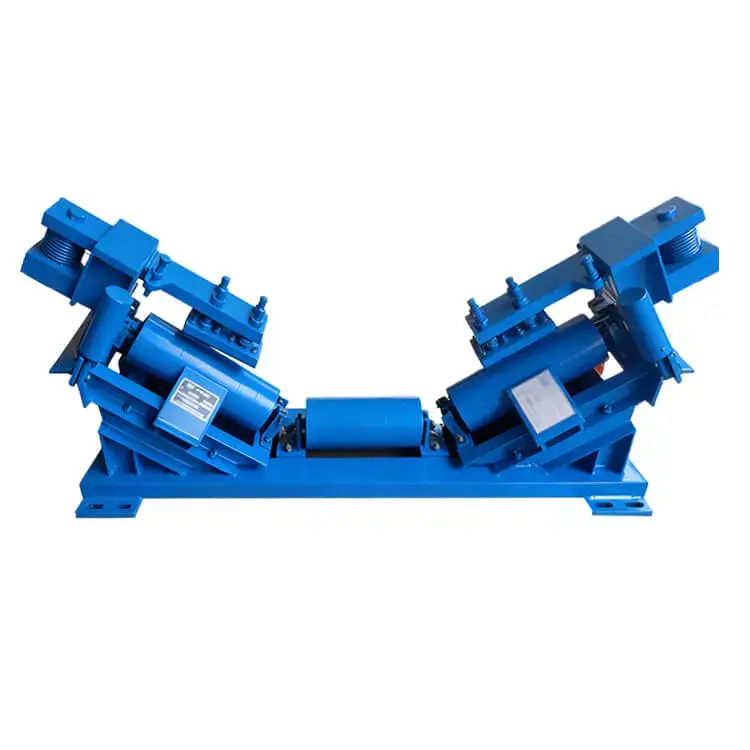

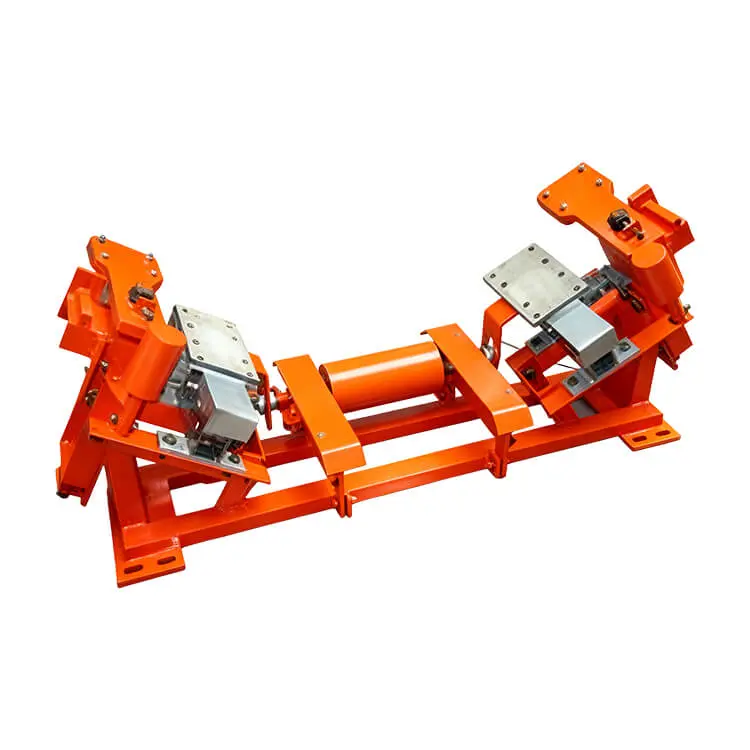

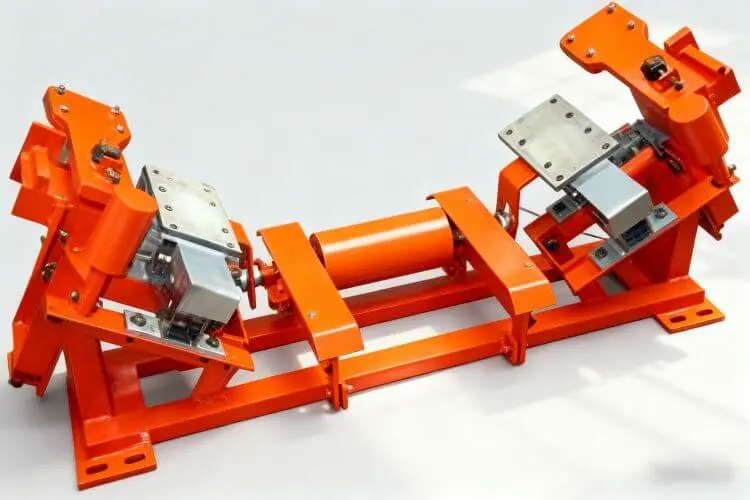

ZOOMRY Belt Broken Protective Device is an intelligent safety equipment that integrates "monitoring-triggering-braking-locking" in one, with core functions covering key needs such as belt break arrest, belt fracture protection, and conveyor safety guarantee. Breaking the traditional single protection mode, the product realizes rapid response and effective control of belt conveyor belt break accidents through the coordinated operation of mechanical and hydraulic systems. It adapts to an inclination angle range of -25° to +32°, is compatible with different working conditions such as light load, medium load, and heavy load, and can be accurately matched with belt conveyors of various bandwidths from 650mm to 2200mm. It provides international standard safety protection support for bulk material conveying systems in industries such as mining, ports, power plants, building materials, and chemical engineering.

As a core safety accessory for bulk material conveying equipment, ZOOMRY Belt Broken Protective Device maintains stable performance in harsh environments such as extreme temperatures (-40℃~+60℃), complex inclination angles, and high-load operation through optimized structural design and material selection. It fundamentally solves the problem of belt break protection for long-distance, large-inclination, and heavy-load conveyors, helping enterprises improve safety production levels and reduce accident rates and operation and maintenance costs.

Core Technical Advantages of Belt Broken Protective Device

Millisecond-level Response Speed

ZOOMRY Belt Broken Protective Device innovatively adopts a "mechanical + hydraulic" dual-trigger mechanism, combined with gravity-driven auxiliary design, to achieve rapid identification and braking of belt break accidents. When the belt breaks, the mechanical structure first captures the belt slack signal, synchronously triggers the hydraulic system to increase pressure, and drives the arrest mechanism to clamp the belt within milliseconds. The braking deceleration is controlled between 0.2-0.5m/s², avoiding secondary damage to the belt or material splashing caused by excessive braking.

Compared with traditional single mechanical trigger equipment, the dual-trigger system not only retains the reliability of the mechanical structure but also exerts the stability of the hydraulic system. It automatically adjusts the braking force according to different working conditions (upward conveying, downward conveying, horizontal conveying), ensuring accurate arrest and stable braking within the wide inclination angle range of -25° to +32°, regardless of whether the belt is empty, fully loaded, or overloaded.

Full-belt Bidirectional Arrest

The Belt Broken Protective Device adopts a full-belt bidirectional arrest design, which can simultaneously respond to multiple risks such as upward belt breakage, downward belt breakage, and belt deviation. The arrest mechanism is made of high-strength wear-resistant materials, with a large contact area with the belt and uniform pressure distribution. During the arrest process, it can not only firmly lock the belt but also avoid scratching the belt surface, extending the service life of the belt.

The application of bidirectional arrest technology enables the equipment to be universally used for both upward and downward conveying conveyors without distinguishing the operation direction of the conveyor, greatly reducing the equipment procurement and installation costs of enterprises. At the same time, the opening and reset of the arrest mechanism adopt automatic design, which can quickly resume production after the accident is handled, reducing downtime.

Coverage of Multiple Series and Models

Based on the differentiated needs of different industries and working conditions, ZOOMRY has developed three major series of Belt Broken Protective Devices: light-load type, general-purpose type, and heavy-load type. With rated braking force ranging from 50kN to 1500kN and applicable bandwidth from 650mm to 2200mm, it fully covers the protection needs of various belt conveyors:

- Light-load Type: Suitable for medium and short-distance conveyors with bandwidth 650-1200mm and belt strength 800-1800N/mm. Adopting pure mechanical + gravity drive, it has flexible installation spacing (30-80m for upward conveying / 80-150m for downward conveying) and adapts to an inclination angle of -15°~+20°, meeting the light-load bulk material conveying protection needs of food, light industry and other industries;

- General-purpose Type: Rated braking force 300-600kN, suitable for conveyors with bandwidth 800-1800mm and belt strength 1200-3000N/mm. Mechanical + hydraulic auxiliary triggering, installation spacing 20-60m (upward conveying) / 50-120m (downward conveying), applicable inclination angle -20°~+28°, widely used in medium-load conveying systems in building materials, chemical, port and other industries;

- Heavy-load Type: Designed for heavy-load scenarios such as mining and power plants, with rated braking force 800-1500kN. Suitable for large conveyors with bandwidth 1400-2200mm and belt strength 1800-4000N/mm. Mechanical + hydraulic auxiliary triggering ensures high-intensity braking, installation spacing 10-30m (upward conveying) / 30-80m (downward conveying), which can cope with belt break protection for large-inclination, long-distance and heavy-load conveying of -25°~+32°.

Stable and Durable Structure

The frame of the Belt Broken Protective Device is welded with high-strength steel, undergoing strict stress testing and anti-corrosion treatment, and can withstand long-term heavy loads and erosion of harsh environments. The working temperature range covers -40℃~+60℃, whether it is mining conveying in alpine regions or coal-fired conveying in power plants under high-temperature environments, it can maintain stable performance.

Two installation methods are available for the frame: fixed type and hanging type (the heavy-load type is fixed type), which can be flexibly adjusted according to the installation space and structure type of the conveyor. The installation process is simple and convenient, without the need for large-scale transformation of the original conveyor. At the same time, the core components of the equipment adopt modular design, which is easy to maintain and has a low failure rate, greatly reducing the operation and maintenance costs of enterprises.

Application Scenarios

Core Application Industries

- Mining Industry: Suitable for long-distance, large-inclination conveyors in coal mines, metal mines, and non-metallic mines. For different operating environments such as underground and open-pit, it provides customized protection solutions with explosion-proof, dust-proof, and moisture-resistant features, ensuring the safety and stability of ore conveying processes;

- Ports and Terminals: Used for conveyors supporting Bulk Cargo Ship Loaders and ship unloaders, coping with the high humidity and high salt spray environment of marine climate, and preventing problems such as bulk cargo dumping and terminal operation interruption caused by belt breakage;

- Power Industry: Suitable for coal-fired conveying, desulfurized gypsum conveying and other systems in power plants. For working conditions with high temperature and high dust, it optimizes heat dissipation and dust-proof design to ensure 24-hour continuous and safe operation of the conveyor;

- Building Materials Industry: Used for conveying lines of cement, sand and gravel, aggregates and other materials, coping with high-wear and high-load operation needs, and reducing the impact of belt break accidents on the production process;

- Chemical Industry: For corrosive material conveying scenarios, it adopts corrosion-resistant materials and sealing design to ensure the service life and protection performance of the equipment in acid-base environments.

ZOOMRY Quality Assurance

Strict Quality Control

- Raw Material Procurement: Selects steel, hydraulic components, and mechanical accessories from internationally renowned brands. All raw materials undergo material inspection and performance testing to ensure compliance with design requirements;

- Production and Manufacturing: Adopts advanced production processes such as CNC machining centers and automatic welding equipment. Key processes implement full-process quality traceability. Each equipment undergoes multiple rounds of inspections including static testing, dynamic simulation testing, and extreme condition testing;

- Product Certification: Has passed multiple domestic and foreign authoritative certifications such as ISO9001 quality management system certification, CE certification, and mining product safety mark certification, with technical indicators reaching the international advanced level.

Professional Technology R&D

ZOOMRY has a R&D team composed of experts in mechanical design, hydraulic control, automation and other fields, focusing on technological innovation and upgrading of bulk material conveying safety equipment. The team has established cooperative relationships with many universities and research institutions at home and abroad, tracks the development trend of industry technology, continuously optimizes product structure and performance, and has obtained a number of patented technologies successively. It ensures that the product maintains leading advantages in trigger response speed, arrest stability, adaptation range and other aspects.

Comprehensive Service Support

- Customized Solutions: Provides one-on-one customized design solutions according to parameters such as the bandwidth, belt strength, inclination angle, load, and working environment of the customer's conveyor to ensure accurate adaptation of the product;

- Installation Guidance: Dispatches professional technical personnel to provide on-site installation guidance and commissioning services to assist customers in quickly completing equipment installation and acceptance;

- Technical Training: Provides technical training for customers on equipment operation, maintenance, fault diagnosis, etc., to ensure that operators proficiently master the equipment usage methods;

- After-sales Response: Establishes a global after-sales response system, provides 7×24-hour technical consultation services, and quickly solves problems encountered by customers in the process of equipment use.

Choose ZOOMRY Belt Broken Protective Device

- Advanced Technology: Mechanical + hydraulic dual-trigger technology, faster response speed and more stable arrest, wide adaptation to inclination angle, bandwidth, and load range, meeting the precise protection needs of different scenarios;

- Reliable Quality: Produced in strict accordance with international standards, undergone multiple rounds of extreme testing, can still maintain stable performance under extreme working conditions, with long service life and low operation and maintenance costs;

- Global Adaptation: The product complies with international certification standards such as ISO and CE, adapts to safety norms and industry requirements in different regions around the world, and provides consistent high-quality products and services for domestic and foreign customers.