The pipe conveyor belt is a specialized conveyor belt designed for pipe conveyors, and its material and style vary depending on the specific usage scenario. Due to the wide range of applications of pipe conveyors, pipe conveyor belts are used in many industries such as coal mining, metallurgy, chemicals, power, and more.

Zoomry Heavy Industry offers high-quality pipe conveyor belts, covering both steel-cord and fabric types to meet the diverse material transport needs across different working environments. Whether in complex transport routes or high-strength and high-stability material handling tasks, Zoomry's pipe conveyor belts provide stable and efficient solutions.

■ Product Introduction

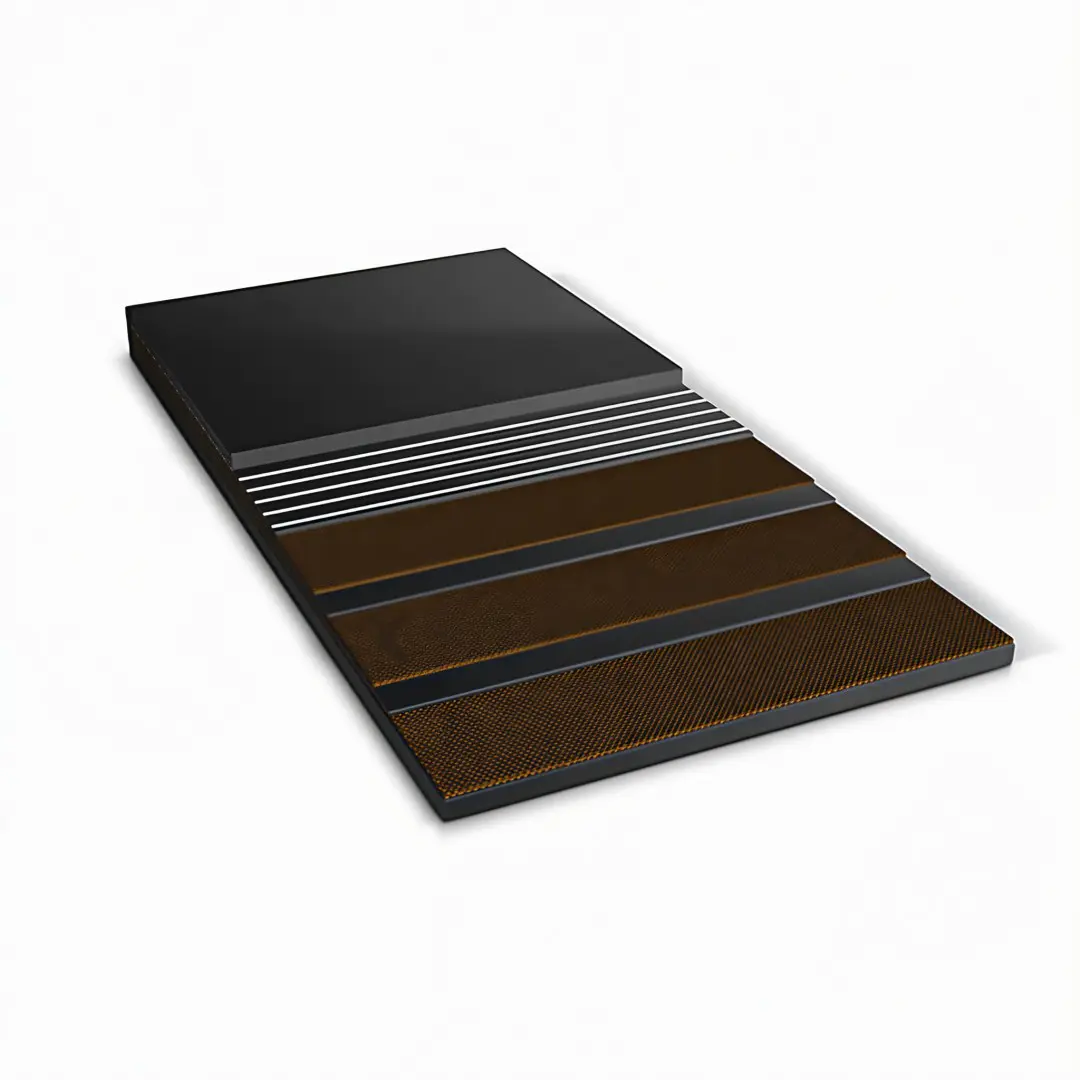

The pipe conveyor belt features a unique design structure that allows material to be transported to its destination at certain angles while forming a tubular structure to prevent material spillage or leakage, offering a more enclosed and secure transportation method. Zoomry's pipe conveyor belts are divided into two main types: steel-cord and fabric types:

● Steel-Cord Pipe Conveyor Belt: This type of conveyor belt uses steel cords as the main framework, offering high load-bearing capacity and excellent tensile strength. It is ideal for environments that require heavy-duty operations, such as coal mining and power generation for large-scale material handling.

● Fabric Pipe Conveyor Belt: This type of conveyor belt uses fabric plies as the framework, offering a lighter and more flexible characteristic compared to steel-cord belts. It is suitable for general load material transport, especially for medium to short-distance conveying.

Zoomry's pipe conveyor belts are made from high-quality rubber materials and advanced manufacturing processes, ensuring long service life and superior performance. With precision engineering, these belts are not only highly durable and wear-resistant but also maintain stable operation in various harsh environments, minimizing downtime caused by belt damage.

■ Application Scenarios

The pipe conveyor belt is widely used across various industries, especially in the following fields:

● Steel and Metallurgical Industry: In steel mills and metallurgy, the pipe conveyor belt can handle high-temperature, high-load material transport. Especially for heavy materials like iron ore and coal, the enclosed structure helps prevent material spillage, improving workplace safety.

● Coal Mining Industry: In coal mines, conveyor belts often face high-frequency and high-intensity work environments, particularly in deep shafts. The closed structure of the pipe conveyor belt effectively reduces the leakage of coal dust, ash, and other materials, preventing environmental pollution and ensuring efficient material handling.

● Power Industry: In power plants, especially for transporting fuel materials like coal, the pipe conveyor belt provides stable conveying services. It is highly resistant to wear and high temperatures, making it suitable for long-term continuous operation in power plants.

● Cement Industry: Cement plants frequently need to handle large amounts of powdery materials. The pipe conveyor belt, with its strong sealing ability, effectively prevents dust leakage, meeting environmental requirements.

● Chemical Industry: Material transport in the chemical industry requires special care to prevent leakage and contamination. The sealed structure of the pipe conveyor belt ensures safe transportation of chemical materials, preventing environmental pollution caused by leakage.

● Paper Industry: In paper mills, pipe conveyor belts are commonly used for transporting pulp, waste paper, and other materials. They are especially useful for conveying in narrow spaces, reducing the dispersion of paper scraps and waste, thus improving factory efficiency.

■ Product Features

Zoomry’s pipe conveyor belts are optimized in both structural design and material selection:

● Strong adaptability, easily forming a tubular structure: The belt’s rigidity is appropriate for easily forming a tubular shape, ensuring material is effectively enclosed, preventing spillage.

● Excellent sealing: The overlap design of the belt ensures tight sealing, preventing material leakage during transportation.

● Fatigue resistance and wear resistance: Using high-strength materials, the pipe conveyor belt offers excellent fatigue resistance, allowing it to efficiently carry materials over extended periods while minimizing frequent replacements due to wear.

● Suitable for curves and steep-angle conveying: These belts are ideal for routes that require large bends or steep angles, ensuring stable material transport without falling.

● Environmental protection: The closed design prevents material spillage, reducing environmental pollution and meeting eco-friendly standards.

● Aging resistance: The belts are made with special rubber compounds, providing excellent oxidation, UV, and aging resistance, ensuring a long service life even in harsh weather conditions.

● Long service life: High-strength steel cords and rubber materials make the pipe conveyor belt durable, maintaining a long usage cycle even in harsh working environments.

■ Product Types

Zoomry’s pipe conveyor belts come in several types to cater to different application needs:

● Steel-Cord Pipe Conveyor Belt: Ideal for high-strength, heavy-duty transport tasks with excellent tensile strength and load-bearing capacity. Suitable for coal mines, steel, and metallurgical industries.

● Fabric Pipe Conveyor Belt: Suitable for general load material transport, lighter and more flexible, ideal for medium to short-distance conveying.

● High-Temperature Pipe Conveyor Belt: Designed for high-temperature environments, suitable for material transport in industries like metallurgy and steel mills, able to withstand high-temperature materials while maintaining efficient operation.

● Corrosion-Resistant Pipe Conveyor Belt: With excellent corrosion resistance, suitable for chemical, mining, and other industries where the belt needs protection from chemical damage.

■ Product Parameters

| Steel Cord Pipe Conveyor Belt |

| Strength Grade | Tensile Strength (KN/m) | Cord Spec(mm) | Cord Min. Break Force (KN) | Cover Min. |

| ST630 | 630 | Cord Pitch=10 | 7 | 4 |

| Cord Diameter=2.8 |

| ST800 | 800 | Cord Pitch=10 | 8.9 | 4 |

| Cord Diameter=3 |

| ST1000 | 1000 | Cord Pitch=12 | 12.9 | 4 |

| Cord Diameter=3.7 |

| ST1250 | 1250 | Cord Pitch=12 | 16.1 | 4 |

| Cord Diameter=4.2 |

| ST1600 | 1600 | Cord Pitch=12 | 20.6 | 4 |

| Cord Diameter=4.7 |

| ST2000 | 2000 | Cord Pitch=12 | 25.6 | 4 |

| Cord Diameter=5.3 |

| ST2500 | 2500 | Cord Pitch=15 | 40 | 5 |

| Cord Diameter=6.8 |

| ST2800 | 2800 | Cord Pitch=15 | 44.8 | 5 |

| Cord Diameter=7 |

| ST3150 | 3150 | Cord Pitch=15 | 50.5 | 5.5 |

| Cord Diameter=7.8 |

| ST3500 | 3500 | Cord Pitch=15 | 56 | 6 |

| Cord Diameter=8.2 |

| ST4000 | 4000 | Cord Pitch=15 | 63.5 | 6.5 |

| Cord Diameter=8.8 |

| ST4500 | 4500 | Cord Pitch=16 | 76.3 | 7 |

| Cord Diameter=9.7 |

| ST5000 | 5000 | Cord Pitch=17 | 91 | 7.5 |

| Cord Diameter=10.9 |

| ST5400 | 5400 | Cord Pitch=17 | 98.2 | 8 |

| Cord Diameter=11.3 |

| Steel Cord Pipe Conveyor Belt |

| Nominal Pipe Diameter(mm) | 200-800 |

| Width | 800-2800 |

| Fabric Cord Pipe Conveyor Belt |

| Strenght (KN/m) | No. of Pipes | Carcass Type | Width |

| 160 | 2 | NN/EP | 300-800 |

| 250 | 2~3 | NN/EP | 400-1000 |

| 315 | 2~4 | NN/EP | 500-1600 |

| 400 | 2~4 | NN/EP | 600-1600 |

| 500 | 2~5 | NN/EP | 750-1600 |

| 630 | 3~6 | NN/EP | 750-2000 |

| 800 | 3~6 | NN/EP | 750-2200 |

| 1000 | 3~6 | NN/EP | 750-2200 |

| 1250 | 3~6 | NN/EP | 900-2200 |

| 1400 | 3~6 | NN/EP | 1000-2200 |

| 1600 | 4~6 | NN/EP | 1050-2200 |

| 2000 | 4~6 | NN/EP | 1050-2400 |

| 2500 | 5~6 | NN/EP | 1200-2400 |

| 3150 | 5~6 | NN/EP | 1400-3000 |

| Fabric Cord Pipe Conveyor Belt |

| Nominal Pipe Diameter(mm) | 150-800 |

| Width | 600-2800 |