A lagged pulley is a pulley that has a layer of special material applied to its surface to increase the friction and grip between the pulley and the conveyor belt. This product is widely used in industries like mining, ports, power plants, steel mills, and bulk material handling, offering excellent performance and durability. Zoomry Heavy Industry provides various types of lagged pulleys, including plain rubber, diamond grooved rubber, and ceramic rubber lagging.

Application

Lagged pulleys are primarily used in critical parts of conveyor belt systems, including head pulleys, tail pulleys, take-up pulleys, snub pulleys, and bend pulleys. The lagging material increases the friction between the pulley and the belt, preventing slippage, improving system efficiency, and protecting the pulley from wear. Lagged pulleys are used in industries such as:

- Mining Industry: In mining, particularly for transporting materials such as ores and coal, lagged pulleys effectively prevent slippage of the conveyor belt, ensuring stable operation under heavy loads.

- Ports and Terminals: In port and terminal operations, lagged pulleys ensure the stable operation of conveyor belts while reducing the impact of environmental factors such as saltwater and dust, thus improving system reliability.

- Power Industry: Lagged pulleys are commonly used in power plants to convey coal and ore. Their wear resistance and anti-slip properties help improve transportation efficiency and reduce equipment failures.

- Steel Industry: In the steel industry, lagged pulleys are used in high-temperature, heavy-load environments. They feature strong wear resistance and oxidation resistance, which helps prolong the lifespan of equipment and reduce maintenance costs.

- Bulk Material Handling: Designed for bulk material handling systems, lagged pulleys are particularly suitable for transporting materials like sand, coal, and ore. They reduce wear on the pulley and ensure the system operates smoothly over the long term.

Features

Zoomry's lagged pulleys use high-quality lagging materials and are designed with various lagging types to meet specific application requirements:

- Enhanced Friction: Lagged pulleys increase surface friction to prevent belt slippage, ensuring stable conveyor operation even under high loads and speeds. These pulleys provide strong support in heavy-duty environments such as mining, ports, and steel mills.

- Strong Wear Resistance: The lagging material has excellent wear resistance, reducing wear during prolonged use and extending the life of the pulley and conveyor belt. They are particularly effective in environments where sharp or rough materials are handled.

- Superior Anti-Slip Performance: The design of lagged pulleys significantly improves the grip between the pulley and the belt, effectively preventing slippage under high load conditions, ensuring smooth material transport.

- High Temperature Resistance: For high-temperature environments, particularly in steel mills and cement plants, Zoomry offers high-temperature lagged pulleys. These pulleys use heat-resistant materials to ensure stable operation in extreme conditions.

- Corrosion Resistance: In industries where corrosive chemicals may be present, Zoomry offers corrosion-resistant lagged pulleys made from durable materials to ensure safety and reliability while improving pulley durability.

- Low Noise Design: Zoomry lagged pulleys also feature a low-noise design, particularly in high-frequency operational environments, which helps reduce equipment noise and improve the work environment.

Product Types

Zoomry offers a variety of lagged pulleys to suit different application needs:

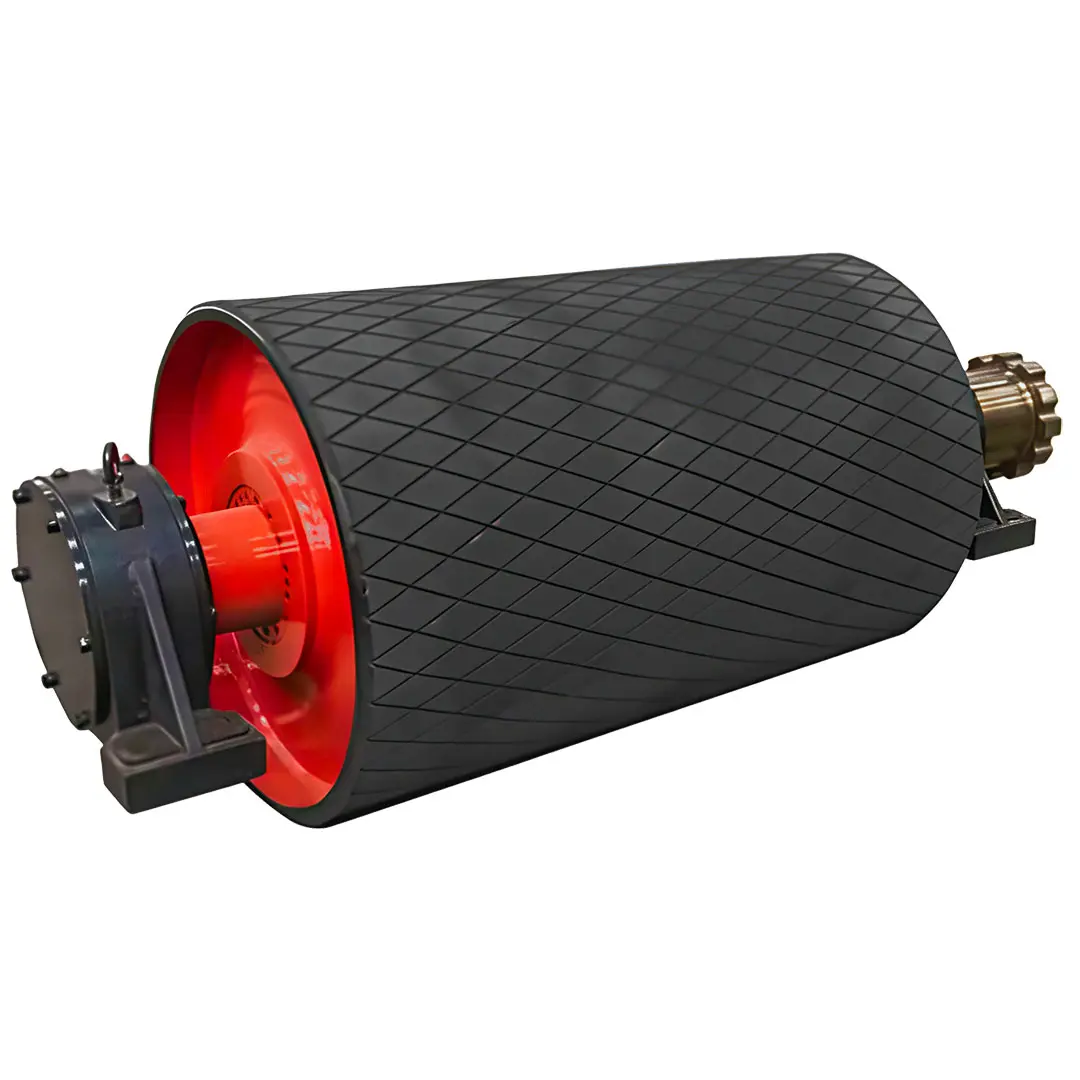

- Diamond Grooved Rubber Lagged Pulley: Featuring a diamond-pattern groove design, these pulleys are ideal for moist, dusty, and wet environments. The pattern improves traction and helps channel water and debris away from the pulley, preventing material buildup and reducing slippage.

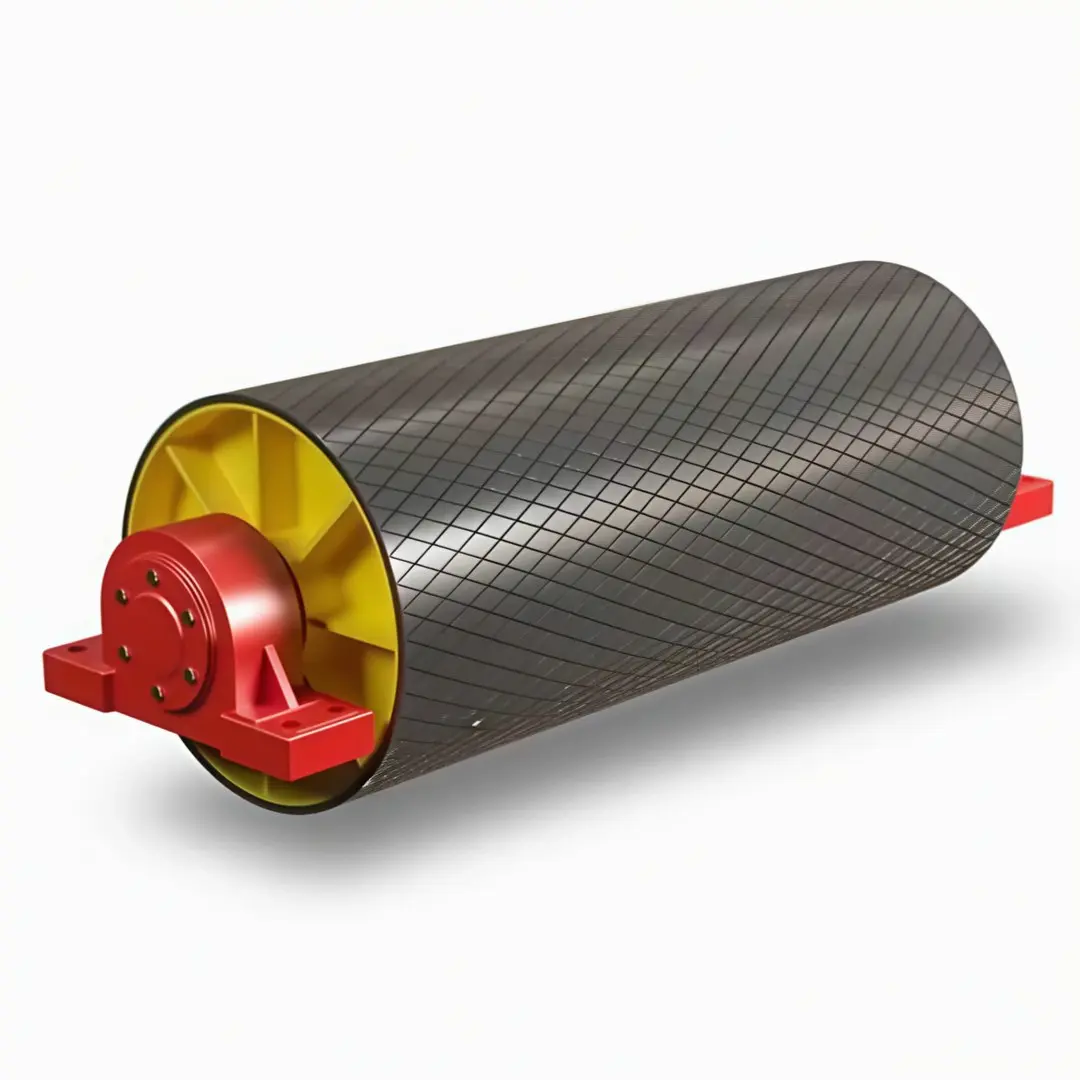

- Ceramic Rubber Lagged Pulley: Ceramic rubber lagged pulleys incorporate ceramic particles embedded in the rubber matrix, enhancing wear resistance. These pulleys are ideal for handling abrasive materials like sand and ore.

- Herringbone Rubber Lagged Pulley: The herringbone profile lagged pulley features diagonal grooves that enhance the grip between the pulley and the belt. This type is ideal for high-load or high-speed conveyor systems, providing stable material transport.

- Plain Rubber Lagged Pulley: Plain rubber lagged pulleys are the most common type, offering good traction for non-drive pulleys. They are an ideal choice for general conveyor systems due to their cost-effectiveness and versatility.

Datasheet

| Belt Conveyor Lagged Pulley Specification |

|---|

| Belt Width | 500-2800mm (19-110.2 inch) |

| Pulley Length | 500-3200mm (19-125.9 inch) |

| Diameter | 400-2200mm (15.7-86.6 inch) |

| Standard | ISO9001:2008, CEMA, DIN, TUV, JIS, AS/NS, etc. |

| Working Life | More than 30,000 hours. |

| Surface | 1. Flat Rubber Lagged;2. Ceramic & Rubber Lagged;3. Diamond Grooved Rubber Lagged;4. Chevron Pattern Rubber Lagged; 5. Spiral Grooved Rubber Lagged;6. Others |

| Main Material | Carbon Steel Shell |

| Lagged Thickness | The popular thickness is 6mm, 9mm, 12mm, 19mm, 25mm and larger (Customizable). |

| Length of conveyor Lagged pulley depends on the width of conveyor Belt. You can get Lagged pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. |

Zoomry Heavy Industry specializes in the research and production of high-quality lagged pulleys and is committed to providing customized solutions for different applications. Whether in mining, power generation, steel, or port operations, Zoomry lagged pulleys deliver exceptional performance, ensuring system stability and long-term operation. If you have any inquiries or requirements for lagged pulleys, please contact us, and Zoomry will provide professional service and product support.