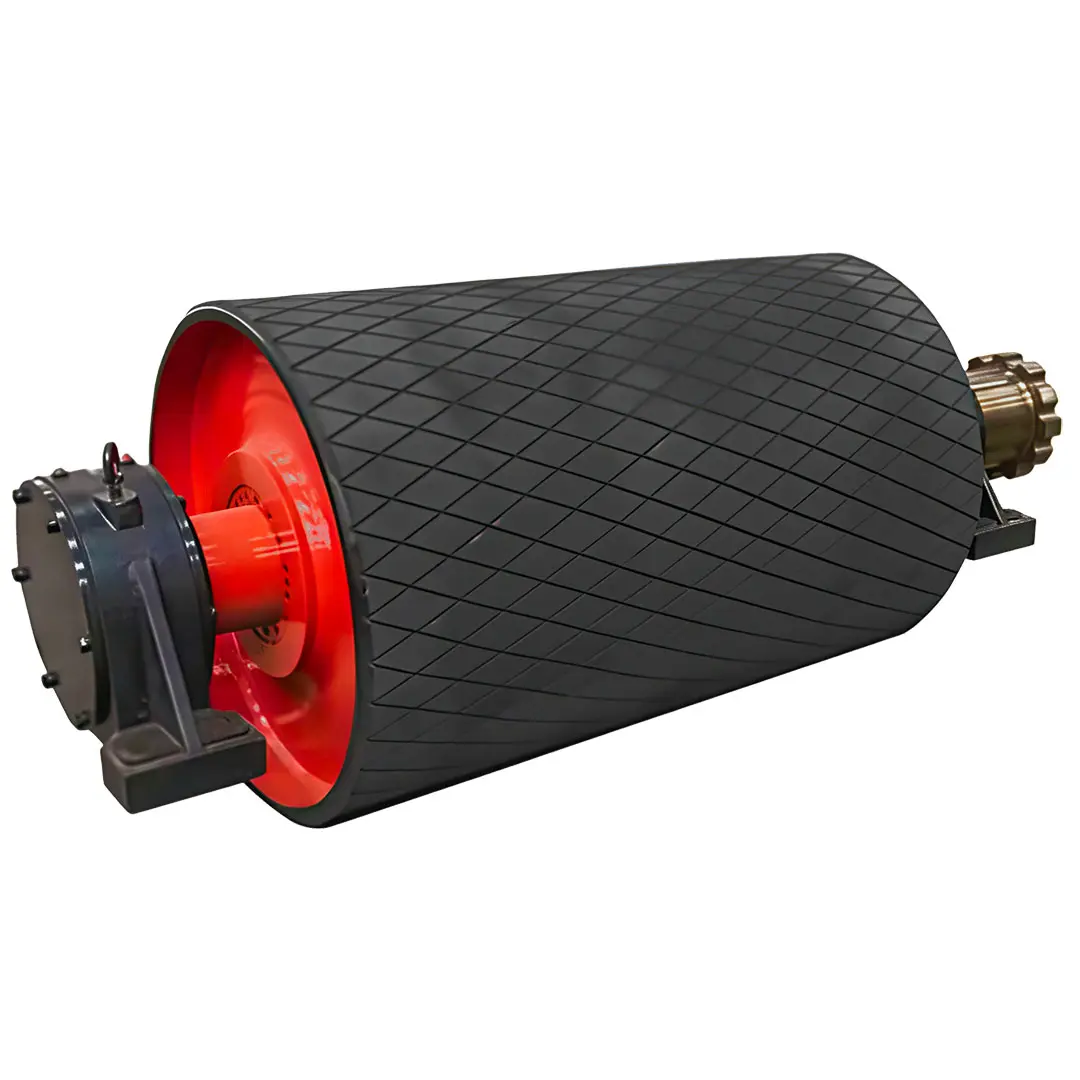

The conveyor belt pully is a key load-bearing component of the belt conveyor,similar to mechanical equipment with rotating rollers,used to change the direction of the belt in the conveying system,or to drive the belt or apply tension to the belt.Conveyor belt pullys are heavier than idler rollers and are usually located at both ends of the conveyor or near the drive/motor.

Choosing the right pully can be a headache for many people.The conveyor belt pullys produced by Zoomry meet the stringent requirements of various industries such as sandstone mines,coal mines,unit packaging,food processing,and recycling.They can avoid premature failure in harsh environments,thereby providing maximum protection.In addition,we can offer very short delivery cycles for both stock products and custom products.

Advantages

- Strict selection and inspection of raw materials

- Finite element stress analysis,targeted structural and material optimization

- Perfect quality control system

Materials

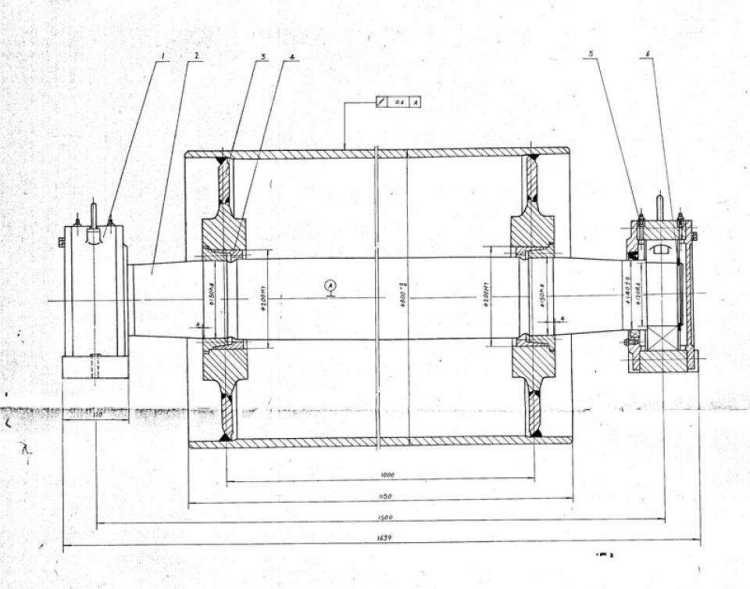

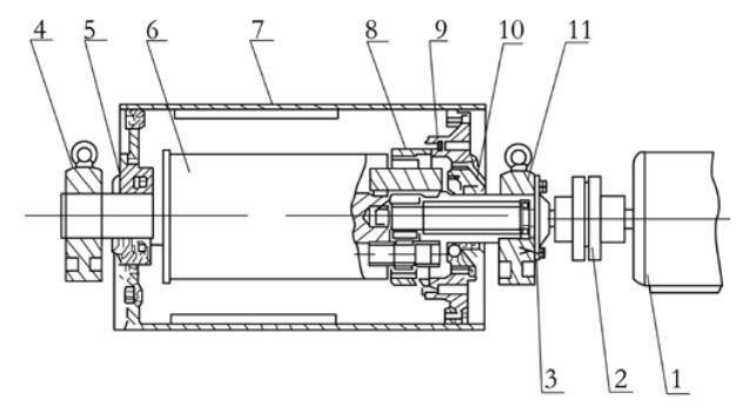

Different materials are selected according to different environments and different load-bearing capacities.The materials for pully shafts include 45#steel,40Cr,42CrMo,etc.,while the shells are made of 16Mn steel plate.

Specification Table

| Diameter of belt roller | 500mm | 650mm | 800mm | 1000mm | 1200mm | 1400mm | 1600mm | 1800mm | 2000mm | 2200mm |

|---|

| 400mm | √ | √ | √ | √ | √ | √ |

|

|

|

|

| 500mm | √ | √ | √ | √ | √ | √ | √ |

|

|

|

| 630mm |

| √ | √ | √ | √ | √ | √ |

|

|

|

| 800mm |

|

| √ | √ | √ | √ | √ | √ |

|

|

| 1000mm |

|

| √ | √ | √ | √ | √ | √ | √ |

|

| 1250mm |

|

|

| √ | √ | √ | √ | √ | √ |

|

| 1400mm |

|

|

| √ | √ | √ | √ | √ | √ |

|

| 1600mm |

|

|

|

| √ | √ | √ | √ | √ |

|

| 1800mm |

|

|

|

|

|

| √ | √ | √ | √ |

| 2000mm |

|

|

|

|

|

| √ | √ | √ | √ |

Design Features

- The coefficient of friction can be up to twice that of non-lagging pullys

- 50%higher coefficient of friction than typical rubber lagging layers

- 38%of the belt contact surface is ceramic(medium load)

- Almost no belt slippage occurs.

- Improved belt tracking

- Not prone to retaining water and dirt

- Reduces belt tension,reduces material pickup weight

- Easy installation

Types

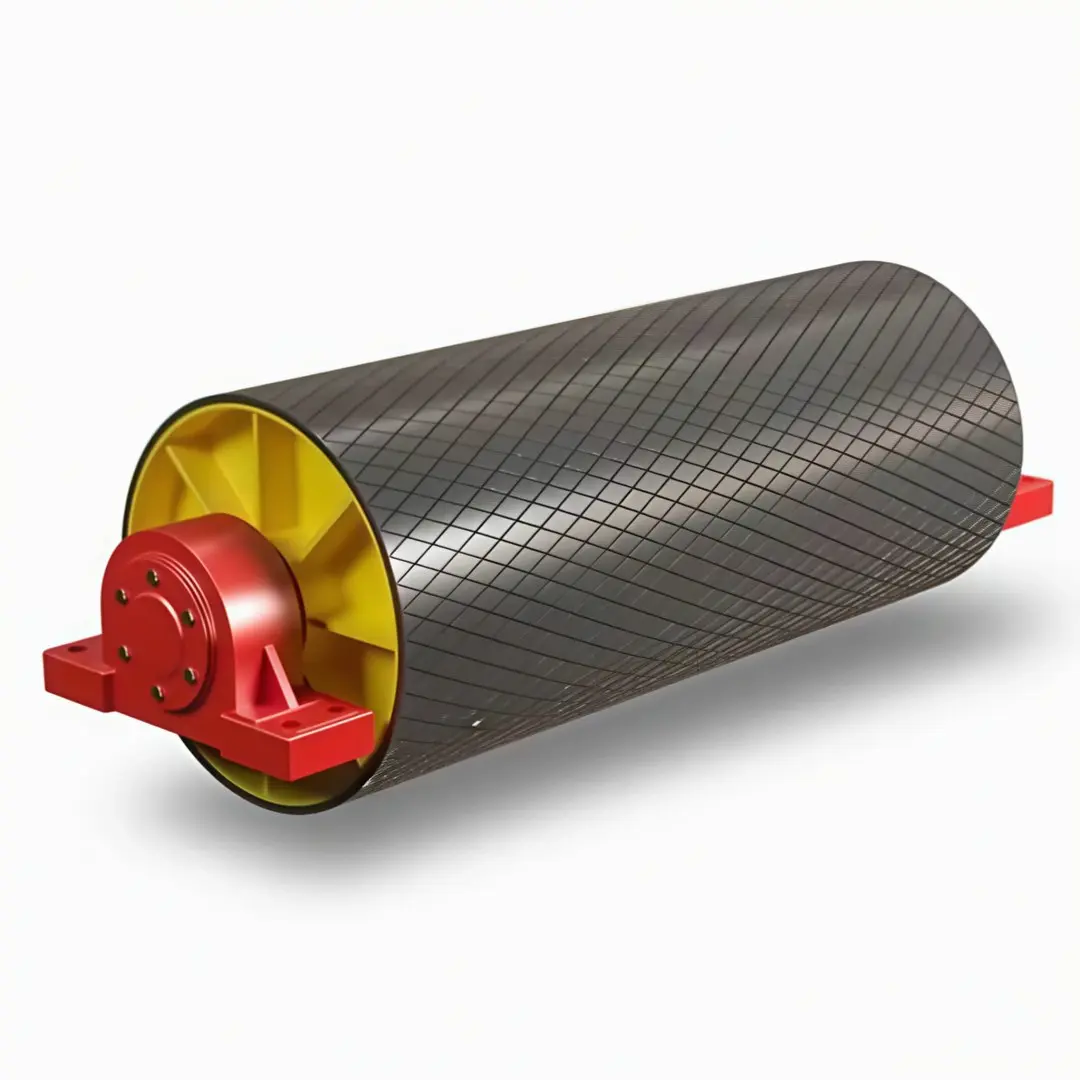

The types of pullys usually include:drive pullys,return pullys,tension pullys,bend pullys,and surface-enhanced pullys.

- Drive Pully/Head Pully: Drive pullys or head pullys are used to drive the conveyor belt.They are usually installed in profile bearings and driven by motors and reducers.Conveyor head pullys can be flat or convex,and many have rubber coating to reduce belt slippage.Conveyor roller pullys,wing pullys,and spiral pullys are the most common types of drive pullys.

- Return/Tail Pully: Return/tail pullys are used to redirect the conveyor belt back to the drive pully.Conveyor tail pullys can have internal bearings or be mounted on external bearings,usually located at the end of the conveyor.Conveyor tail pullys are often used as tension pullys to maintain belt tension.

- Idler: Any freely rotating pully used in a non-drive position to support the belt.

- Short Pully: A type of conveyor belt pully used to increase the tension of the belt wrapped around the drive pully,usually to increase belt traction.

- Tension Pully: A conveyor belt pully that can be adjusted in a bracket to increase or decrease belt slack or belt tension.

- Bend Pully: A conveyor belt pully used to change the direction of the conveyor belt and provide belt tension when bending in the conveyor system.

- Conveyor Belt Pully: A roller assembly used in the conveyor to support the transported product.These rollers are also used in the return section below the conveyor as support for the return part of the conveyor belt.

- Surface-Enhanced Pully: It is particularly suitable for pullys where slipping and severe wear problems cause typical rubber lagging layers to fail.Aluminum oxide ceramic tiles provide the best grip for the belt under muddy,rainy,or other challenging conditions.