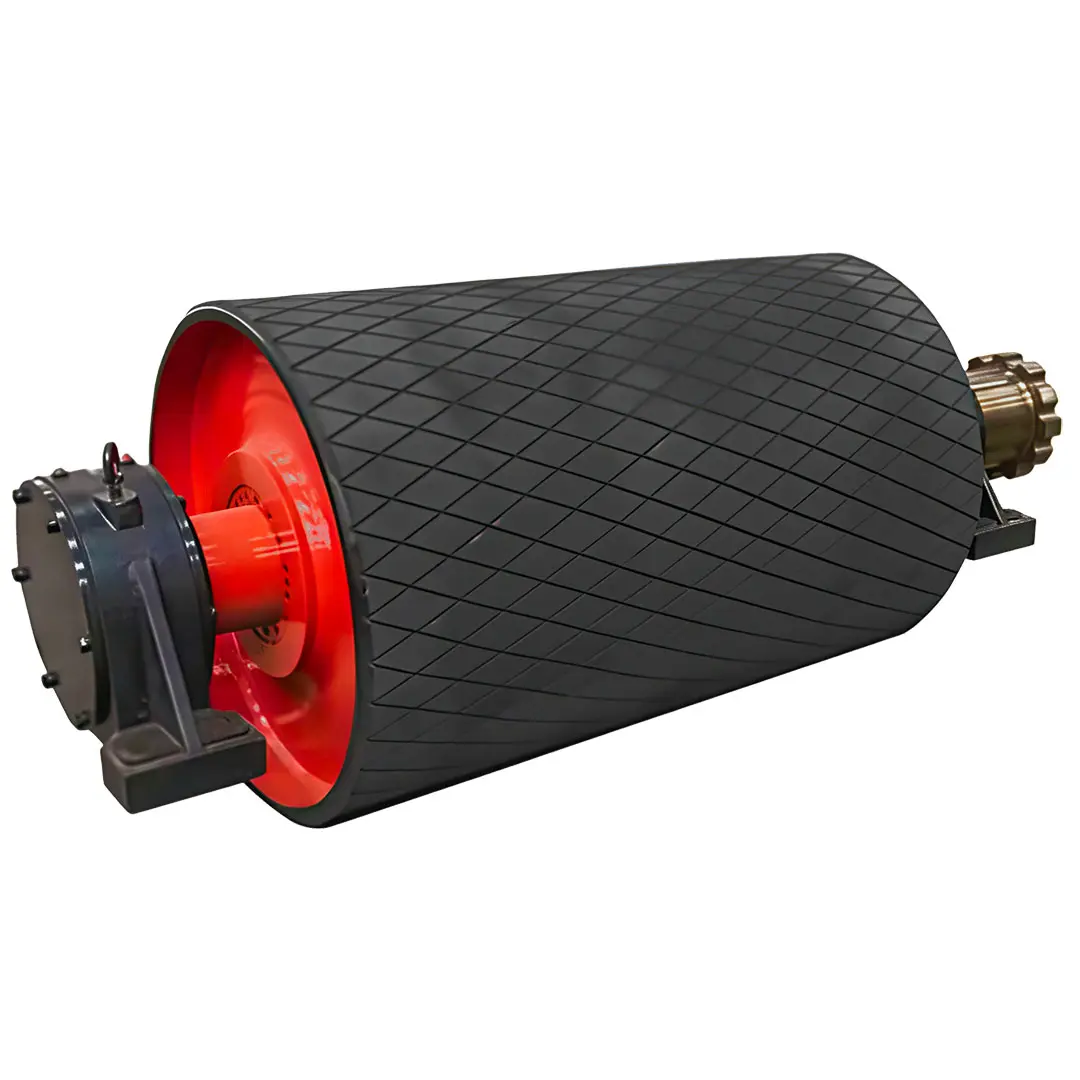

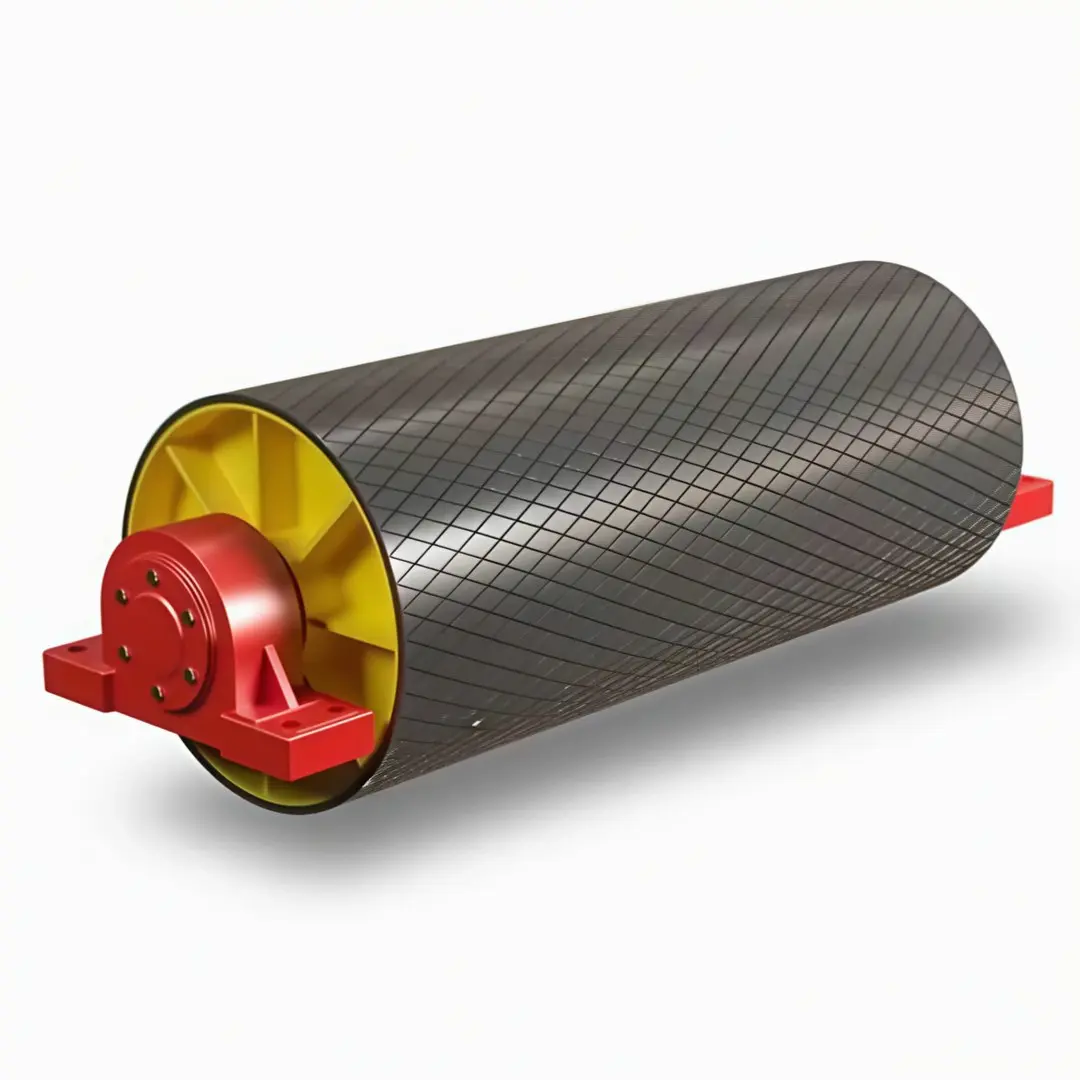

The motorized pulley, also known as a motor drum, is a conveyor drive component that integrates the electric motor, gearbox, and other mechanical parts within the drum shell. Unlike traditional external motor-driven systems, the motorized pulley encapsulates all the power transmission components inside the drum, effectively reducing the need for external mechanical structures and cables, making the drive system more compact and reliable. The motorized pulley can be widely used in various environments, especially in industries where minimizing external components or protecting equipment from harsh environmental conditions is required.

Compared to traditional drive systems, the motorized pulley exhibits greater stability and durability during operation. The sealed design effectively prevents the intrusion of dust, moisture, oil, and other harmful substances, making it ideal for tougher working environments. As an innovative product from Zoomry Heavy Industry, the motorized pulley offers more efficient and safer conveying solutions, with notable applications across various industries.

Applications

Motorized pulleys are widely applied, especially in industries such as mining, ports, recycling, construction demolition, and cement, due to their compact design, ease of maintenance, and ability to provide efficient power.

- Mining Industry: Motorized pulleys can operate reliably in harsh environments, particularly in humid and dusty conditions. Their sealed design effectively prevents dust and moisture from entering, thereby extending the lifespan of the equipment.

- Ports and Maritime: During cargo handling at ports, motorized pulleys provide reliable driving power, especially for conveying heavy materials such as ores and coal. Their energy-efficient and high-performance characteristics are well-suited for modern port conveyor systems.

- Recycling Industry: Motorized pulleys operate efficiently in waste handling and recycling systems, reducing the reliance on external power transmission systems and lowering maintenance costs.

- Cement Industry: In cement production processes, motorized pulleys deliver stable power, ensuring efficient material transportation. Their robust and durable design ensures consistent performance even under high-load conditions.

- Construction Demolition: In the construction demolition industry, motorized pulleys help quickly move construction debris, improving work efficiency.

Features

- Compact and Efficient: Compared to traditional external motor-driven systems, the motorized pulley features a compact design that saves installation space. The internal integration of components makes installation and maintenance more convenient, reducing labor costs.

- High Reliability: The sealed design of the motorized pulley protects the internal components from external factors such as dust, oil, and moisture, ensuring stable operation in various harsh environments.

- Low Maintenance Cost: As all transmission components are sealed within the drum, the motorized pulley requires minimal external maintenance. It reduces wear-and-tear parts compared to traditional systems, lowering the frequency and cost of maintenance.

- Energy Efficient: Motorized pulleys are equipped with high-efficiency motors and gearboxes that provide powerful driving force while reducing energy consumption, contributing to energy savings.

- Strong Adaptability: Motorized pulleys are suitable for various types of belt conveyors and can be customized to meet the specific needs of different industries, providing tailored solutions.

- Safety and Reliability: Particularly suitable for environments with hazardous gases, such as coal mines, the motorized pulley can be equipped with explosion-proof motors to ensure safety in high-risk areas.

Product Types

- Standard Motorized Pulley: This type of motorized pulley adopts a standard design and is suitable for most conventional material handling needs. Its compact design allows for installation in various conveyor systems, widely used in industries such as mining, ports, steel, and building materials.

- Explosion-Proof Motorized Pulley: This motorized pulley is specifically designed for environments where flammable gases or dust are present, such as coal mines and fertilizer plants. The explosion-proof motor prevents sparks or high temperatures from harming the environment, ensuring safe operation in hazardous environments.

- Ceramic Anti-Slip Motorized Pulley: Suitable for environments requiring higher traction, such as quarries and mines, this motorized pulley has a ceramic anti-slip coating on its surface, enhancing material grip and preventing slippage, improving conveying efficiency.

- Metallurgical Motorized Pulley: Designed specifically for the metallurgical industry, this motorized pulley has excellent heat resistance and corrosion resistance, enabling it to operate stably in high-temperature and harsh environments.

- Mining-Specific Motorized Pulley: This motorized pulley is designed for mining transport and has a strong load-bearing capacity and durability, allowing it to operate efficiently in complex mining environments.

Product Specifications

| Belt Conveyor Motorized Drum Pulley (Motor Drum) |

|---|

| Component | The Motorized Conveyor Drum Pulley includes pulley shell, bracket, coupler, motor and gear reducer. |

| We provide Flameproof and Normal type motorized conveyor pulleys. They are all oil-cooled drum pulleys. |

| Types | 1. Drum Motor With Internal Motor and Gearbox; 2. Drum Motor With External Motor and Gearbox Compact;3. Drum Motor With Gear-less Motor;4. Drum Motor with VFD Control Ability |

| Driving Power | 1.5~630KW(Customizable) |

| Velocity | 0.35~4.0(m/s)(Customizable) |

| Belt Width | 400mm-2600mm(Customizable) |

| Drum Diameter | 400mm-2200mm(Customizable) |

| Type conveyor | Belt Conveyor, Mobile Conveyor, Stacking Conveyor, Mobile Shiploader, etc. |

| Surface | Smooth steel surface, rubber faced, rubber lagged, ceramic lagged, diamond rubber covered. |

| Standard | ISO9001:2008, CEMA, DIN, TUV, etc. |

| Application | Used in mining, coal mine, steel industry, cement industry, aggregate industry and so on. |

| Service life | More than 30,000 hours. |

Zoomry Heavy Industry’s motorized pulleys, with their advanced design and high-efficiency technology, have been widely used in multiple industries and regions worldwide. We are committed to providing high-quality products and services to help customers improve operational efficiency, reduce costs, and enhance market competitiveness. If you are interested in our motorized pulley products, feel free to contact us for more technical details and customized solutions.