ZOOMRY Belt Break Detection (also known as Belt Arrestor, Belt Break Safety Device, Full-Belt Break Arrestor) is a core protective equipment specially designed for Conveyor Belt Systems. With a rated braking force ranging from 50 to 1500kN and compatibility with full-specification bandwidths of 650-2200mm, it can achieve millisecond-level braking at the moment of belt breakage or severe slipping. It provides customers worldwide in mining, ports, power, building materials and other industries with belt breakage protection solutions that meet international safety standards.

Safety Guarantee Against Chain Accidents Caused by Belt Breakage

In bulk material conveying scenarios, although the incidence of belt breakage accidents is low, belt conveyors are long-term exposed to multiple issues such as material impact, belt aging, overload operation, and excessive inclination angle. Once an accident occurs, the consequences are extremely destructive. For high-inclination mining conveying lines, belt breakage may cause tens of tons of ore and coal to slide down at high speed, damaging components such as idler sets, rollers, and chutes, and even triggering roadway collapse; on belt conveyors supporting port mobile ship loaders, belt breakage will result in materials falling into the ocean or terminals, causing environmental pollution and suspension of ship operations; while a belt breakage accident in the coal conveying system of a power plant will directly lead to boiler feed interruption, resulting in millions of economic losses and large-scale power outages.

Traditional protective equipment generally has problems such as delayed response, incomplete arrest, and easy belt damage, which are difficult to meet the core needs of global customers for high reliability and full-scenario adaptation. With years of experience in the bulk material conveying equipment field, ZOOMRY has developed a series of Belt Break Detection products covering light to heavy loads based on in-depth research on different working conditions around the world. The equipment can seamlessly cooperate with ZOOMRY's Conveyor Rollers, Belt Cleaners and other components to form a complete set of solutions, completely solving the chain crisis caused by belt breakage accidents. It provides domestic and foreign customers with a protective choice featuring "sufficient safety redundancy, international standard adaptation, and controllable operation and maintenance costs".

Triple Protection Technology

Dual-Mode Triggering for Comprehensive Response

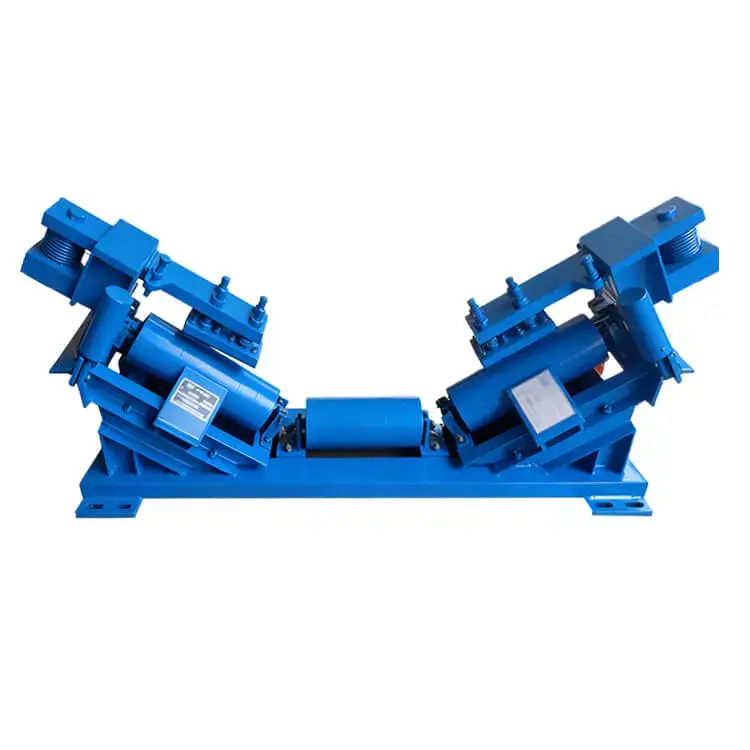

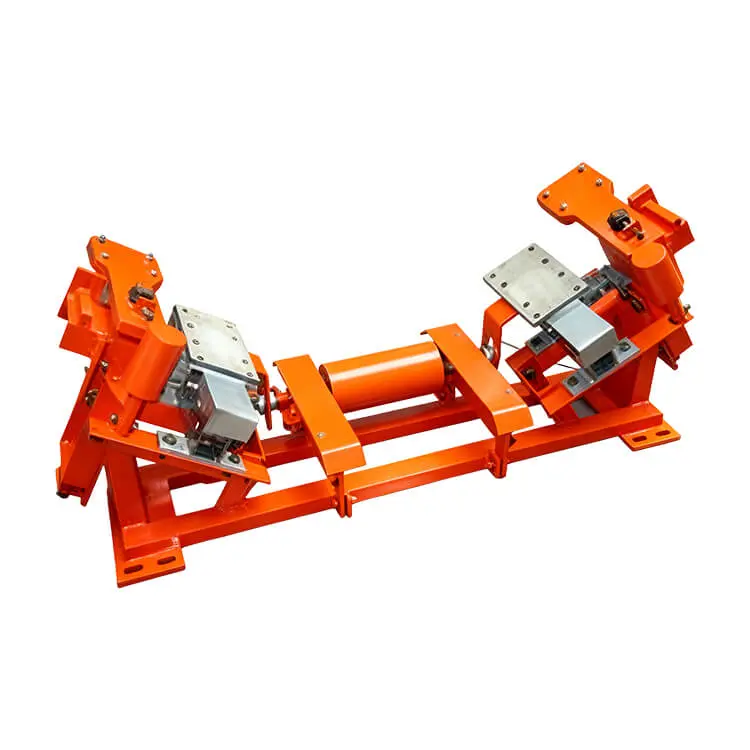

ZOOMRY Belt Break Detection adopts a dual-trigger mode of "pure mechanical + gravity-driven" and "mechanical + hydraulic-assisted" to adapt to different load and scenario requirements. The light-load type (rated braking force 50-200kN) relies on a pure mechanical gravity-driven mechanism, without the need for external power supply, hydraulic stations or other auxiliary equipment. It is completely triggered by sudden changes in belt tension and gravity sensing. Even in power-free underground mine environments, extreme cold climates of -40℃, or high-humidity and salt-spray port scenarios, it can avoid failures caused by electromagnetic interference or power interruption, with a stable response time within 0.3 seconds.

The general-purpose type (300-600kN) and heavy-load type (800-1500kN) are equipped with hydraulic-assisted triggering technology, combined with high-precision tension sensors and speed monitoring modules. They can real-time capture abnormal signals such as sudden drop in belt tension and overspeed slipping, realizing a fully automated process. The response speed is increased to 0.2-0.3 seconds, perfectly adapting to heavy-load scenarios with large conveying capacity and high belt speed (4-6m/s), ensuring that belt breakage risks are quickly captured as soon as they appear.

Full-Belt Locking Without Secondary Damage

Different from the "point-contact braking" of traditional single-side arrest equipment, ZOOMRY Belt Break Detection adopts a symmetrical wedge-shaped brake block structure to achieve full-belt bidirectional arrest. After triggering, the brake blocks on both sides synchronously tighten towards the center of the belt, not only firmly locking the load-bearing section of the belt (to prevent material rollover and falling) but also accurately fixing the return section of the belt (to avoid belt stacking and winding around the roller). The arrest coverage rate reaches 100%, completely eliminating the protection loophole of "one-side slip".

The brake surface material is made of REACH-compliant polyurethane and rubber composite formula, which has undergone special wear-resistant treatment. The anti-slip coefficient is ≥0.8, which can not only ensure sufficient braking friction but also avoid secondary damage such as scratches and tears to the belt surface, extending the service life of the conveyor belt. At the same time, the braking deceleration is strictly controlled at 0.2-0.5m/s², and the inertial impact force is absorbed through the built-in buffer mechanism, avoiding equipment resonance or structural deformation caused by excessive braking force, and balancing safety and equipment protection.

High-Strength Structure for Full-Environment Adaptation

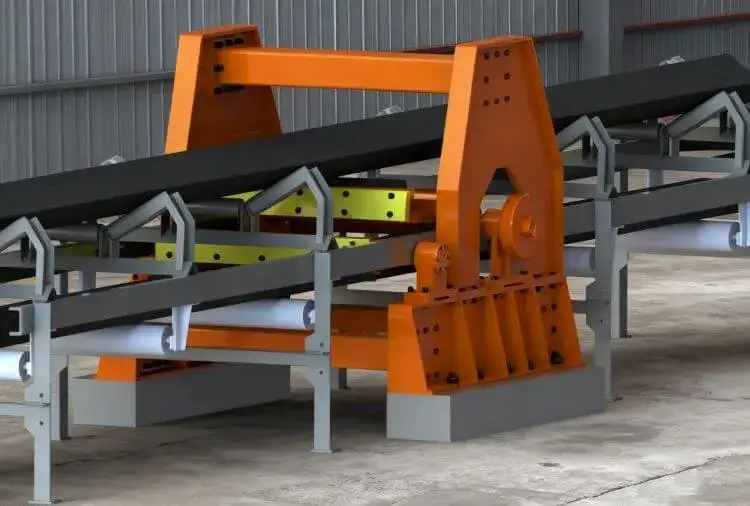

The product frame is integrally formed with Q235B/Q355B high-strength section steel and alloy steel, and has passed ultrasonic flaw detection. The defect grade meets the JB/T4730.3 Level I standard, which can withstand the instantaneous impact force (up to 1500kN) during heavy-load arrest. Two types of frames are available: fixed type and hanging type. The light-load type and general-purpose type support quick-installation fixture installation, without the need for fire work or drilling, and a single set can be deployed within 2 hours, which can be easily adapted to existing belt conveyors; the heavy-load type adopts bolt fixing + foundation reinforcement design to ensure installation stability in high-inclination (-25°~+32°) and large-conveying-capacity scenarios.

In terms of environmental adaptation, the product's protection level reaches IP65-IP67, and the corrosion resistance level meets the ISO 12944-6 C4-C5-M standard. Key components are subjected to double treatment of galvanizing + spray coating, which can resist erosion from harsh environments such as mine dust, port salt spray, and corrosive gases in building materials factories. The working temperature ranges from -40℃ to +60℃, adapting to the operation needs of different climate regions around the world such as frigid zones, tropical zones, and coastal areas.

Core Advantages of ZOOMRY Belt Break Detection

- Comprehensive Coverage of International Standards: The product strictly follows core standards such as China's NB/T 11464-2023, EU's EN 12895, North America's ASTM D3794, and international ISO 5048. It has obtained multiple authoritative certifications including CE, ATEX explosion-proof certification (for explosive environments), and MA coal mine safety mark certification. It fully meets the access requirements of major global markets such as Europe, North America, and Southeast Asia, and no additional adaptation or modification is required for export.

- Strong Main Engine Coordination: As a core supporting component of ZOOMRY's bulk material conveying complete sets of equipment, the Belt Break Detection adopts a standardized size interface design with ZOOMRY's own main engine products such as Belt Conveyors, Telescopic Stackers, and Truck Unloaders, and can be quickly matched without additional modification. It is also compatible with other international brand conveyors, with full-range parameter coverage of rated braking force 50-1500kN, bandwidth 650-2200mm, and belt strength 800-4000N/mm. Whether it is a light-load grain depot conveying line or a heavy-load mine inclined shaft belt conveyor, it can be accurately matched.

- Sufficient Safety Redundancy: The dual-mode triggering mechanism solves the reliability problem in extreme environments. The full-belt bidirectional arrest design eliminates protection blind spots. The rated braking force reserves 20%-30% safety redundancy. Verified by mechanical simulation, even in extreme working conditions exceeding 1.5 times the design load, it can still achieve stable arrest. The installation spacing can be dynamically adjusted according to the inclination angle (10-80m for upward conveying / 30-150m for downward conveying), ensuring no protection blind spots when a belt breakage accident occurs, and providing customers with "double insurance".

- Low-Cost Operation and Maintenance: Wearing parts such as brake surface blocks and trigger springs adopt a modular and standardized design, sharing the supply chain with ZOOMRY's existing components such as idlers and belt cleaners. They have strong versatility, and customers can quickly purchase and replace them through regional distributors and online procurement platforms without separately reserving special spare parts. The product design life is ≥10 years, requiring only regular appearance inspection and brake block wear detection. The low-frequency maintenance demand greatly reduces long-term operation costs, saving 15%-20% compared with similar imported products.

Adaptable Application Scenarios

Mining Industry

Underground mine inclined shaft conveying lines and open-pit mine belt conveyor systems generally have the characteristics of large inclination angles (15°-32°), heavy materials, high dust, and humid environments. The belt is severely impacted and worn, with a high risk of belt breakage. ZOOMRY's heavy-load Belt Break Detection (800-1500kN) can quickly lock the belt at the moment of breakage by virtue of mechanical + hydraulic dual-trigger technology, avoiding tens of tons of iron ore and coal from falling and damaging equipment or causing collapse accidents. To meet the explosion-proof requirements of underground coal mines, the product has passed ATEX and MA certifications, with a protection level of IP67, which can adapt to high-dust and power-free environments. It works in coordination with ZOOMRY's own belt conveyors and scrapers to ensure 24-hour continuous mine production and reduce accident downtime losses.

Port Industry

Belt conveyors supporting mobile ship loaders and telescopic stackers in port bulk terminals have the characteristics of large bandwidth (1400-2200mm), high belt speed (4-6m/s), and complex operating environments (salt spray, humidity). Belt breakage accidents will not only cause material losses and environmental pollution but also affect ship berthing efficiency. ZOOMRY's general-purpose and heavy-load Belt Break Detection adopt anti-corrosion coatings and IP65+ protection design, which can resist salt spray erosion. The full-belt bidirectional arrest design can avoid the stacking and winding of high-speed running belts around rollers. It is linked with the port automatic control system to realize fault alarm and emergency shutdown linkage, ensuring the safe transportation of bulk materials such as coal and ore, and adapting to the large-scale and high-speed conveying needs of ports.

Power Industry

The coal conveying system of thermal power plants and nuclear power plants is the "lifeline" of energy supply. Belt conveyors need to operate continuously for 24 hours, conveying energy materials such as coal and biomass fuel. A belt breakage accident will directly lead to power generation interruption. ZOOMRY's general-purpose Belt Break Detection (300-600kN) is suitable for medium and low inclination (-15°~+20°) working conditions of power plants. The pure mechanical + gravity-driven mode does not rely on external power supply, avoiding protection failure during power outages. The product is linked with the power plant's PLC control system. When triggered, it synchronously cuts off the power supply and sends a remote alarm, facilitating operation and maintenance personnel to quickly handle and reduce downtime, ensuring stable power supply. It has become an "indispensable safety redundancy" for the power plant's coal conveying system.

Building Materials Industry

Aggregate conveying lines and cement clinker conveying systems in cement plants and mixing stations convey materials including sand and gravel aggregates, cement clinker, fly ash, etc. Some materials are corrosive or highly abrasive, requiring high adaptability of protective equipment. ZOOMRY's light-load and general-purpose Belt Break Detection (50-600kN) can be flexibly adapted according to material characteristics. Anti-corrosion materials are used for corrosive material scenarios, and alloy + rubber composite brake surfaces are selected for highly abrasive material scenarios to extend service life. The product is used with ZOOMRY's own hopper feeders and truck unloaders, suitable for belt conveyors with a bandwidth of 650-1800mm, ensuring the continuous safety of the building materials production process and avoiding production line stagnation caused by belt breakage accidents.

Selection Guide for Belt Break Detection

Selection by Working Condition Intensity

- Light-load working conditions (rated braking force 50-200kN): Suitable for scenarios with bandwidth 650-1200mm and inclination angle -15°~+20°, such as closed belt conveyors in grain depots and small industrial conveying lines. The conveyed materials are grain, light building materials, etc. The pure mechanical + gravity-driven mode is preferred for low cost and easy maintenance.

- General working conditions (rated braking force 300-600kN): Suitable for scenarios with bandwidth 800-1800mm and inclination angle -20°~+28°, such as power plant coal conveying lines and port medium-speed belt conveyors. The conveyed materials are coal, sand and gravel aggregates, etc. The mechanical + hydraulic-assisted triggering mode balances response speed and reliability.

- Heavy-load working conditions (rated braking force 800-1500kN): Suitable for scenarios with bandwidth 1400-2200mm and inclination angle -25°~+32°, such as high-inclination mining conveying lines and port high-speed ship loaders. The conveyed materials are iron ore, heavy ore, etc. The hydraulic-assisted triggering + fixed frame design ensures stable arrest.

Selection by Environmental Conditions

- Explosive scenarios (underground coal mines, chemical workshops): Select models with ATEX or MA certification, with protection level ≥IP67, to avoid safety hazards caused by electrical components.

- Corrosive environments (ports, coastal areas, chemical parks): Select models with corrosion resistance grade C5-M. Core components are subjected to double treatment of galvanizing + spray coating to resist salt spray and corrosive gases.

- Extreme temperatures (frigid zones, tropical zones): No additional modification is required. The product's working temperature covers -40℃~+60℃. For frigid zone scenarios, pure mechanical drive is preferred (to avoid hydraulic oil solidification), and heat dissipation structures can be matched for tropical zone scenarios.

Selection by Supporting Requirements

- Matching with ZOOMRY's own main engine: Directly select the corresponding adapted model. For example, the models supporting belt conveyors and bucket wheel stacker-reclaimers have preset installation interfaces, requiring no additional adjustments.

- Matching with other brand main engines: Provide parameters such as belt conveyor bandwidth, inclination angle, belt strength, and installation space. ZOOMRY engineers will provide customized adaptation schemes to ensure installation compatibility.

- Remote operation and maintenance requirements: Select models with intelligent diagnosis functions that can real-time monitor brake block wear and tension abnormalities, supporting remote alarm and fault diagnosis, and adapting to unattended scenarios.

Global Quality Assurance

International Compliance

The product fully complies with domestic and foreign core standards such as EU's EN 12895, North America's ASTM D3794, and China's NB/T 11464-2023. It has passed multiple authoritative certifications including CE, ATEX, and MA. Among them, REACH compliance ensures that the product materials do not contain EU Substances of Very High Concern (SVHC), and RoHS compliance meets the environmental requirements of electrical and electronic equipment. It is fully adapted to the market access rules of different regions around the world, and no additional rectification is required for export.

Quality Control

ZOOMRY has established a production control process in line with the ISO 9001 quality system. Core components (frame, brake block, trigger mechanism) are made of high-quality materials, and undergo multiple inspection processes such as ultrasonic flaw detection, dynamic load testing, and high and low temperature environment testing. Before leaving the factory, the product undergoes simulated belt breakage testing. Key indicators such as arrest response time, braking distance, and locking reliability are recorded, and a complete test report can be provided to customers to ensure the performance of each product meets the standards.

Technical Precipitation

With years of experience in the bulk material conveying equipment field, ZOOMRY has accumulated application experience in thousands of projects around the world. The engineer team is familiar with the industry standards and working condition characteristics of different regions, and can provide customers with full-process technical support from selection, design to installation. Product technology iteration is based on real working condition feedback. For example, the hydraulic triggering mechanism optimized for high-inclination mining scenarios and the anti-corrosion coating upgraded for port salt spray environments are all derived from practical experience, demonstrating professional strength.

After-Sales Service

Unobstructed Rapid Supply

Wearing parts such as brake surface blocks, trigger springs, and seals adopt a standardized design, sharing the supply chain with ZOOMRY's existing components. Customers can quickly purchase them through regional distributors and online procurement platforms, and rely on the global logistics network to achieve efficient delivery without long waiting for special spare parts.

Full-Cycle Technical Support

A 7×24 global technical consultation hotline is provided. Whether customers are located in China or overseas, they can obtain services such as fault diagnosis and technical guidance at any time. For large-scale projects, technical engineers can be dispatched to provide on-site installation guidance and commissioning training services to ensure the product is quickly put into use; at the same time, product maintenance manuals and other materials are regularly released to help customers improve equipment operation and maintenance capabilities.

Quality Assurance and Lifelong Maintenance

The product provides graded quality assurance services (2 years for light-load type, 3 years for general-purpose type, 5 years for heavy-load type). For product failures caused by non-human factors during the warranty period, free repair or replacement services are provided. After the warranty period, lifelong maintenance services are provided, with reasonable component costs charged. At the same time, customer equipment files are established to regularly remind maintenance nodes, ensuring long-term stable operation of the equipment.