Time:2024-10-29 14:11:55 Number of Clicks:

As essential equipment in modern logistics and industrial production, conveyor systems are ubiquitous in our daily lives. While their working principle is quite simple—driving a conveyor belt to transport materials through rollers and conveyor rollers—the selection of components varies depending on the application environment and field. So, how should you choose the right conveyor roller? What Are the Different Conveyor Roller Types?

Flat rollers are the most common type of conveyor rollers. Their structure is relatively simple, typically made of low-carbon steel, stainless steel, or aluminum alloy. The surface is smooth, and in special environments, anti-corrosion treatments can be applied to extend their lifespan. Due to their low cost and a diameter range of 50-100 mm, they generally have a moderate load-bearing capacity and are suitable for use in packaging, light industry, and other fields for transporting packages, boxes, and various small, light items.

Inclined rollers are specially designed for transporting materials on slopes. They are commonly used to elevate or lower materials to different heights. Compared to standard horizontal rollers, they are designed with a specific incline angle, usually between 30° and 45°, which can be adjusted based on actual conditions. To effectively guide goods on the incline, they feature reinforced support frames to withstand the gravity and friction produced by materials during transport, increasing stability and preventing swaying during operation. They also utilize wear-resistant materials to prevent material sliding during transport and reduce wear on the rollers. Generally, inclined rollers have a larger diameter and thickness compared to standard rollers. They are typically used in situations requiring upward or downward transport, such as in warehouses and hoppers.

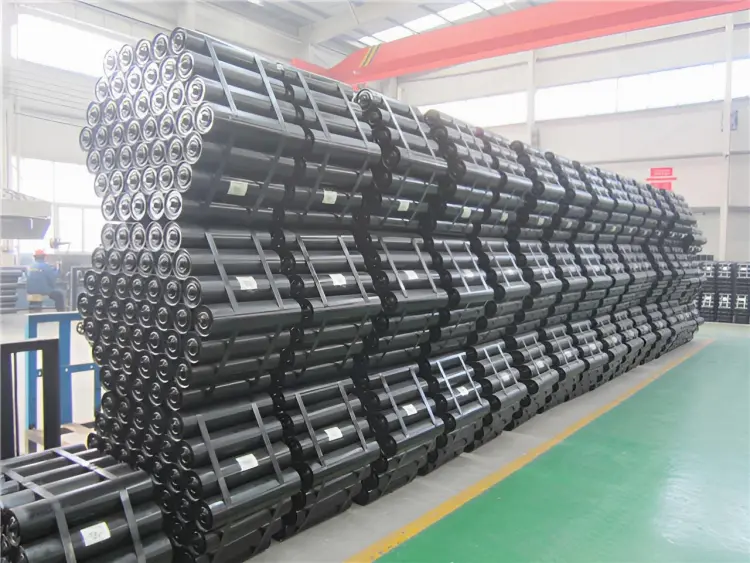

Drum rollers are specifically designed for heavy-duty items and are suitable for conveyor systems that need to support substantial weights. Their diameters typically range from 75 to 250 mm, and their design allows for load capacities of up to 500 kg or even higher. They have a larger bearing surface and stronger load-bearing capabilities, with inner cores made of high-strength alloy steel and internal rolling bearings to reduce friction and enhance operational efficiency. The surface is usually galvanized or painted to prevent corrosion, making them commonly used in mining, heavy industry, and other fields for efficiently transporting aggregates, steel, and other heavy materials.

Rubber rollers are similar to flat rollers but are coated with a rubber material 10-25 mm thick. This design is suited for high-frequency wear and provides additional friction to prevent material sliding. Some rubber rollers feature a textured surface to enhance grip and friction, making them ideal for slippery items. The elasticity of the rubber material effectively absorbs impact forces, protecting the integrity of the goods during transport. They are suitable for industries with high hygiene standards, such as food, cosmetics, and pharmaceuticals.

Additionally, there are various application-specific roller types, including self-aligning rollers, buffering rollers, trough rollers, carrying rollers, and suspended roller groups. While there are many types, they generally share similarities in material and size with the previously mentioned types. If you have any questions about conveyor roller types, please contact us using the information below:

- +86 136-6401-6717

When selecting the appropriate conveyor roller, consider the following factors:

Type of Goods: Choose the right roller based on the type of goods to be transported. For example, flat rollers are suitable for light items, while drum rollers are needed for heavy ones.

Transport Environment: The transport environment will influence roller selection. In humid or dusty environments, rubber rollers or self-cleaning rollers may be a better choice.

Load Capacity: Understanding the load capacity of the rollers is crucial. Select rollers with load capacities that meet your transport needs to avoid equipment damage.

Cost-effectiveness: Budget considerations are key when selecting conveyor rollers. Compare the cost-performance ratio of different brands and models to ensure you choose the most suitable product.

Installation Compatibility: Ensure that the rollers you purchase are compatible with your existing conveyor system, particularly regarding diameter and mounting interfaces.

Maintenance Requirements: Choose products designed for easy maintenance and replacement to reduce long-term maintenance costs.

As conveyor rollers are one of the core components of conveyor equipment, Zoomry does not recommend making hasty purchases without any preparation. This may lead to quality inconsistencies or issues with product delivery times. It is advisable to prioritize well-known brands and pay attention to their reputation and customer feedback in the industry to ensure product quality and after-sales service, maximizing your shopping and service experience. With over twenty years in the bulk material handling industry, Zoomry has significant advantages in both product quality and delivery times. If you have any questions regarding conveyor roller types, feel free to contact us for free support.

Copyright © 2002-2024 Zoomry Group Company Limited