As core equipment for mining, port, and construction industries, Zoomry's conveyor telescopic achieves engineering limits through modular design and intelligent control technology, delivering 20-meter stacking precision and 85-ton/hour processing capacity to redefine bulk material handling standards.

Application Scenarios

| Industry Scenario | Pain Points | Zoomry Conveyor Telescopic | Customer Value |

|---|

| Mining & Quarrying | Open-air material weathering/pollution | Fully enclosed belt system with 75° climbing capacity (-30°C to 50°C adaptability) | Ore moisture control <3% (ISO 13315) |

| Port Operations | Vessel demurrage costs >\$15,000/hour | Rapid mode switching (15-minute barge-truck conversion) | Loading efficiency ↑40% |

| Construction Waste | 50MPa concrete debris equipment damage | Manganese steel scraper + dual-chain drive (>8kN/m² impact resistance) | Equipment lifespan extended to 10 years (Industry average: 6 years) |

| Grain Storage | >2% grain breakage losses | Low-speed gentle conveying (0.5m/s) + FDA-compliant TPU belt | Breakage rate reduced to 0.3% |

| Chemical Materials | Corrosive material structural damage | 316L stainless steel frame + EPDM sealing (pH 1\~14 resistance) | Maintenance cost reduction \$0.8/ton |

Ultra-Efficient Stacking System

- Dynamic amplitude modulation: Conveyor telescopic boom with a telescoping speed of 0.3\~1.2m/s and stepless adjustment adapts to materials with 25°\~50° angles of repose, achieving a 20m stacking height and a 45% improvement in yard utilization.

- Intelligent stacking algorithm: LiDAR real-time modeling generates optimal stacking trajectories (±10cm precision), preventing material segregation.

All-Terrain Mobility

- Hybrid mobility system: Conveyor telescopic combines hydraulic outriggers and heavy-duty tires (<80kPa ground pressure) for marsh/gravel terrain with ≤15° slopes.

- Rapid redeployment: Folded dimensions 12m×3.2m enable standard container transport, improving cross-site transfer efficiency by 70%.

Lifecycle Cost Advantage

- Energy efficiency: Conveyor telescopic advanced power systems reduce energy consumption by 35% vs conventional equipment.

- Maintenance optimization: Modular quick-disassembly design cuts routine maintenance time by 60%, extending critical component lifespan to 50,000 hours.

Comprehensive Safety System

- Triple protection:

- ±0.1° tilt monitoring

- Auto-lock at wind speeds >15m/s

- 30m millimeter-wave obstacle detection

- ISO 13849 PLd compliance with 100,000h MTBF certification.

Multi-Scenario Adaptability

- Material versatility: Handles 1.5\~2.5t/m³ density materials from aggregates to cement with >12kN/m² impact-resistant belts.

- Extreme environment operation: -30°C lubrication and ISO 12944 C5-M anti-corrosion structure ensure reliability in high-humidity/salt-spray environments.

Sustainable Engineering

- Conveyor telescopic achieves >85% recyclability with <75dB(A) noise emission (ISO 4871), aligning with green mining and carbon neutrality requirements.

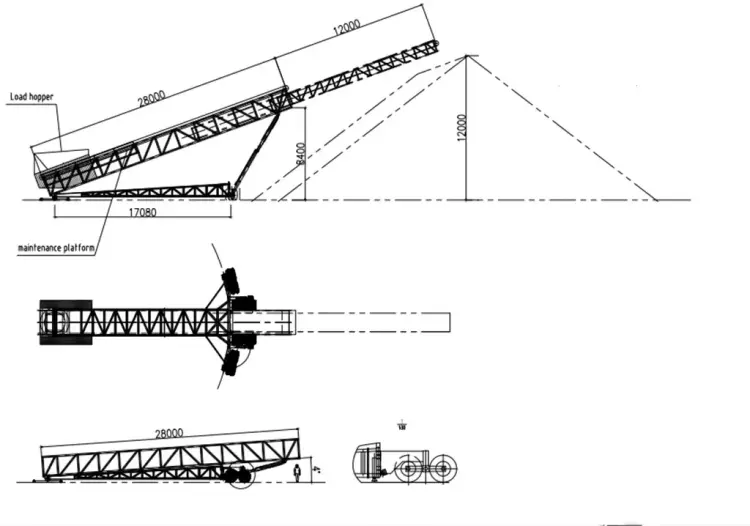

Structural Composition

The conveyor telescopic comprises:

- Hydraulic lifting system

- Front wheel traveling device

- Hydraulic outriggers

- Hydraulic power unit

- Base frame

- Electrical control cabinet

- Tail pulley rotation device

- Tow bar

- Maintenance platform

- Hopper

- Main conveyor belt

- Wire rope traction device

- Telescopic conveyor belt

Ensuring holistic performance and reliability.

Technical Specifications

| Product Name | Conveyor Telescopic |

|---|

| Material | High-quality carbon steel |

| Belt Width | 800mm;914mm(36'');1000mm;1200mm;1400mm;1600mm(Customizable) |

| Capacity | 450-3500m³/h(Customizable) |

| Certifications | ISO9001; CE; ISO14001; EAC; KCS |

| Advantages | Portable; Rotatable; Adjustable inclination; Telescopic length; Radial movement |

| Applications | Mining; Ports; Cement; Steel; Metallurgy; Power; Coal; Machinery |

| Model | Belt Width(mm) | Max Capacity(m³/h) | Belt Speed(m/s) | Std.Length(m) | Max Inclination(°) | Stacking Height(m) |

|---|

| ZR80SF | 800 | 500 | 2.5 | 30/40/50 | 20 | 10-20 |

| ZR100SF | 1000 | 850 | 2.5 | 30/40/50 | 20 | 10-20 |

| ZR120SF | 1200 | 1500 | 3.15 | 30/40/50 | 20 | 10-20 |

| ZR140SF | 1400 | 2100 | 3.15 | 30/40/50 | 20 | 10-20 |

| ZR160SF | 1600 | 3500 | 4.00 | 30/40/50 | 20 | 10-20 |

Why Choose Zoomry?

- Material Science Breakthrough Critical conveyor telescopic components exceed 50,000h service life (ISO 12100 fatigue certification).

- Modular Design Philosophy On-site belt replacement completed in 2 hours (vs 8h conventional systems).

- Global Service Network 12 regional service centers (North America/Middle East/Southeast Asia) guarantee 48h spare parts delivery.

- EPC Project Synergy BIM model pre-delivery (LOD 400 precision) + OPC UA protocol standardization.

- Green Manufacturing Commitment Equipment recyclability >85% compliant with EU ELV Directive.