Time:2024-10-14 16:26:38 Number of Clicks:

In modern logistics and warehouse management, an efficient cargo loading and unloading system is crucial. As a type of automated equipment, the conveyor telescopic offers flexibility and efficiency, becoming an essential tool in the field of cargo handling. Whether for truck loading or material handling on production lines, conveyor telescopics significantly improve operational efficiency. This article will explore the working principles, design, pricing factors, and applications of mobile and heavy-duty conveyor telescopics to help you understand how to choose the right equipment for different needs.

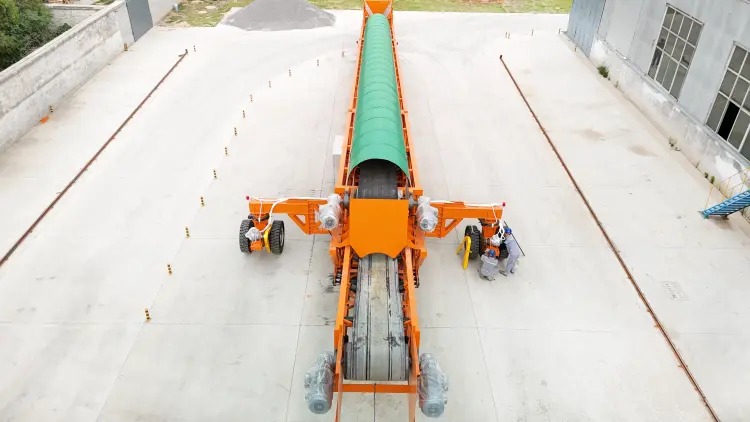

A conveyor telescopic is a conveyor system that can automatically adjust its length according to the work requirements, primarily used for cargo loading and unloading. Unlike traditional conveyors with fixed lengths, conveyor telescopics can extend or retract to adapt to different lengths of trucks, containers, or loading docks. It is designed to optimize space utilization, reduce manual labor, and increase operational efficiency.

Especially for conveyor telescopics for truck loading, they can extend directly into the truck or container, allowing automated cargo transfer, drastically reducing loading and unloading times.

The most notable feature of the conveyor telescopic is its adjustable length design. The conveyor body consists of multiple retractable sections, which can flexibly adjust its length to suit various work environments. The conveyor telescopic design utilizes advanced mechanical structures to ensure sufficient strength and stability even when fully extended.

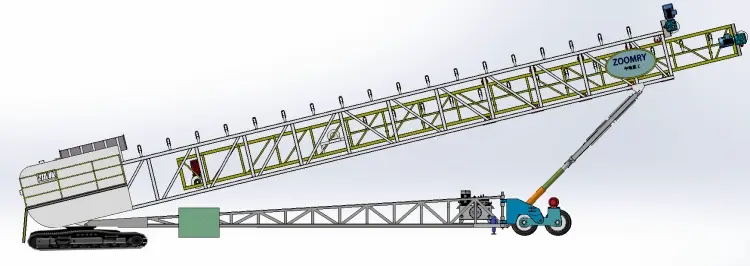

There are various types of conveyor telescopics to choose from, including fixed, mobile, and heavy-duty conveyors, each suited to different work scenarios.

Mobile Telescopic Conveyor: Designed with mobility features, allowing it to be easily moved between different loading points, ideal for warehouses and logistics centers requiring frequent cargo handling.

Heavy Duty Telescopic Conveyor: Used for handling large or heavy cargo, it is particularly suited for industrial applications where higher load capacity is required.

Modern conveyor telescopics are equipped with automated control systems, allowing operators to adjust the conveyor's length, angle, and speed through remote controls or control panels. This intelligent design not only reduces manual labor but also greatly improves operational efficiency and accuracy.

Telescopic conveyors are particularly suitable for loading and unloading trucks and containers. By extending directly into the vehicle, the conveyor can transport goods from the warehouse to the truck bed or vice versa. This automated process reduces the need for personnel to enter and exit the truck, enhancing work efficiency, especially in busy logistics centers.

In modern warehousing, fast and efficient material handling is crucial for overall logistics efficiency. Telescopic conveyors can be flexibly dispatched between multiple loading points, especially in storage locations where frequent cargo handling is required. Additionally, heavy-duty conveyor telescopics can handle large and heavy loads, making them widely used in large manufacturing plants and distribution centers.

In manufacturing, the automation of the conveyor system can significantly reduce intermediate handling steps and increase production efficiency. Telescopic conveyors not only adjust their length based on production needs but can also work with other automated equipment to handle complex material transfer tasks.

Please contact us using the info below if you have any questions about conveyor telescopic

● +86 136-6401-6717

Telescopic conveyor prices vary depending on their design, functionality, and application scenarios. The main factors affecting the price include the following:

Heavy-duty conveyor telescopics made of high-strength materials generally cost more, especially when they need to handle heavy goods, requiring the equipment’s structure to be reinforced, which increases production costs. For light-duty cargo, equipment made from standard materials will be relatively cheaper.

Telescopic conveyors with advanced automation features, such as intelligent control systems and automatic speed and length adjustments, typically cost more than traditional mechanical equipment. The higher the level of automation, the more expensive the equipment, but this also greatly enhances operational efficiency.

Depending on the specific use case, users may require customizations to their conveyor telescopics, such as adding special features, custom lengths, or higher load capacities. Customization services can increase the overall cost of the equipment but ensure that it better meets the specific needs of the operation.

If you are looking for a conveyor telescopic for sale, the following points can help you make a better decision:

When selecting a conveyor telescopic, the first consideration is your work environment and the type of goods being handled. If you need to frequently move between different loading points, a mobile conveyor telescopic is the best option. For handling large or heavy cargo, a heavy-duty conveyor telescopic is more appropriate.

Highly automated equipment can significantly boost efficiency, especially in large warehouses and logistics centers. Automation features can reduce manual handling time, minimize the risk of operational errors, and improve safety during operations.

While price is an important factor when purchasing a conveyor telescopic, after-sales service should not be overlooked. Over time, the equipment may require maintenance or parts replacement, so reliable after-sales support is crucial to ensuring the machine remains in optimal working condition.

As the demand for automation in the logistics industry continues to grow, conveyor telescopics are evolving towards greater intelligence, energy efficiency, and modularity. Future developments include:

Intelligent Control Systems: Telescopic conveyors will become smarter, with the ability to detect the type and weight of the goods and automatically adjust the speed and handling mode, improving precision and safety.

Energy-Efficient and Eco-Friendly Designs: Future conveyor systems will focus on energy optimization, using improved drive systems to reduce power consumption while meeting higher environmental standards.

Modularity: Telescopic conveyors will adopt modular designs, allowing for quick assembly and customization to suit various operational needs, enhancing flexibility and longevity.

Telescopic conveyors have become essential equipment in modern logistics, warehousing, and manufacturing, greatly improving the efficiency of cargo loading and unloading operations. Whether it’s a conveyor telescopic for truck loading or a mobile conveyor telescopic, these systems are vital for boosting productivity and reducing manual labor.

With continued technological advancements, conveyor telescopics will become more intelligent and versatile, providing superior solutions for material handling across multiple sectors. By selecting the right conveyor telescopic, businesses can improve their operational efficiency while laying a foundation for sustainable growth.

Copyright © 2002-2024 Zoomry Group Company Limited