The belt cleaner (or scraper belt) is a device used to efficiently remove bulk material from conveyor belts. It is widely used in bulk material handling industries, particularly in mining, coal mining, steel, chemical industries, and more. Residual material left on the conveyor belt, if not cleaned in time, can lead to belt misalignment, increased wear, and even affect the overall system's operational efficiency.

As an expert in conveyor components, Zoomry is dedicated to offering a wide range of belt cleaners, including primary belt cleaners, secondary belt cleaners, and return belt cleaners, to meet the requirements of different working conditions and applications. With professional design and sophisticated manufacturing processes, our products deliver excellent cleaning performance and long-lasting durability, effectively enhancing the operating efficiency of conveyor systems and reducing downtime and maintenance costs.

■ Types of Belt Cleaners

● Primary Belt Cleaner (Pre-Cleaner)

Primary belt cleaners are typically installed at the discharge end of the conveyor, near the head pulley, to remove larger material and provide an initial cleaning of the belt surface. Pre-cleaners effectively eliminate most of the material adhered to the belt, reducing material carryback and preventing excessive wear on the system. Primary belt cleaners usually use polyurethane or tungsten steel blades, which are wear-resistant and impact-resistant, ensuring efficient cleaning even in harsh environments.

● Secondary Belt Cleaner

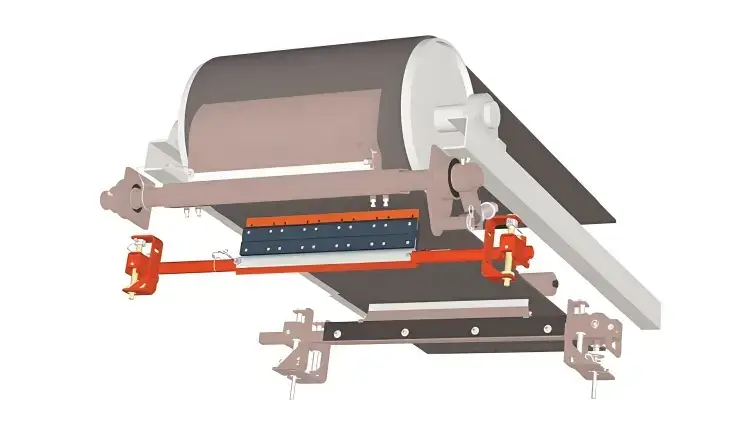

Secondary belt cleaners are installed just below the head pulley to remove smaller materials that the primary cleaner may have missed. After passing through the primary cleaner, the remaining material is typically smaller particles or sticky substances, and the secondary cleaner ensures the belt is thoroughly cleaned. Zoomry's secondary belt cleaners are made from highly wear-resistant materials, ideal for removing fine particles effectively.

● Return Belt Cleaner

Return belt cleaners are usually installed at the tail of the conveyor to clean residual material on the return side of the belt. If these materials are not removed, they can cause secondary contamination and reduce system efficiency. Zoomry's return belt cleaners are designed to ensure no residual material on the return side of the belt, making the entire conveyor system more efficient and environmentally friendly, while reducing maintenance frequency.

■ Specifications

| model | bandwidth | scraper width |

| QSY80 | 800 | 650 |

| QSY100 | 1000 | 850 |

| QSY120 | 1200 | 1050 |

| QSY140 | 1400 | 1250 |

| QSY160 | 1600 | 1450 |

| QSY180 | 1800 | 1650 |

| QSY200 | 2000 | 1850 |

| QSY220 | 2200 | 2050 |

| QSE80 | 800 | 900 |

| QSE100 | 1000 | 1050 |

| QSE120 | 1200 | 1200 |

| QSE140 | 1400 | 1500 |

| QSE160 | 1600 | 1650 |

| QSE180 | 1800 | 1800 |

| QSE200 | 2000 | 2100 |

| QSE220 | 2200 | 2250 |

| QSV80 | 800 | 1400 |

| QSV100 | 1000 | 1600 |

| QSV120 | 1200 | 1850 |

| QSV140 | 1400 | 2050 |

| QSV160 | 1600 | 2310 |

| QSV180 | 1800 | 2540 |

| QSV200 | 2000 | 2720 |

■ Advantages of Zoomry Belt Cleaners

● Automatic Tensioning Device

Zoomry belt cleaners are equipped with an automatic tensioning device that maintains the appropriate cleaning pressure, ensuring that the scraper blades remain in close contact with the belt surface for long-lasting and stable cleaning performance. The automatic pressure adjustment adapts to the belt’s expansion and contraction, eliminating the need for frequent manual adjustments, significantly reducing maintenance work, and achieving long-term, maintenance-free operation.

● Integrated Blade Design

Zoomry's belt cleaners feature an integrated blade structure, where the blades are tightly bonded to the support frame, increasing the cleaning force for higher efficiency. The integrated design not only improves the overall strength of the equipment but also reduces the risk of blade loosening or detachment.

● Multiple Material Options for Different Conditions

Depending on the working conditions, Zoomry provides various blade material options. The most common blade materials are polyurethane and tungsten steel:

- Polyurethane Blades: Made from high-quality polyurethane composite materials through a molding process, these blades have a smooth surface, low friction, excellent wear resistance, and high strength. Polyurethane blades are ideal for removing fine particles and sticky materials. Their abrasion resistance makes them particularly suitable for long-term, high-efficiency operations.

- Tungsten Steel Blades: Tungsten steel blades offer higher wear resistance and are commonly used for handling extremely hard or abrasive materials. Tungsten steel blades are available in single-piece and double-piece mounting plates. By simply adjusting the pressure, tungsten steel blades deliver excellent cleaning efficiency.

■ Structural Features of Belt Cleaners

● Carbon Steel Frame

Zoomry belt cleaner frames are made from carbon steel, providing a robust structure capable of withstanding high-intensity working environments, ensuring long service life and stable operation. Carbon steel frames are known for their high strength and corrosion resistance, making them particularly suitable for environments with moisture and corrosive materials.

● Adjustable Blade Pressure

Zoomry belt cleaners allow users to adjust the blade pressure according to actual requirements, ensuring optimal blade-to-belt contact for the best cleaning results. Regardless of the changes in the belt surface, the cleaner consistently provides stable cleaning performance.

● Easy Maintenance

Zoomry belt cleaners feature a modular design, making installation and maintenance simple and convenient. All components are designed for quick replacement and maintenance, reducing downtime and improving overall equipment efficiency.

■ video

■ Why Choose Zoomry

Zoomry belt cleaners are widely used in industries such as mining, coal mining, chemical, metallurgy, and power generation. In these industries, conveyor belts operate continuously, and significant material residues can accumulate over time. If not cleaned promptly, these residues not only increase the burden on the conveyor belt but can also cause belt misalignment, premature wear, or even lead to a complete production line shutdown.

By installing Zoomry belt cleaners, users can effectively reduce material residue on conveyor belts, lowering maintenance costs, extending the lifespan of belts and pulleys, and improving the overall efficiency of production lines. The automatic tensioning device and integrated blade design provide users with more efficient cleaning while reducing the frequency of maintenance. Whether in high-abrasion working environments or areas where material adhesion is a significant concern, Zoomry belt cleaners deliver superior performance and long-lasting durability.

■ How to Choose the Right Type of Cleaner

Different types of cleaners are suited to various working environments. Primary cleaners are ideal for handling larger materials, while secondary cleaners are used to further remove smaller particles. For cleaning the return side of the belt, return belt cleaners should be selected to ensure overall cleanliness throughout the conveyor system.

Additionally, the choice of blade material should vary based on the type of material being conveyed. If the material contains hard particles or corrosive substances, tungsten steel blades are recommended. For more standard materials, polyurethane blades offer a cost-effective and practical solution.