A snub pulley is typically installed at the head or tail end of the conveyor, close to the drive pulley. Its primary function is to increase the wrap angle of the conveyor belt around the drive pulley, thereby enhancing transmission efficiency. Designed to improve friction between the conveyor belt and the drive pulley, the snub pulley effectively prevents belt slippage, improving traction and operational stability. Zoomry Heavy Industry provides high-quality snub pulleys, suitable for various industrial fields, offering reliable conveying solutions for customers.

Applications

Snub pulleys are widely used in various industrial sectors, particularly excelling in scenarios that require heavy-load transportation and long-distance conveying.

- Mining Industry: In mining operations, snub pulleys can withstand harsh environmental conditions such as dust and moisture, ensuring efficient operation of the conveyor system. Their robust design can handle the long-term impact and load of heavy materials like ore and coal.

- Cement and Aggregate Industry: In cement plants and aggregate facilities, snub pulleys enhance conveyor efficiency by increasing the wrap angle while reducing belt wear, thereby extending equipment lifespan.

- Ports and Terminals: In port loading and unloading operations, snub pulleys enhance the traction of conveyor belts for handling bulk materials like coal and minerals, ensuring efficient completion of tasks.

- Power Plants: In fuel transport systems of thermal or nuclear power plants, snub pulleys ensure continuous and stable conveying by improving the friction between the belt and the drive pulley, playing a critical role in fuel delivery.

- Steel and Metallurgy Industry: Steel plants often involve high-temperature and heavy-load environments. Snub pulleys meet the demanding requirements of the metallurgy industry with their superior durability and stability, aiding in the rapid and efficient transport of steel materials.

Features

- Flexible Installation Position: Snub pulleys are typically installed at the conveyor head or tail, close to the drive pulley. The installation angle can be adjusted according to actual operating conditions to achieve optimal performance and ensure smooth system operation.

- Enhanced Wrap Angle Design: Snub pulleys are specifically designed to increase the wrap angle of the conveyor belt around the drive pulley, thereby increasing the contact area between the belt and the pulley to enhance friction and effectively prevent belt slippage.

- Improved Friction and Traction: By increasing the wrap angle, snub pulleys significantly improve the friction between the conveyor belt and the drive pulley, ensuring efficient operation of the conveying system.

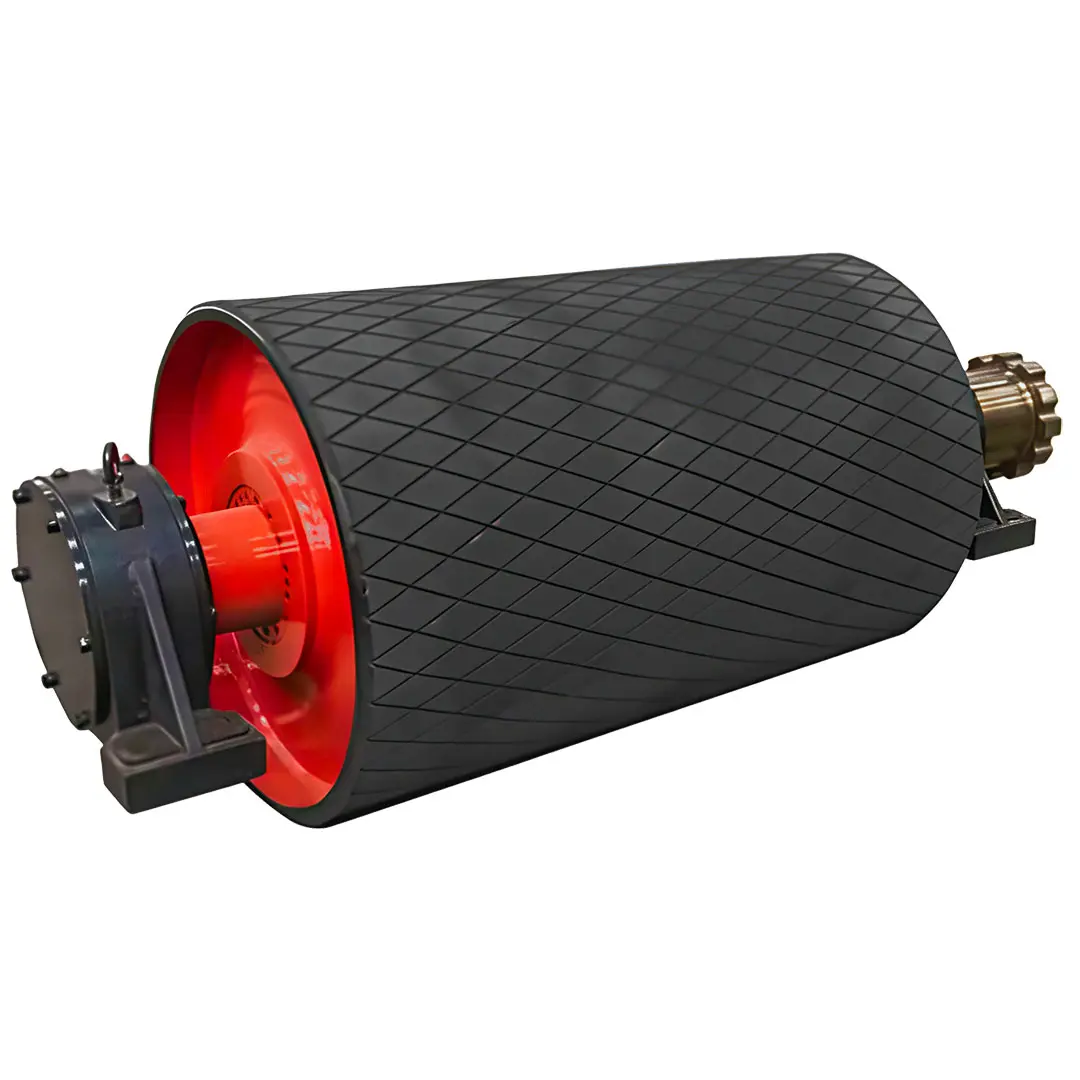

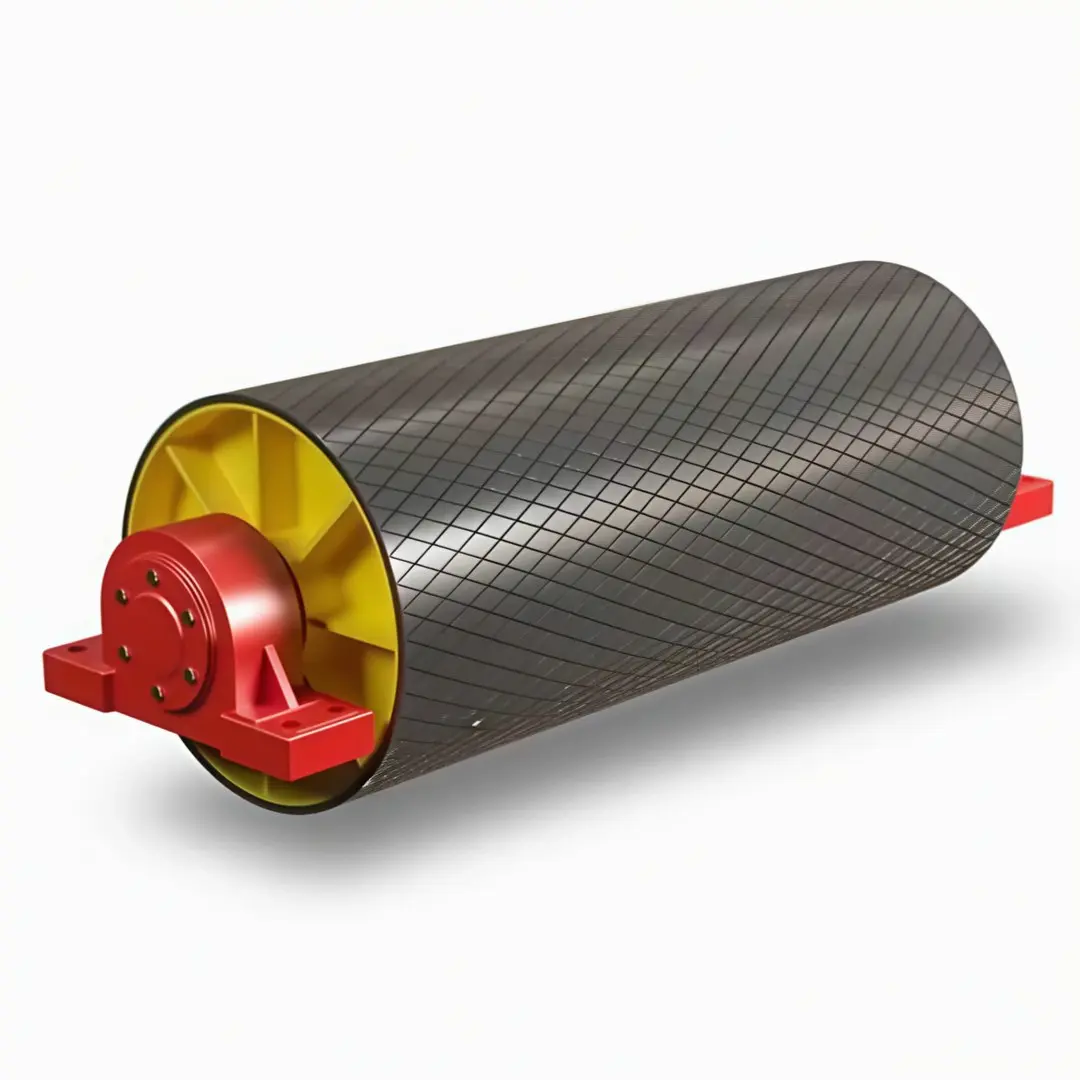

- Durability: Manufactured with high-strength materials, snub pulleys feature a specially treated surface for excellent wear resistance and corrosion resistance, making them suitable for long-term operation in harsh conditions.

- Modular Design: Snub pulleys are designed for easy on-site installation and maintenance. They are available in various specifications and support customization to meet diverse client requirements.

- High Operational Stability: Zoomry’s snub pulleys are engineered with system balance and stability in mind, reducing vibration and noise to further improve conveying efficiency.

- Energy Efficiency: Through optimized design, snub pulleys reduce energy consumption during conveyor belt operation, lowering system load and achieving energy-saving effects while extending the lifespan of conveyor equipment.

Product Types

- Standard Snub Pulley: Suitable for general conveying requirements, it features a simple structure and reliable operation, making it widely applicable in industries like coal mining, cement, and ports.

- Heavy-Duty Snub Pulley: Designed for high-load, high-impact conditions, this type is ideal for industries like mining and metallurgy, delivering outstanding durability and stability.

- Corrosion-Resistant Snub Pulley: Made with special anti-corrosion materials and coatings, it is suitable for environments with moisture and corrosive media, such as chemical plants and ports.

- High-Temperature Snub Pulley: Developed for high-temperature environments in the steel and cement industries, the pulley material features heat-resistant properties to ensure proper operation under extreme conditions.

- Adjustable Snub Pulley: Designed for flexible adjustment in conveyor systems, allowing users to modify the wrap angle as needed to achieve optimal conveying results.

- Custom Snub Pulley: Tailored to specific working conditions and requirements, customization includes dimensions, materials, and surface treatments to meet the unique demands of different industrial applications.

Product Parameters

| Belt Conveyor SnubPulley |

|---|

| Items | Content |

| Belt Width | 500-2800mm (19-110.2 inch) |

| Pulley Length | 500-3200mm (19-125.9 inch) |

| Diameter | 400-2200mm (15.7-86.6 inch) |

| Standard | ISO9001:2008, CEMA, DIN, TUV, etc. |

| Working Life | More than 30,000 hours. |

| Surface | Flat Rubber Lagged, Ceramic Lagged, Diamond Rubber Lagged, etc. |

| Main Material | Carbon Steel Shell |

| Length of conveyor Snubpulley depends on the width of conveyor Belt. You can get Snubpulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. |

Zoomry Heavy Industry is committed to providing high-quality conveyor equipment and accessories, including snub pulleys. Our products are trusted by customers for their excellent performance and reliability. If you need more technical details or customized solutions for snub pulleys, feel free to contact us.