Conveyor Impact Idlers are one of the commonly used components in belt conveyor systems. Their primary function is to absorb the impact caused by material falling from chutes or loading points, preventing damage or deterioration of the conveyor belt and ensuring the smooth operation of the entire system. The Impact Idlers produced by Zoomry Heavy Industry are made from high-wear, shock-resistant rubber materials, which are vulcanized to bond securely with steel tubes, ensuring excellent bonding strength between the rubber rings and the idlers. Impact Idlers are widely used in environments with high shock loads, particularly at material drop-off points and transfer points. By effectively absorbing the impact force, they reduce the shock to the conveyor belt, thereby extending the life of the belt, decreasing the failure rate of equipment, and improving production efficiency.

■ Application Scenarios

Impact Idlers are mainly used at the receiving points of belt conveyors, particularly in industries such as coal mining, power generation, fertilizers, steel, and chemicals, where materials fall from heights or slide into the belt from chutes, resulting in significant impact forces. Installing Impact Idlers at these points can effectively reduce the impact on the conveyor belt and prevent damage. In environments such as coal mines, washing plants, and coke plants, where corrosion is a concern, the corrosion resistance of Impact Idlers is particularly important, significantly extending their service life.

● Coal Mines and Washing Plants: Large particles of material falling can cause significant impact to the conveyor belt. Using Impact Idlers can effectively reduce the impact and extend the belt’s lifespan.

● Coke Plants: Due to the high temperature and corrosive nature of the materials, the corrosion and high-temperature resistance of Impact Idlers is crucial.

● Chemical Plants: The granular materials in chemical production can cause wear and tear on equipment. Impact Idlers effectively absorb the shock and ensure stable operation of the equipment.

● Power and Steel Industries: With rapid material transport and high-load operation, Impact Idlers can significantly reduce equipment failures and maintenance costs.

■ Features

● Excellent Impact Resistance: Zoomry’s Impact Idlers are made from high-wear rubber materials, providing excellent impact resistance. They effectively reduce the shock to the conveyor belt, preventing damage to the belt conveyor system.

● Strong Corrosion Resistance: Especially suitable for chemical or highly corrosive environments, Zoomry Impact Idlers are made with high-quality materials and surface treatment technologies to ensure long service life in harsh conditions.

● High Wear Resistance: The rubber rings are made using a special manufacturing process, enabling them to withstand frequent material impacts and wear, extending the service life of the Impact Idlers.

● Strong Load Capacity: By using thickened steel tubes and high-quality steel, Impact Idlers have a strong load-bearing capacity, making them suitable for high-load and harsh operational conditions.

● Easy Maintenance: The design of Impact Idlers is simple and easy to maintain and replace, reducing downtime and maintenance costs.

■ Product Types

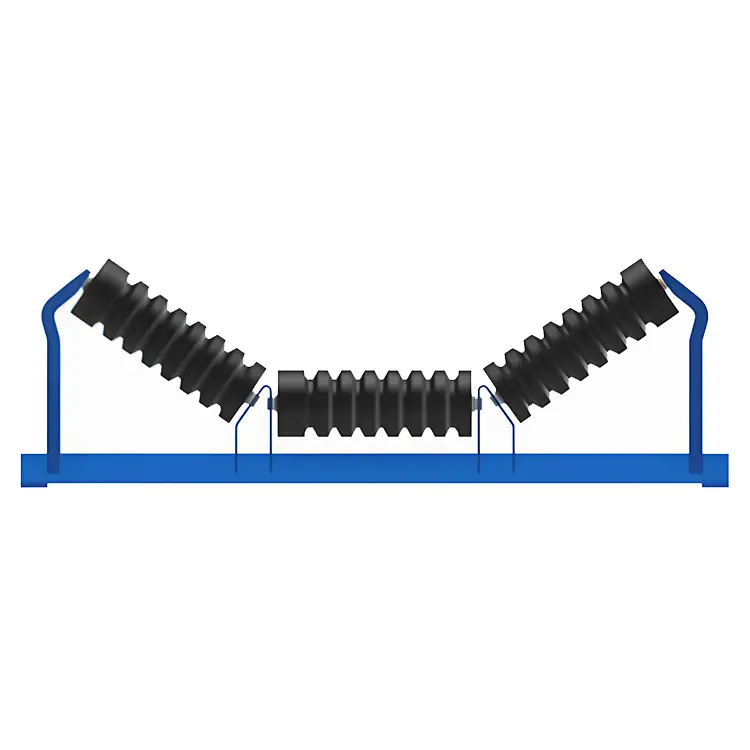

● Troughing Impact Idler

Troughing Impact Idlers are the most common type of Impact Idlers and are used in trough-shaped belt conveyors. Typically, three Impact Idlers are used to effectively distribute the shock load and protect the conveyor belt from damage.

● Flat Impact Idler

Flat Impact Idlers are used in flat belt conveyors and typically feature one Impact Idler. They provide effective shock absorption for flat belt systems, ensuring smooth belt operation.

● Offset Troughing Impact Idler

The middle Impact Idler of an Offset Troughing Impact Idler is not aligned with the others. This design is suitable for more complex conveyor configurations and better distributes the impact force, preventing the concentration of shock at one location.

● Garland Impact Idler

Garland Impact Idlers are suspended from the conveyor frame and usually feature two Impact Idlers. They are suitable for special conveyor systems and effectively reduce impact while improving system stability.

■ Product Parameters

| Specification of Conveyor Impacty Idlers |

| Carrying Idler Type | Belt Width (mm) |

| V-type Impact Idler (2 rollers) | 300 - 800 |

| Carrying Impact Idler (3 rollers) | 400 - 2200 |

| Carrying Impact Idler (1 roller) | 300 - 2000 |

| Standard | DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc. |