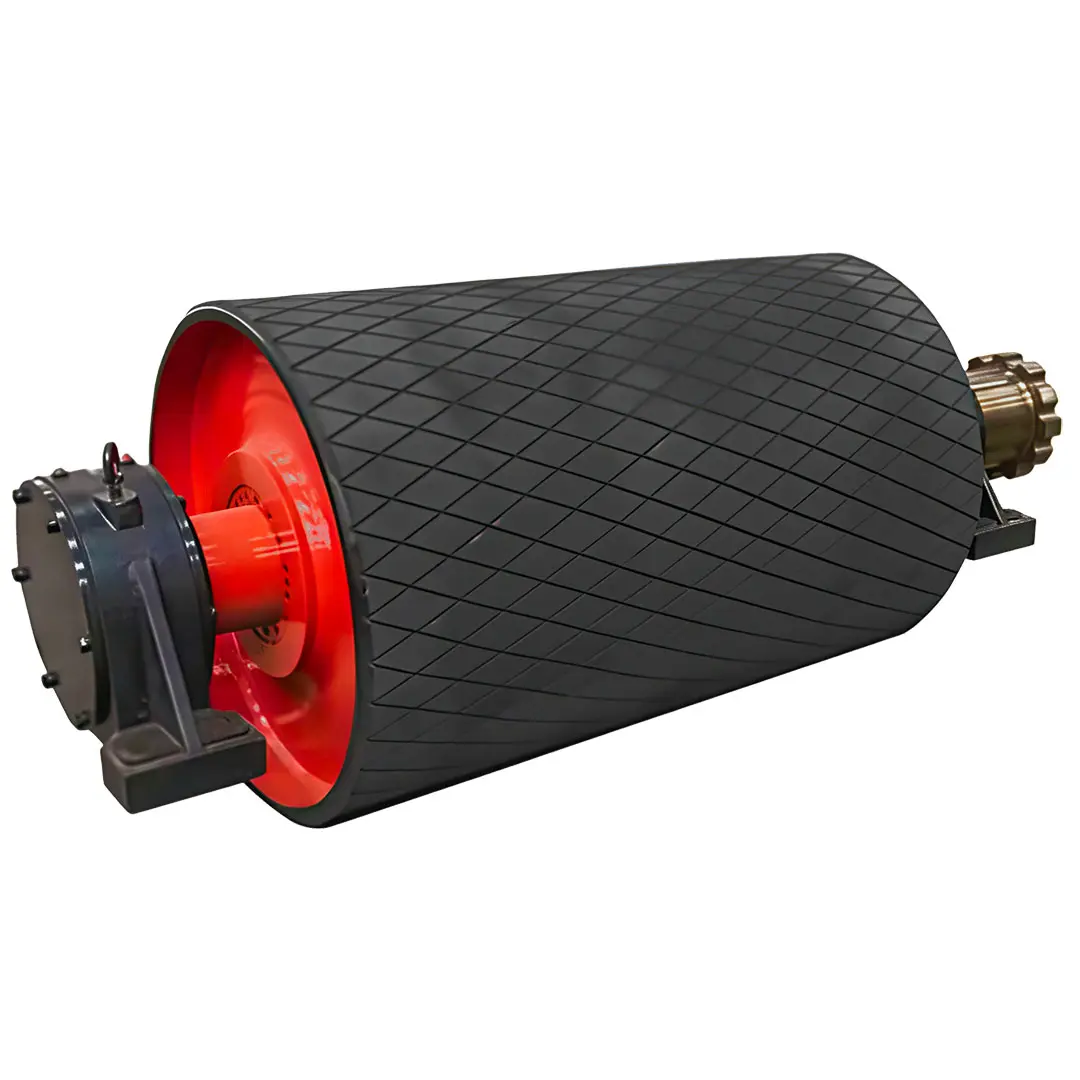

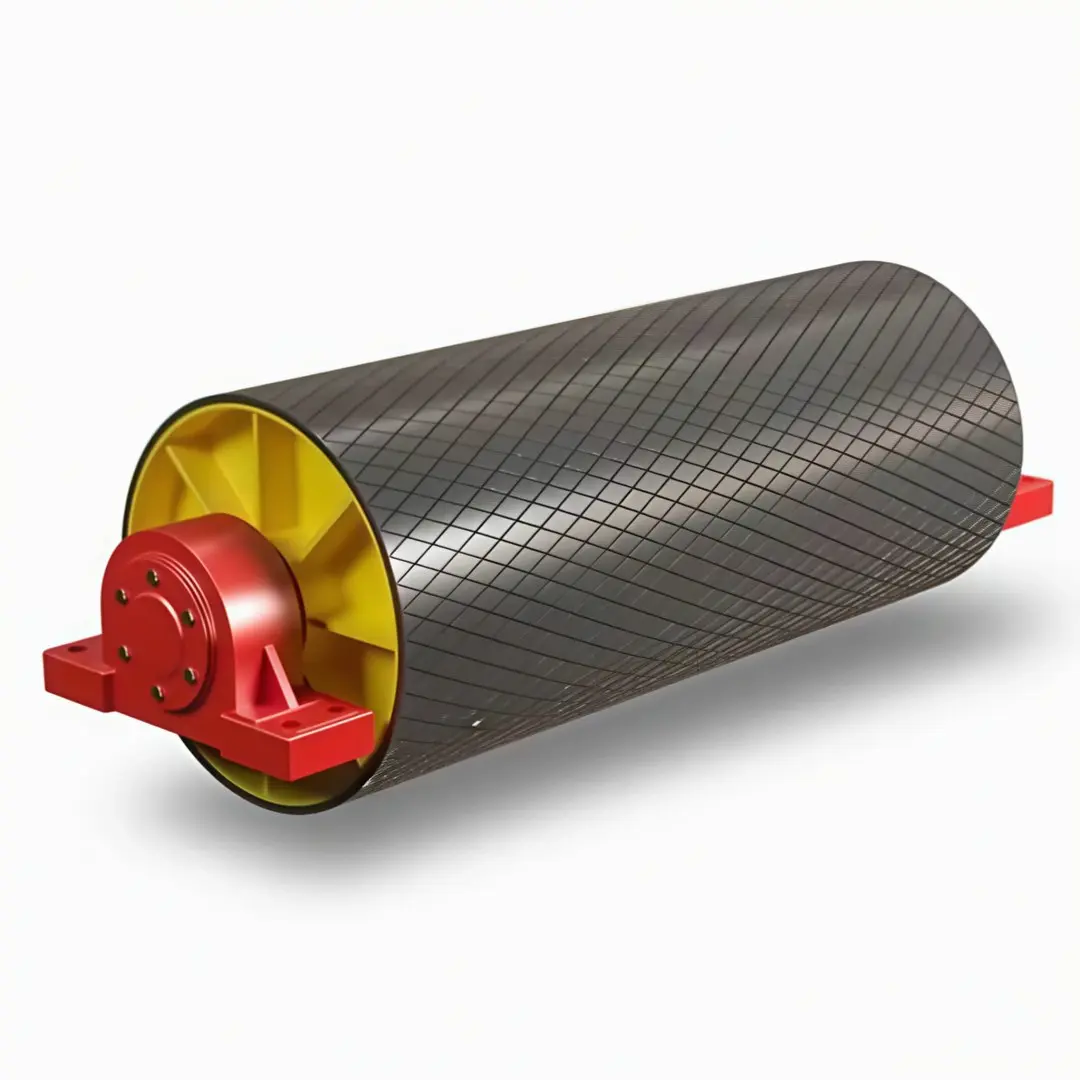

The belt conveyor head pulley is located at the discharge point of the conveyor, transmitting power from the motor to the conveyor belt, causing it to move forward and transport materials. To improve traction, the head pulley is typically lagged with rubber or ceramic materials (also known as lagging), which enhances the friction between the pulley and the conveyor belt, improving system efficiency and reducing equipment wear.

Applications

The head pulley is widely used in various industries:

- Metallurgy: Transports ores, coal, and other materials.

- Mining: Responsible for transporting minerals from mining areas to crushing or transportation points.

- Quarrying: Provides solutions for handling stone, gravel, and other materials.

- Cement and Clinker: Transports raw materials and finished cement, ensuring stable production lines.

- Construction Waste: Handles and transports construction waste, supporting environmental protection and resource recycling.

- Fertilizer: Transports raw materials and finished fertilizers in fertilizer production.

- Chemicals: Used to transport various chemical raw materials and intermediate products, ensuring continuous production.

- Aggregate and Sand: Used in the transportation of bulk materials such as sand and gravel, commonly used in construction sites and storage facilities.

Features

- Head Pulley Construction: Head pulleys are typically made of steel. The part in contact with the conveyor belt is often lagged to improve friction and reduce wear. Common lagging materials include rubber and ceramics, which not only enhance traction but also extend the life of the head pulley.

- Various Diameter Selection: The diameter of the head pulley is a crucial design factor. Larger diameter head pulleys provide more contact area, increasing the conveyor belt's grip, thus improving traction and reducing tension requirements on the drive system. Choosing the right diameter is vital for long-term, high-intensity operations.

- Robust Shaft Design: The shaft of the head pulley must be strong enough to withstand the loads and forces transferred by the conveyor system. Typically, high-strength steel is used for the shaft, ensuring stable performance under heavy-duty conditions.

- Environmental Adaptability: The working environment of the head pulley significantly impacts material selection and coating treatments. In dusty, humid, or corrosive environments, the head pulley must be made from corrosion-resistant materials or undergo special protective treatments to ensure long-term stability.

- High-Quality Bearings: Bearings are installed on the shaft of the head pulley to support smooth rotation. Depending on load, speed, and environmental conditions, users can choose bearings from renowned brands such as SKF, FAG, NSK, LYC, HRB, or ZWZ to ensure the stability and longevity of the head pulley system.

- Durability and Reliability: The design of the head pulley emphasizes not only efficiency but also durability. With high-strength materials and advanced manufacturing processes, Zoomry’s head pulleys continue to perform efficiently and reliably under extreme conditions.

- Low Maintenance Requirements: Zoomry’s head pulleys are designed to have low maintenance needs. Using high-quality seals and wear-resistant materials reduces regular maintenance and replacement cycles, helping to lower overall operational costs.

Product Types

- Standard Head Pulley: Suitable for general material handling with high performance and versatility.

- High-Wear Resistant Head Pulley: Designed for environments with high wear, such as ore and coal transportation.

- High-Temperature Resistant Head Pulley: Specially designed for high-temperature environments, suitable for steel smelting and coke industries.

- Corrosion-Resistant Head Pulley: Built for harsh environments to prevent corrosion and extend equipment lifespan.

- Custom Head Pulley: Tailored to meet specific operational conditions based on customer requirements.

Product Parameters

| Belt Conveyor Head Pulley |

|---|

| Belt Width | 500-2800mm (19-110.2 inch) |

| Pulley Length | 500-3200mm (19-125.9 inch) |

| Diameter | 400-2200mm (15.7-86.6 inch) |

| Standard | ISO9001:2008, CEMA, DIN, TUV, etc. |

| Working Life | More than 30,000 hours. |

| Surface | Flat Rubber Lagged, Ceramic Lagged, Diamond Rubber Lagged, etc. |

| Main Material | Carbon Steel Shell |

| Length of conveyor Head pulley depends on the width of conveyor Belt. You can get Head pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. |