Protection Mechanism

When materials fall from a height onto the conveyor belt at the chute, the significant impact force applied to the belt surface can easily cause damage or tearing. The impact bed, with its UHMW and rubber layers, absorbs and disperses these forces, reducing the direct impact on the belt. The wear resistance and low friction properties of the UHMW ensure that the belt remains intact even after prolonged use, while the rubber layer provides cushioning to minimize wear on the belt surface. This design not only extends the lifespan of the conveyor belt but also reduces maintenance costs for the entire system.

■ Information to Provide Our Engineers

● Conveyor Data:

- Belt width (inches)

- Belt speed (FPM)

- Impact bed length (e.g., 300mm)

- Material type and maximum lump size

- Material density (lbs/ft³ or tons/m³)

- Trough roller angle and roller diameter

- Material drop height

● Operational Data:

- Conveyor name/tag

- Conveyor capacity (sTPH)

- Elevation (feet)

- Operating hours (days/year)