Zoomry Heavy Industry's Curved Belt Conveyor (also known as Radius Conveyor/Turning Conveyor Equipment) serves as core equipment in modern industrial conveying systems, employing three-dimensional spatial turning technology to achieve damage-free material transfer. This system accommodates various turning angles including 90° and 180°, with complementary roller conveyor systems and sorting devices forming intelligent conveying solutions widely applied across 12 industries including food processing, automotive manufacturing, and biopharmaceuticals.

Technical Parameter System

Basic Specifications

| Parameter | Standard Range | Customization Capability |

|---|

| Belt Width | 500-2400mm | Max 3000mm |

| Speed Range | 0.8-6.5m/s | Adjustable VFD Control |

| Maximum capacity | 17,000t/h | Modular Enhancement |

| Turning Angle | 30°-180° | 3D Compound Turning |

| Temperature | -25℃ to +120℃ | Special Material Solutions |

| Max Single Length | Standard 70m | EPC Projects up to 70km |

Safety Monitoring System

- Misalignment Detection: Dual-channel laser scanning with auto-correction at >5% deviation

- Emergency Stop Cord: IP67 rating, <0.5s response, bidirectional trigger

- Zero Speed Protector: HENGSTLER encoder with ±0.01rpm precision

Engineering Configuration

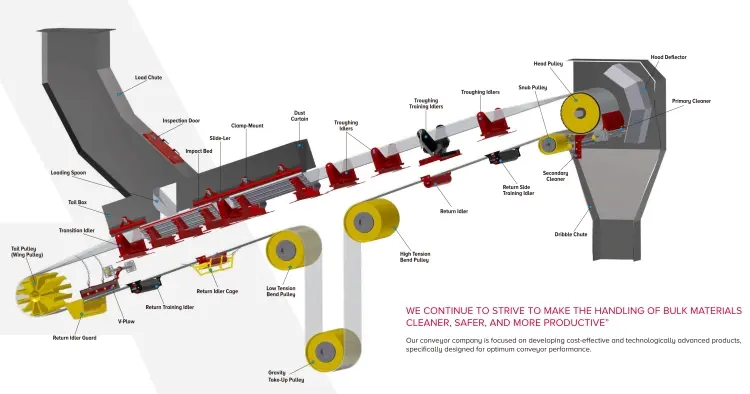

Core Components

- Turning Drive Unit: Triple-motor vector control (5.5-315kW)

- Special Belting: Anti-static/Food-grade/High-temperature (≤400℃) options

- Truss Structure: Q355B steel with modular flange connections

Smart Options

- 5G Remote Maintenance Interface

- Dynamic Material Flow Balancing

- Predictive Maintenance Platform

Zoomry Curved Belt Conveyor Typical Applications

Mining Ore Transport

In closed-loop systems from open pits to crushing stations, the Curved Belt Conveyor continuously transports lump ores with density ≤3.2t/m³. The 35° deep-trough design with impact-resistant ceramic rollers effectively handles iron/copper ores ≤400mm. Vector VFD drives enable 22% energy recovery across 800m elevation drops, with radar scanners monitoring material flow distribution.

Port Container Handling

Automates 90° transfers of 40ft containers between quay cranes and yards. FEA-optimized steel frames withstand Category 12 typhoon winds. Laser guidance ensures ±5mm AGV docking accuracy. 316L stainless steel components resist salt corrosion for ≥20 years, with self-clearing chutes preventing shellfish accumulation.

Automotive Welding Shops

Performs 180° spatial transfers for auto body components using belts with ≤10^6Ω surface resistivity. Vision systems synchronize with KUKA robots at 0.1s intervals. Cleanroom versions with laminar hoods achieve ISO 14644-1 Class 7 standards, while explosion-proof models meet IIBT4 requirements for paint shops.

E-commerce Sorting Centers

Processes 20,000 parcels/hour with 90° directional switches for packages as small as 150×100×50mm. Curved Belt Conveyor integrated dynamic weighing (±10g) and DWS scanning ensure ≥99.97% sorting accuracy. The low-noise design maintains ≤65dB(A) per GB 3096-2008 Class II standards.

Food-Grade Material Handling

GMP-compliant systems perform 270° transfers for biscuits/chocolates using FDA-certified belts (-40℃ to +220℃). CIP cleaning and IP69K quick-release designs meet hygiene requirements, while vacuum-assisted skirts limit powder residue to ≤0.02g/m².

Cement Plant Raw Materials

8.5km single-unit systems complete 3D spatial transfers in limestone pre-homogenization yards. Dual-sealed chutes achieve ≥99.5% dust capture with JIS M4002 Grade H ceramic liners at impact zones, synchronizing with kiln preheaters for 5500t/d automated feeding.

Industry-Specific Configurations:

- Explosion-proof: ATEX/IECEx certified

- Arctic-grade: -50℃ operation package

- Smart: 5G+MEC edge computing

- Cleanroom: FFU laminar flow systems

Technical Comparison

| Parameter | Standard | Enhanced | Special |

|---|

| Max Speed | 3.15m/s | 4.5m/s | 6.3m/s |

| Min Turn Radius | 900mm | 600mm | 300mm |

| Dynamic Load | 150kg/m | 300kg/m | 800kg/m |

| Positioning | ±10mm | ±5mm | ±1mm |

| IP Rating | IP54 | IP66 | IP69K |

| Surface Resistivity | 10^9Ω | 10^6Ω | 10^3Ω |

Selection Guide:

- Standard Curved Belt Conveyor suit general industrial use

- Enhanced versions recommended for precision automation

- Hazardous environments require special explosion-proof units

- Food/pharma mandates cleanroom components

Technical Support

Field Vulcanization

- Dual-voltage (220V/380V) hot press equipment

- DIN 22101 compliant processes

- 90%+ original strength joints

Certifications

- Quality: ISO9001/14001 certified

- Global Compliance: CE, EAC, GOST

- Patents: 7 turning mechanism inventions

We deliver via EPC turnkey solutions covering design, manufacturing, and smart O&M. Our engineering team possesses 2000+ hours of multinational project experience, offering customized solutions for dustproof/explosion-proof/corrosion-resistant scenarios. Visit our official website for 3D simulation proposals.