Bend pulleys are primarily used to change the direction of the conveyor belt when it passes through curves or turns. Typically installed at the head, tail, or other directional change points in conveyor systems, bend pulleys effectively assist the belt in maintaining proper alignment, preventing belt deviation, and enhancing system efficiency. As a leading brand in bulk material handling, Zoomry offers high-quality bend pulleys in various specifications and materials, designed to meet diverse working conditions and widely applied in various industrial conveyor systems.

APPLICATIONS

- Aggregate & Sand Production: In sand and gravel yards or manufactured sand production lines, conveyor belts often need to bypass equipment or turn corners. Bend pulleys optimize the turning path of the conveyor belt to ensure efficient and stable material transfer.

- Mining & Mineral Processing: During mining and mineral processing, conveyor systems must traverse complex terrains or transport materials over long distances. Bend pulleys reduce belt tension and wear, ensuring the system's reliability and durability.

- Food Processing Industry: In food production lines, conveyor belts often require tight-radius turns to optimize layouts. Bend pulleys made of corrosion-resistant and food-grade materials ensure compliance with hygiene and safety standards in the food industry.

- Warehousing & Logistics: In logistics centers and large warehouses, conveyor belts often navigate corners for flexible material transfer. Precision-designed bend pulleys enhance conveyor efficiency, meeting the demands of high-frequency operations.

- Manufacturing Production Lines: In industries such as electronics and home appliances, bend pulleys are manufactured with high precision, ensuring smooth material transfer and minimizing product damage.

- Ports & Terminals: Bulk material transport in ports demands high-capacity and efficient conveyor systems. Bend pulleys, with their robust structure and exceptional durability, adapt well to harsh environmental conditions, such as sea humidity and dust.

FEATURES

- Design Matching Belt Curvature: Zoomry's bend pulleys feature an optimized convex design, perfectly matching the belt's curve radius. This minimizes the risk of belt deviation and significantly reduces belt tension and fatigue.

- Flexible Installation Locations: Bend pulleys can be flexibly installed at the conveyor's head, tail, or directional turning points. They are tailored to the conveyor system's layout, offering efficient and stable solutions for customers.

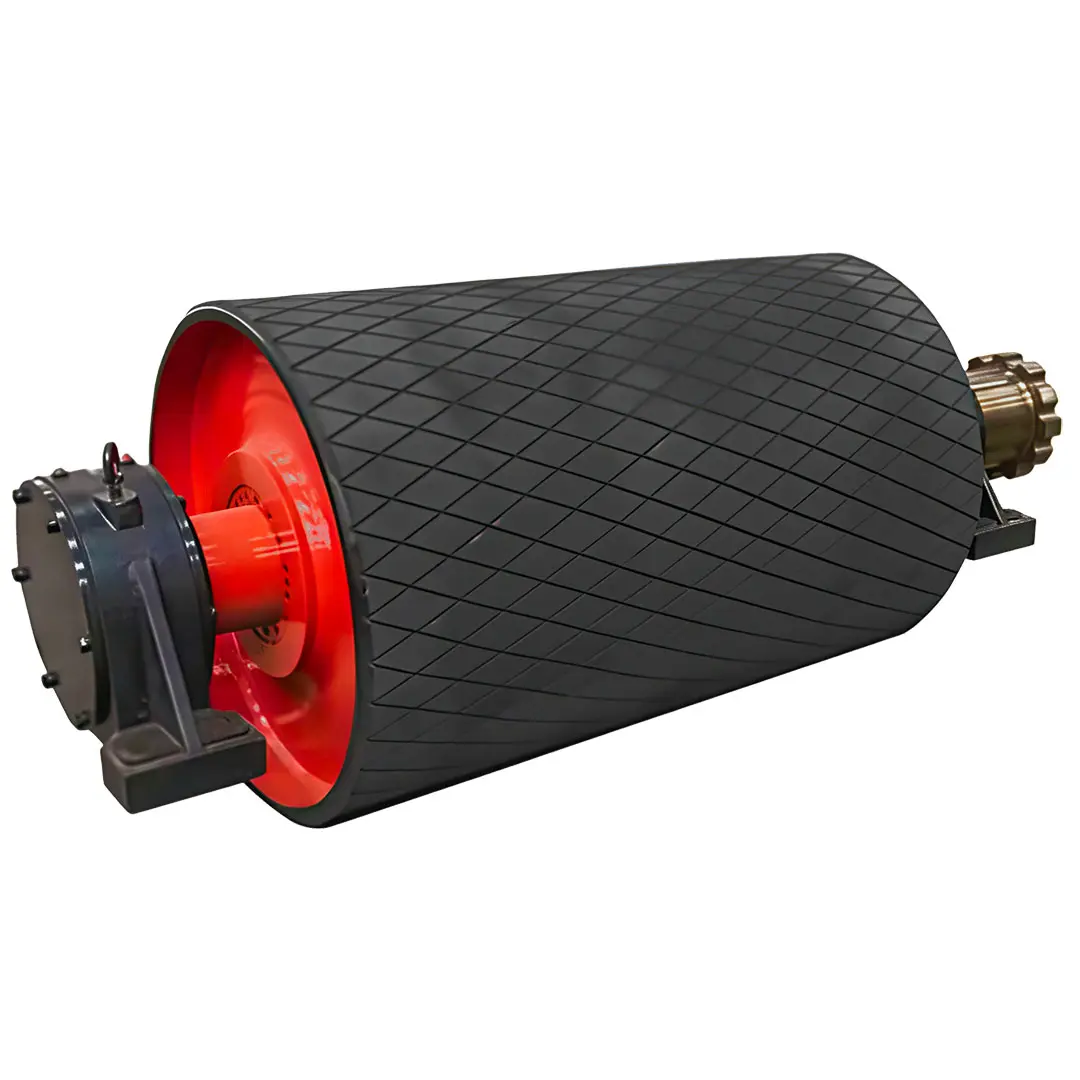

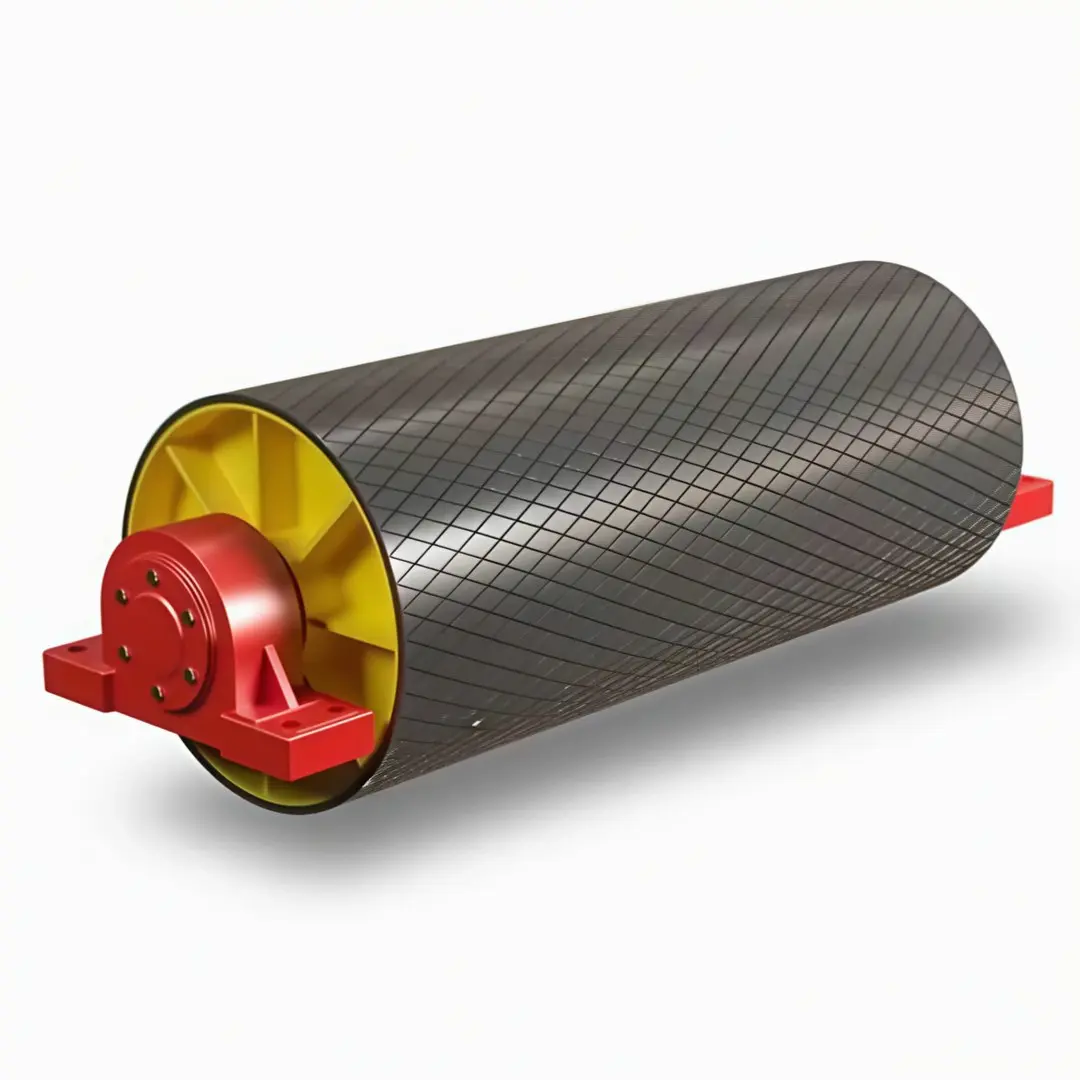

- Surface Lagging Options: Depending on customer requirements, Zoomry's bend pulleys can be equipped with rubber, ceramic, or other lagging materials to enhance friction between the pulley and the conveyor belt, improving operational stability and efficiency.

- High-Strength Materials and Construction: Typically constructed with premium steel, bend pulleys can withstand high load pressures and environmental impacts. Zoomry also offers anti-corrosion coatings to extend service life in high-humidity or corrosive environments.

- Modular Design: Featuring a modular structure, bend pulleys are easy to assemble and maintain. Adjustments for size or material upgrades can be made quickly to meet specific customer needs, saving time and costs.

- Safety Protection Measures: Zoomry incorporates comprehensive safety measures in its bend pulley designs, including protective guards and mechanical braking devices, ensuring safety for both personnel and equipment.

- Eco-Friendliness and Durability: Using energy-efficient materials and advanced manufacturing processes, Zoomry significantly reduces operational energy consumption and environmental impact while ensuring stability and durability under harsh conditions.

PRODUCT TYPES

Zoomry's Bend Pulley products are available in various types to meet different conveyor system requirements:

- Standard Bend Pulley: Suitable for general industrial environments, it features a simple structure and easy installation, widely used for conventional material handling.

- Corrosion-Resistant Bend Pulley: Designed for industries like chemicals and food processing that require corrosion resistance, it uses high-quality anti-corrosive materials and special coatings to ensure stability in harsh environments.

- Heavy-Duty Bend Pulley: Ideal for high-load, high-capacity conveyor applications, it boasts robust construction and withstands high tension and heavy impacts, particularly in mining and port operations.

- High-Temperature Bend Pulley: Specifically engineered for high-temperature environments, such as metallurgy and cement industries, it uses heat-resistant materials and special heat-dissipating structures to minimize deformation risks caused by heat.

- Lagged Bend Pulley: Equipped with rubber, ceramic, or polyurethane lagging, it enhances friction with the conveyor belt, reducing slippage and adapting to complex working conditions.

- Customized Bend Pulley: Zoomry provides professional design and manufacturing services, tailoring pulley dimensions, materials, and surface treatments to meet diverse application needs.

PRODUCT PARAMETERS

| Conveyor Bend Pulley |

|---|

| Belt Width | 500-2800mm(19-110.2 inch) |

| Pulley Length | 500-3200mm(19-125.9 inch) |

| Diameter | 400-2200mm(15.7-86.6 inch) |

| Standard | ISO9001:2008, CEMA, DIN, TUV, etc. |

| Working Life | More than 30,000 hours. |

| Surface | Flat Rubber Lagged, Ceramic Lagged, Diamond Rubber Lagged, etc. |

| Main Material | Carbon Steel |

| Length of conveyor bend pulley depends on the width of conveyor Belt. You can get drive pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. |

Zoomry Heavy Industry continually drives innovation to deliver high-performance bend pulleys and other conveyor equipment to customers worldwide. Our products undergo rigorous quality testing and are widely applied across various industries, enabling clients to achieve efficient and reliable material handling solutions. For more information, please feel free to contact us!