Zoomry offers two types of solid woven conveyor belts: PVC and PVG, both featuring exceptional wear resistance, tear resistance, and excellent anti-static properties. These belts are designed for use in harsh environments, including coal mines, power plants, the chemical industry, and other applications that require high strength and wear resistance. Zoomry provides reliable solutions for your conveyor systems with PVC and PVG solid woven belts.

■ Product Introduction

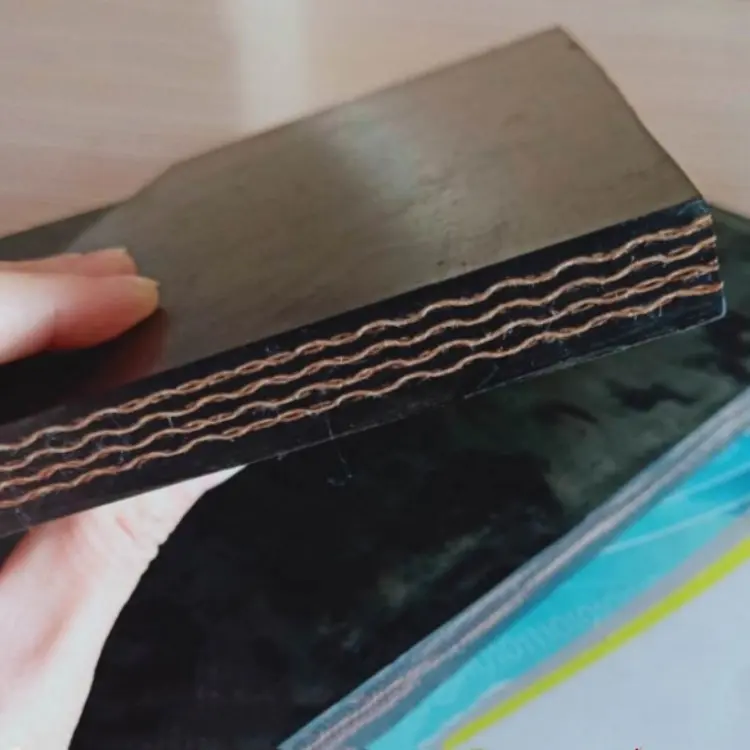

The solid woven conveyor belts provided by Zoomry include PVC and PVG types, both of which offer strong wear resistance, tear resistance, and excellent anti-static properties. These belts are widely used in industries such as coal mining, fertilizers, agriculture, and food, as well as in harsh underground mining environments. They ensure efficient and stable conveyor operations with their durable structure and wear-resistant materials, which help to reduce maintenance needs and prolong service life.

● PVC Type Conveyor Belt:

The PVC type conveyor belt has PVC coatings on both the upper and lower layers, with a coating thickness ≥1.0mm on one side and an angle of inclination less than 16°. It is suitable for coal mines, power plants, chemical, and metallurgical industries, meeting the requirements for high temperature, fire resistance, and anti-static properties.

● PVG Type Conveyor Belt:

The PVG type conveyor belt has upper and lower layers made of nitrile rubber and PVC. It has good thermoplastic elastomer (TPE) characteristics, with a coating thickness between 1mm and 3mm and an inclination angle less than 20°. It is often used for transporting oil products, grain, feed, fertilizers, and agricultural products, offering excellent resistance to material corrosion and abrasion.

■ Application Scenarios

Solid woven conveyor belts have a wide range of applications, particularly in the following industries:

● Coal Mining Industry:

In coal mining, the conveyor belts often have to withstand significant wear and high-temperature conditions. PVC and PVG solid woven conveyor belts can effectively resist coal dust, ensuring the stable operation of the conveyor system and ensuring continuous and efficient material transport.

● Thermal Power Plants:

Thermal power plants often need to transport large amounts of coal and ash. The PVC type conveyor belt can effectively prevent material buildup and slipping, ensuring smooth belt operation.

● Fertilizer and Agricultural Product Transport:

In the transport of fertilizers, agricultural products, and grain, PVG type conveyor belts, with their excellent corrosion and oil resistance, are ideal for handling corrosive materials, ensuring efficient system operation.

● Chemical Industry:

During chemical production, especially in the transport of chemicals and other corrosive materials, PVC and PVG belts' corrosion resistance and acid-alkali resistance ensure that the belts are not damaged prematurely by harsh material properties.

● Metallurgical Industry:

In the metallurgical industry, especially for transporting iron ore and coal dust, solid woven conveyor belts are an ideal choice due to their wear resistance and anti-static properties.

■ Product Features

Zoomry's solid woven conveyor belts incorporate advanced technology and high-quality materials in their design and manufacturing, with the following features:

● High Strength and Lightweight:

The thin belt body made of natural rubber offers high strength while remaining lightweight, reducing the burden on the conveyor system.

● Wear and Impact Resistance:

The PVC and PVG belts are highly resistant to wear and impact, allowing them to operate continuously and stably in high-frequency, high-load environments, reducing the need for maintenance and replacements.

● Corrosion Resistance:

The belts exhibit excellent corrosion resistance, making them especially suitable for transporting chemicals and oil products, preventing damage from material corrosion.

● Anti-Static and Fire Resistance:

PVC type belts have excellent anti-static properties, effectively preventing the risk of fire caused by static buildup, meeting fire safety requirements in underground mines and high-risk environments.

● Flexible Belt Body:

The flexible and elastic belt body maintains a stable curve during transportation, adapting to various complex conveyor paths and reducing wear during operation.

● Long Service Life:

Thanks to the use of selected materials and advanced manufacturing processes, Zoomry's solid woven conveyor belts have a long service life, reducing maintenance costs and improving equipment efficiency.

● Maintenance-Free Design:

The use of sealed bearings effectively prevents the ingress of dust and moisture, significantly reducing daily maintenance efforts and lowering operating costs.

■ Product Types

Zoomry provides a variety of solid woven conveyor belts to meet different transportation needs:

● PVC Type Solid Woven Conveyor Belt:

Coated with PVC, suitable for coal mines, power plants, and environments requiring fire and anti-static properties, with excellent wear and corrosion resistance.

● PVG Type Solid Woven Conveyor Belt:

Coated with nitrile rubber and PVC, suitable for transporting oil products, fertilizers, and other materials, offering good corrosion and oil resistance.

● High-Temperature Resistant PVC Type Solid Woven Conveyor Belt:

Designed for high-temperature environments, capable of withstanding extremely high temperatures, especially suitable for the metallurgical and steel industries.

● Corrosion-Resistant PVC Type Solid Woven Conveyor Belt:

Suitable for special environments such as the chemical and metallurgical industries, offering excellent resistance to chemical corrosion and extending the service life of the conveyor belt.

■ Product Parameters

| Strength Grade | PVC(Cover Thickness) | PVG(Cover Thickness) | Width |

| 680s/4 | 0.8+0.8 | 1.5+1.5 | 650 to 1600 |

| 800s/5 | 0.8+0.8 | 1.5+1.5 |

| 1000s/6 | 0.8+0.8 | 1.5+1.5 |

| 1250s/7 | 0.8+0.8 | 1.5+1.5 |

| 1400s/8 | 0.8+0.8 | 1.5+1.5 |

| 1600s/9 | 0.8+0.8 | 2+2 |

| 1800s/10 | 0.8+0.8 | 2+2 |

| 2000s/11 | 0.8+0.8 | 2+2 |

| 2240s/12 | 0.8+0.8 | 2+2 |

| Tensile Strength(N/mm) | Warp / Weft Direction(N/mm) | Min. Pulley Dia.(mm) |

| 680 | 680/265 | 320 |

| 800 | 800/280 | 400 |

| 1000 | 1000/300 | 500 |

| 1250 | 1250/350 | 500 |

| 1400 | 1400/350 | 630 |

| 1600 | 1600/400 | 750 |

| 1800 | 1800/400 | 800 |

| 2000 | 2000/400 | 800 |

| 2240 | 2240/450 | 1000 |

| 2500 | 2500/450 | 1000 |