Time:2024-12-17 16:00:03 Number of Clicks:

The discharge end of the shiploader is equipped with a telescopic single-layer steel or double-layer free discharge chute. The end of the discharge chute is equipped with a 360° radial trimmer. The angle of the radial trimmer can be adjusted according to the needs to direct material under coaming areas to ensure that the whole

process is smooth, and the material can be loaded to the corner of the hatch, while reducing dust overflow.

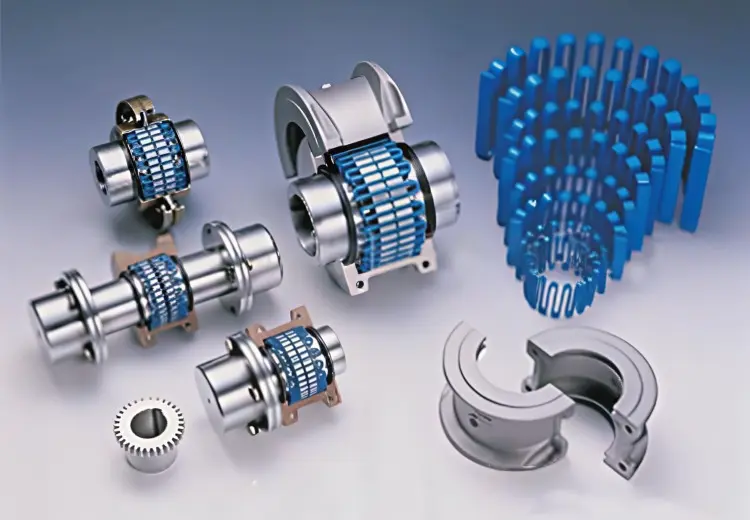

The reducers adopt a fully enclosed reducer with a split self-cooled oil bath welding structure. The gear of the reducer is a hard tooth surface. The hardness of the tooth surface is not less than HRC58. The accuracy of the gear is not be less than level 6. The design and selection of the reducer fully consider the influence of the ambient temperature on the starting and thermal power of the reducer.

The coupling consideration for reducing the form of impact in transmission. The safety factor of the coupling is according to the FEM specification. The coupling are tested for dynamic balance and static balance.

The drive pulleys of shiploader are made of ceramic lagging, and the no-drive drums are made of rubber lagging. The drive drums of the truck unloading feeder come with rubber lagging. Reasonably design the drum structure to ensure structural strength, and at the same time, rationally select the bearing seat. Priority is given to the double-key tight-fit connection between the drum and the shaft; the bearing seat of the redirecting drum adopts the non-tightening sleeve type.

Please contact us using the info below if you have any questions about Zoomry Telescopic conveyor ship loader parts

● https://www.zoomry-ind.com

● +86 136-6401-6717

All bearing housing are reliably sealed to ensure the good storage of grease and effectively prevent dust and rainwater from entering and reduce the service life. The rolling bearings selected by each devices are made of internationally renowned manufacturers, and the theoretical life is not lower than the level of thecorresponding working institution.

All bolts of the complete set of mobile ship loading system are metric and meet ISO standards. Bolts and nuts have anti-loose or anti-falling measures to withstand vibration and change loads. The quality of high-strength friction joint bolts should meet the standard, and the dispersion of pre-tight axial force is required. Bolt nuts need anti-rust measures, and the exposed part should be coated with appropriate coating.

All exposed rotating parts that may cause injury are surrounded by removable protective covers that are easy to inspect.

Copyright © 2002-2024 Zoomry Group Company Limited