The Zoomry Truck Unloader is a versatile, high-capacity bulk material handling equipment specifically designed for rapid unloading of materials such as sand, coal, and grains. Available in both wheeled and tracked chassis configurations, it features ramps for easy access by dump trucks and can be integrated with the ZRSF series mobile telescopic stackers. Its modular design and intelligent control system seamlessly adapt to modern logistics systems, achieving a maximum single-unit capacity of 1,800 tons/hour, significantly reducing labor costs and boosting operational efficiency. It is the ideal choice for ports, mining sites, and industrial parks.

Core Configurations & Technical Specifications

Equipment Models

| Model | Truck Unloader Type | Belt Width | Capacity | Key Functional Configurations |

|---|

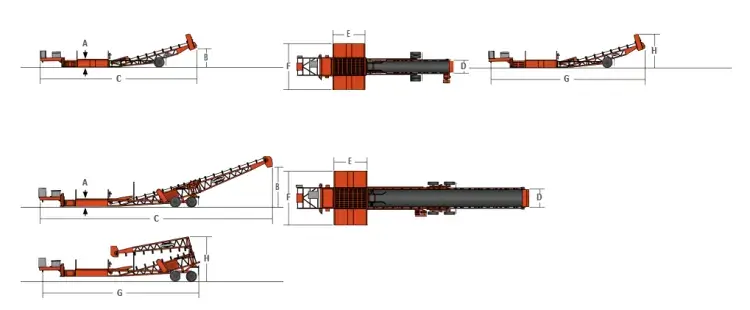

| ZRLS-TU1400 | Wheeled Chassis | 1400 mm | 200-1000 t/h | Remote control, dual/quad-lane ramps, hydraulic/manual adjustment |

| ZRLS-TU1800 | Wheeled Chassis | 1800 mm | 600-1800 t/h | Remote control, dual/quad-lane ramps, hydraulic/manual adjustment |

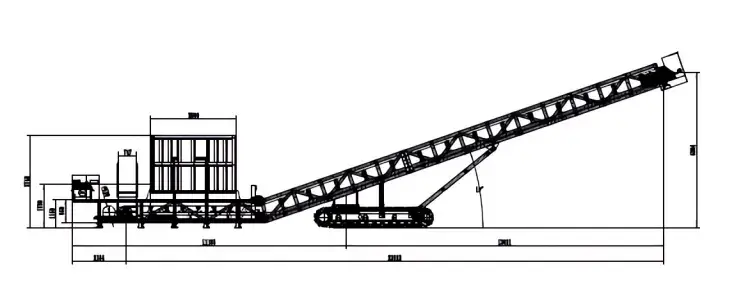

| ZRLD-TU1400 | Tracked Chassis | 1400 mm | 200-1000 t/h | All-terrain adaptability, mining-grade anti-slip design |

| ZRLD-TU1800 | Tracked Chassis | 1800 mm | 600-1800 t/h | Heavy-duty continuous operation, harsh-condition compatibility |

Key Component Design

Heavy-Duty Chassis System

- Wheeled/Tracked Versions: Road transfer speed of 30 km/h (wheeled); stable operation on muddy or sloped terrain (≤15° gradient) (tracked).

- Hydraulic Support Structure: Equipped with pneumatic brakes, indicator lights, and fenders. Maximum unloading height of 6.3 meters, with optional hydraulic lifting jacks.

Low-Profile Receiving Hopper

- Wide Customizable Hopper: Width range 3.5-5.7 meters, compatible with dump trucks, loaders, and excavators. Powered by 5.0-7.5 kW electric/hydraulic units.

- Smart Screening System: Optimized mesh for aggregates and minerals to reduce blockages and material loss.

Conveyor Frame & Drive

- High-Strength Conveyor Belt: EP100 (5+4+2) to EP200 (6+4+3) wear-resistant layers, with on-site vulcanized joints for extended lifespan.

- Dual Drive Head System: Dual 11 kW motors (1800 RPM, TEFC 3/60/460) paired with FLENDER/SEW gear reducers and reverse braking for safety.

- Ceramic-Coated Drums: 20-inch (508mm) drive drum with Haerbin® bearings, belt speed adjustable from 1-4 m/s.

Intelligence & Customization

- Remote Control: Truck unloader supports wireless start/stop and optional Industrial IoT (IIoT) remote monitoring.

- Power Options: 380-460V three-phase power supply or customized onboard diesel generator (for off-grid scenarios).

- Add-Ons: Belt cleaners, discharge covers, hydraulic chassis lifting cylinders, and more.

▲ Modular design ensures easy maintenance, with 60% improved access to critical components

Core Advantages

High-Efficiency Unloading

- Direct integration with dump trucks enables single unloading cycles ≤8 minutes, reducing port vessel berthing time by 50%.

- Tracked truck unloader models (ZRLD series) replace short-haul transport in mines, lowering logistics costs by 30% per ton.

Full-Scenario Adaptability

- Wheeled Truck Unloader: Rapid deployment at ports/warehouses; Tracked Truck Unloader: Stable operation in muddy mines or coastal salt-spray environments.

- High-temperature-resistant belts (300°C) for steel mill sintered ores; ATEX-certified models for hazardous chemical handling.

Extended Lifespan

- High-chromium alloy rollers (150,000-hour lifespan) + IP66-rated bearings reduce failure rates by 40% in harsh conditions.

- Hopper wear liners last up to 6,000 hours, cutting maintenance costs by 50%.

Eco-Smart Operation

- Variable frequency drives save 25% energy; dust suppression systems (<10 mg/m³) meet EU/US environmental standards.

- Precision flow control (<0.5% error rate) ensures zero contamination in grain storage, compliant with FDA/CE certifications.

▲ Simplified unloading process shortens truck cycle times, accelerates material flow, and boosts productivity

Application Scenarios

| Scenario | Solution | Customer Value |

|---|

| Ports | Integrated with mobile shiploaders for automated "unload-stack-load" workflows | Annual demurrage savings exceeding $2 million |

| Mines/Quarries | Tracked truck unloader chassis directly feeds crushers, eliminating 20 short-haul trucks | 30% lower per-ton cost, 3x longer maintenance intervals |

| Grain Silos | Fully enclosed hopper + smart flow control, 5,000 tons daily throughput | 99% dust recovery, <0.3% moisture variance |

| Steel/Chemical Plants | High-temperature/explosion-proof models handle sintered ores and hazardous chemicals | 100% operational safety, <30-second material切换 |

Request a Custom Solution

Zoomry offers free on-site surveys, 3D simulations, and trial services to deliver cost-effective solutions tailored to your site conditions and production needs.