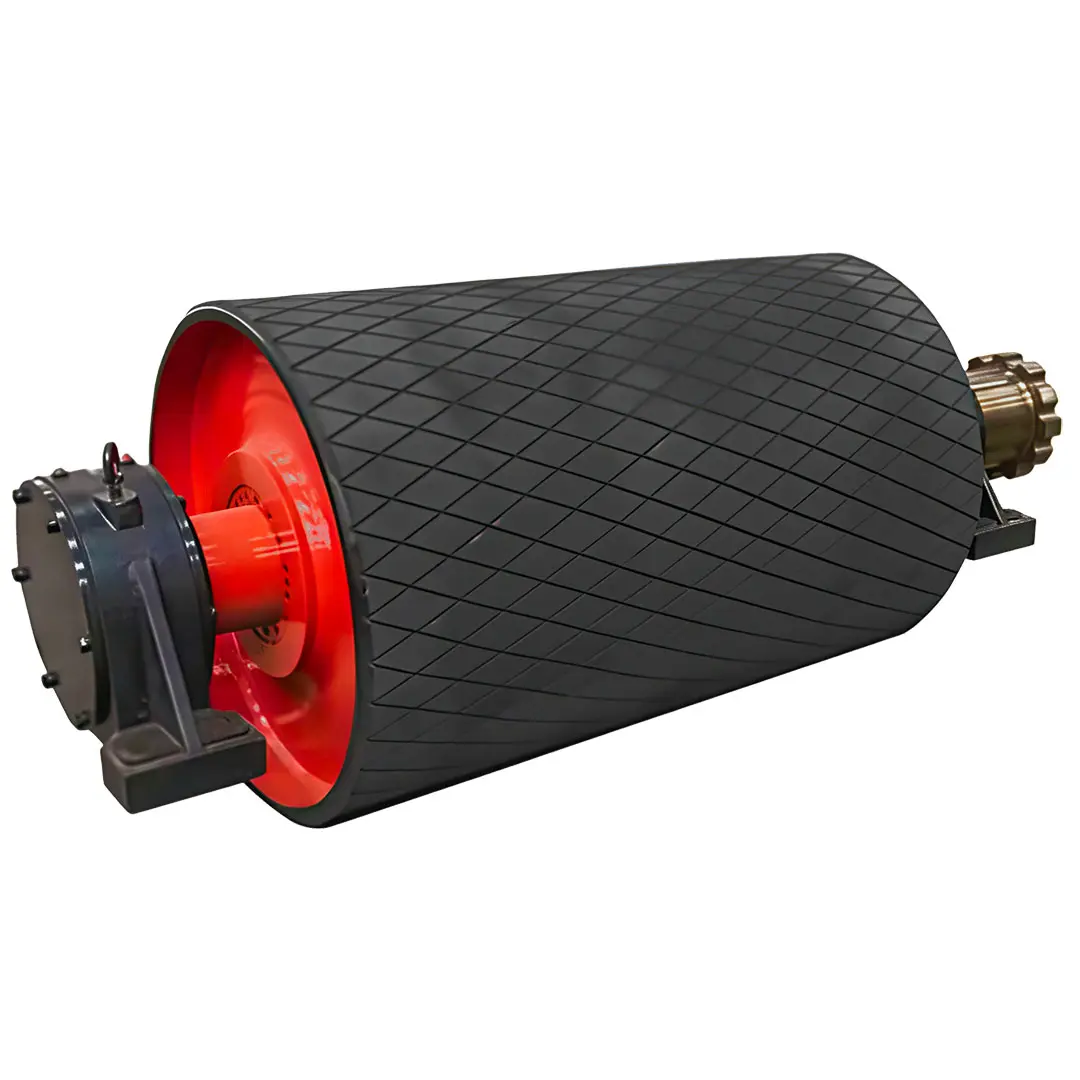

The drive pulley, also known as the head pulley or drive drum, is a crucial component of the conveyor system’s drive mechanism. It is typically connected to the motor and provides the necessary torque through a reducer to drive the motion of the conveyor belt. Zoomry Heavy Industry offers high-quality drive pulley products or complete drive systems to meet the diverse needs of our customers.

Applications

Drive pulleys are widely used in various conveyor systems, especially in environments that require efficient and continuous operation. Here are some typical industries where they are used:

- Sand and Gravel Production and Mining: In sand production, ore mining, and mineral processing, the drive pulley effectively drives the conveyor belt to transport heavy materials.

- Food Processing Industry: In food processing, conveyor belts transport ingredients, packaged products, etc., with the drive pulley providing reliable power.

- Warehousing and Logistics: In large-scale warehouses, distribution centers, and logistics systems, the drive pulley ensures rapid movement of goods.

- Manufacturing: In automated production lines within manufacturing industries, drive pulleys efficiently move materials through the production process.

- Comprehensive Logistics Applications: Drive pulleys are also widely used in sectors such as freight handling, air cargo, and other fields, offering high adaptability and reliability.

Product Features

- High-Efficiency Power Transmission: The main function of the drive pulley is to convert the motor power into rotational motion via a reducer, driving the movement of the conveyor belt. The motor is connected to the drive pulley, with the reducer adjusting the speed and torque to ensure stable and efficient belt operation.

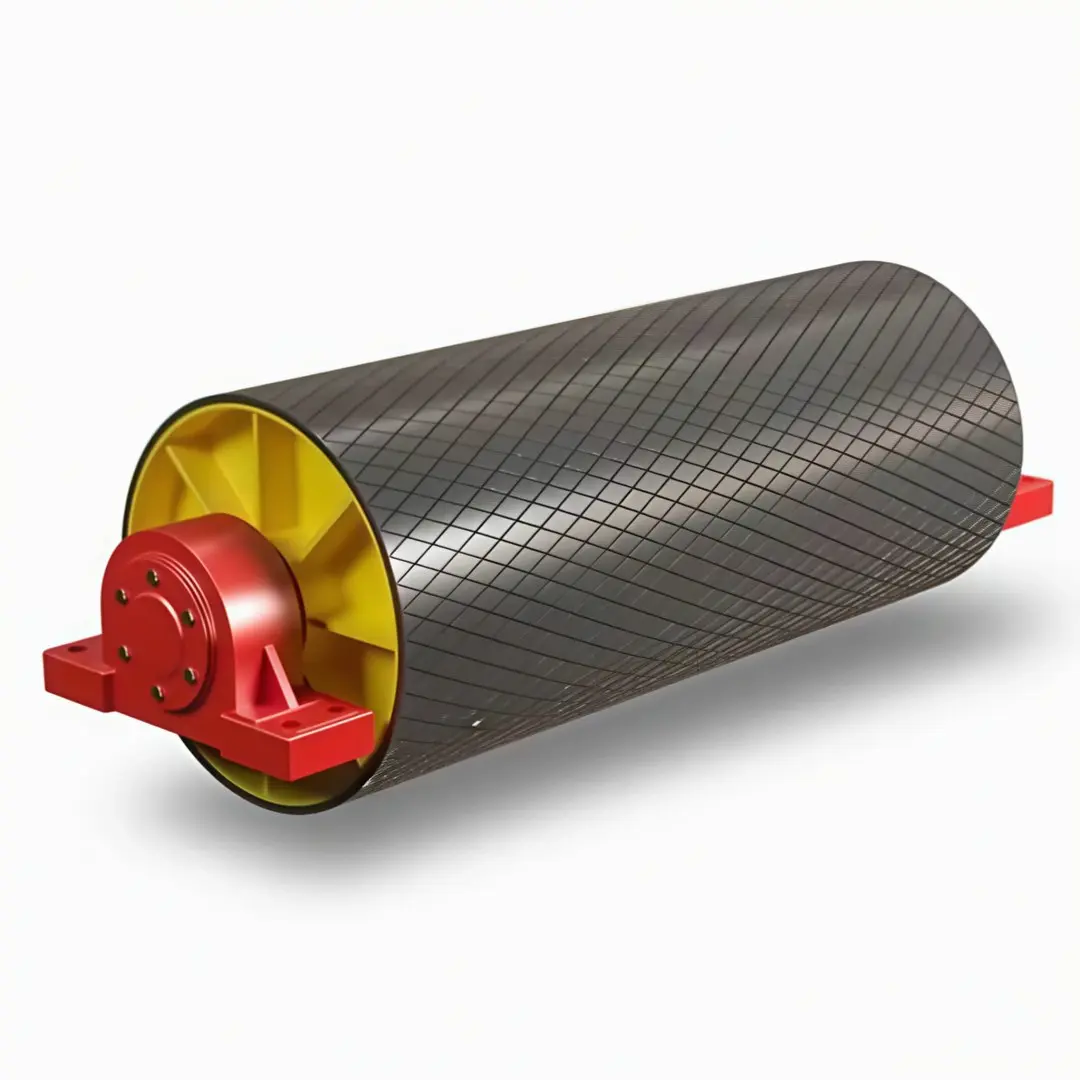

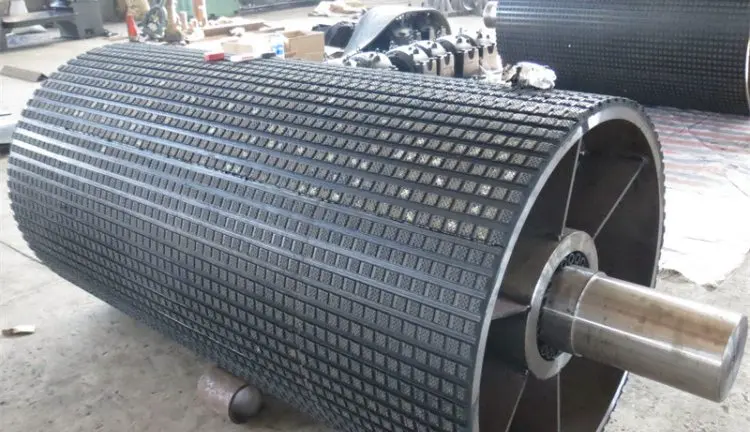

- Steel Shell Construction with Material Covering: Zoomry Heavy Industry's drive pulleys are generally made from high-strength steel, with the outer surface often covered in rubber or other wear-resistant materials to enhance friction with the conveyor belt, ensuring good traction and reducing wear. The material covering can be customized to provide additional durability, especially in harsh environments such as high temperatures or humidity.

- Robust Shaft Design: The shaft of the drive pulley is a key component responsible for load-bearing, requiring a design strong enough to withstand various forces and loads generated by the conveyor system. The high-strength design ensures stable operation even under heavy loads.

- Torque Limiting Device: To protect the system from overload, some drive pulleys are equipped with torque-limiting devices. These devices prevent excessive torque from damaging the motor and reducer, thereby extending the system's lifespan.

- Safety Design: The drive pulley is designed with safety in mind, particularly in relation to moving parts. Proper safety shields prevent contact between personnel and the pulley, minimizing the risk of accidents. All safety features meet relevant international safety standards to ensure the safety of operators.

- Low Maintenance Requirements: Zoomry Heavy Industry's drive pulleys are designed for long-term reliability, using high-durability sealing devices and protective layers that significantly reduce maintenance frequency. With superior materials and technology, the equipment operates with minimal downtime, lowering overall operational costs.

Product Types

- Standard Drive Pulley: Suitable for a wide range of conventional conveyor systems, offering high versatility and reliability.

- High-Wear Resistant Drive Pulley: Designed for high-wear environments, such as the transportation of heavy materials like ores and coal, capable of handling demanding working conditions.

- High-Temperature and Corrosion-Resistant Drive Pulley: Suitable for high-temperature or corrosive environments, such as steel mills or fertilizer plants.

- Custom Drive Pulley: Designed according to the customer's specific requirements to suit complex or specialized applications.

Product Parameters

| Belt Conveyor Drive Pulley |

|---|

| Belt Width | 500-2800mm (19-110.2 inch) |

| Pulley Length | 500-3200mm (19-125.9 inch) |

| Diameter | 400-2200mm (15.7-86.6 inch) |

| Standard | ISO9001:2008, CEMA, DIN, TUV, JIS, AS/NS, etc. |

| Working Life | More than 30,000 hours. |

| Surface | Flat Rubber Lagged, Ceramic Lagged, Diamond Rubber Lagged, etc. |

| Main Material | Carbon Steel Shell |

| Length of conveyor drive pulley depends on the width of conveyor Belt. You can get drive pulleys with hot & cold vulcanized rubber lagging, plain or grooved, as required by client. |