The tail pulley, typically positioned at the end of a conveyor system, is primarily designed to guide the return belt and provide tension adjustment. Leveraging years of expertise in design and manufacturing, Zoomry Heavy Industry produces high-quality tail pulleys. These products, made with premium materials and advanced processes, offer excellent performance and reasonable structural design to meet the demands of various challenging conditions, ensuring the stability of conveyor systems.

APPLICATION

Zoomry's tail pulleys are widely used in various belt conveyor systems across numerous industries:

- Mining and Quarrying: In mining and quarrying applications, tail pulleys ensure stable tension under heavy-load conditions, enhancing the system's reliability. They are widely employed in handling bulk materials such as ores and coal.

- Power Plants and Cement Plants: In power plants and cement factories, tail pulleys effectively guide conveyor belts, preventing belt misalignment and slippage.

- Sand Plants and Ports: Tail pulleys in sand processing plants and port facilities ensure the smooth return of the conveyor belt while automatically adjusting tension caused by load fluctuations, ensuring high operational efficiency.

- Steel Industry: Tail pulleys provide robust support for heavy-load conveyor systems in harsh steel production environments, significantly improving transport efficiency.

- Coal Industry: Tail pulleys in coal handling systems effectively prevent reduced efficiency and equipment damage caused by belt misalignment or slack.

FEATURES

Zoomry's tail pulleys stand out with the following key features:

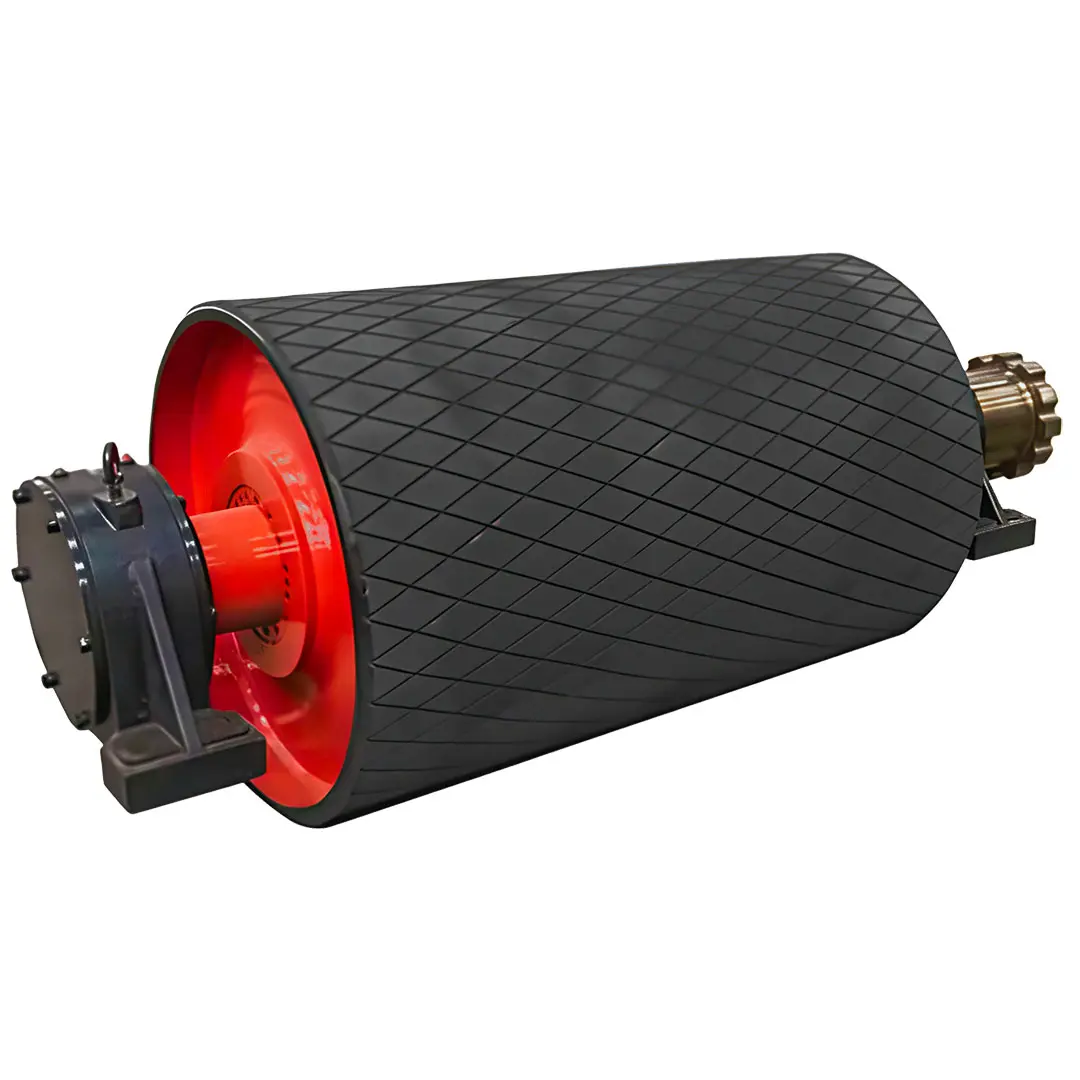

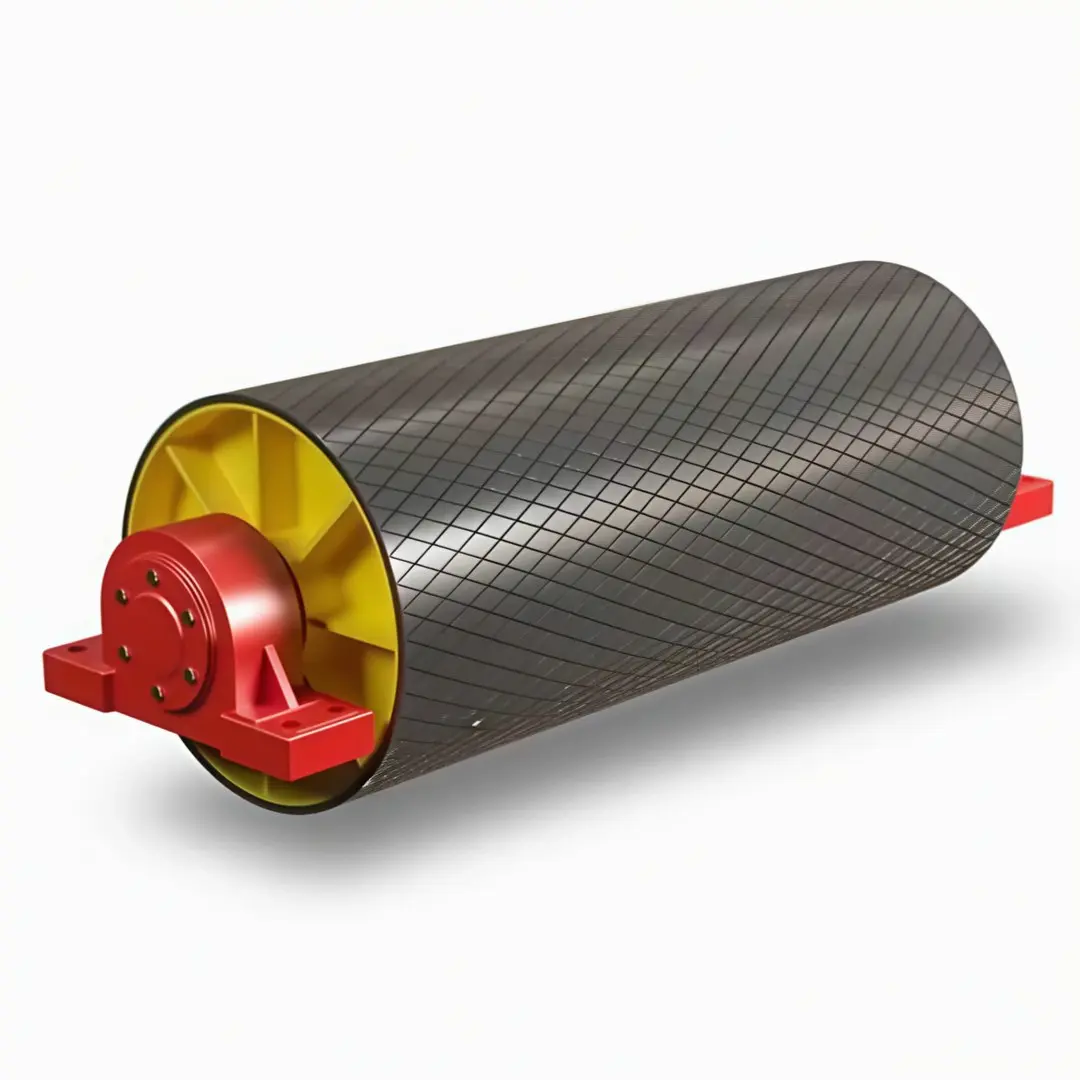

- Durability and High-Quality Materials: Tail pulleys are manufactured using high-grade steel or cast materials. The surface can be coated with highly wear-resistant rubber or ceramics, ensuring exceptional abrasion resistance in harsh environments.

- Precision Design and Tension Adjustment: Zoomry's tail pulleys feature precision-engineered structures that stabilize belt tension, effectively preventing system failures caused by insufficient or excessive tension.

- Anti-Clogging Design: Specially designed winged tail pulleys (such as spiral wings or herringbone wings) significantly reduce the risk of material entrapment between the pulley and the conveyor belt, protecting the belt and enhancing operational efficiency.

- Reliability and Low Maintenance Requirements: Equipped with high-performance bearings and precision-balanced calibration, tail pulleys ensure low noise, low vibration, and minimal downtime, reducing overall maintenance costs.

- Versatility: Zoomry offers a wide range of tail pulleys, including traditional drum pulleys and winged pulleys, to suit various conveyor systems and operating conditions.

- Customization Options: For specific applications, Zoomry provides tailored solutions, including custom dimensions, materials, and surface treatments, to meet diverse operational needs.

TYPES OF TAIL PULLEYS

Based on application scenarios and specific requirements, Zoomry's tail pulleys are categorized into the following types:

- Traditional Drum Tail Pulley: With a smaller diameter than the drive pulley, this type is made of high-strength steel and features a wear-resistant rubber or ceramic coating. Installed at the end of the conveyor, it serves as an economical and practical solution for guiding return belts and tension adjustment in various industries.

- Winged Tail Pulley: Including heavy-duty, spiral, chevron, and herringbone types, winged pulleys are specially designed to expel loose material and reduce maintenance frequency, thereby extending the service life of the equipment.

- Spiral Tail Pulley: The spiral design effectively cleans attached material from the conveyor belt, making it ideal for systems handling dusty or slippery materials, enhancing operational stability and belt cleanliness.

- Combination Tail Pulley: Merging the advantages of traditional and winged pulleys, it offers stable tension adjustment alongside efficient anti-clogging performance, suitable for demanding applications.

PRODUCT PARAMETERS

| Belt Conveyor Tail Pulley (Return Pulley) |

|---|

| Belt Width | 500-2800mm (19-110.2 inch) |

| Pulley Length | 500-3200mm (19-125.9 inch) |

| Diameter | 400-2200mm (15.7-86.6 inch) |

| Standard | ISO9001:2008, CEMA, DIN, TUV, etc. |

| Working Life | More than 30,000 hours. |

| Surface | Flat Rubber Lagged, Ceramic Lagged, Diamond Rubber Lagged, etc. |

| Main Material | Carbon Steel Shell |

| The selection and design of the tail pulley should be tailored to the specific requirements of the conveyor system, including factors such as load capacity, belt tension, and environmental conditions. Length of conveyor Tail pulley depends on the width of conveyor Belt. You can get Tail pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. |

Zoomry Heavy Industry is dedicated to delivering high-performance tail pulleys and related conveyor equipment. With superior product quality and attentive customization services, we aim to help clients optimize their conveyor system's efficiency and reduce overall operating costs. Feel free to contact us for inquiries or collaborations!