Time:2025-08-08 11:33:52 Number of Clicks:

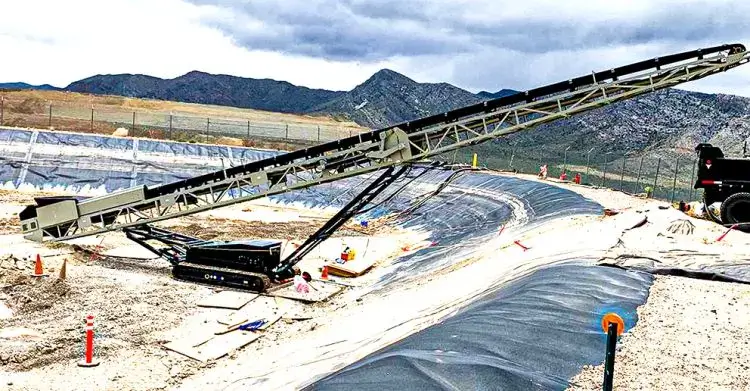

Cascading of Grasshopper Conveyors refers to connecting multiple grasshopper conveyors end-to-end to form a continuous material conveying system, so as to realize long-distance and highly flexible material transfer. The cascading design of grasshopper conveyors is commonly used in scenarios such as mines, ports, and yards. Through the collaborative work of multiple devices, the conveying efficiency is significantly improved and complex terrains are adapted to.

Generally, grasshopper conveyors adopt a wheel-type or crawler-type chassis structure. The length of a single unit can be customized to 15-40 meters, and the total length after cascading can reach hundreds of meters. The equipment is equipped with a foldable boom and a hydraulic lifting system, which can dynamically adjust the discharge height within an inclination range of ±18°, adapting to complex terrains such as mine tunnels and port terminals. It can also easily complete steering and docking in narrow areas, meeting the layout requirements in different working environments.

The cascading system is controlled by PLC + frequency converter, which real-time monitors the speed, belt tension and material flow of each conveyor. With the PID regulation algorithm, when the load of a certain device in the cascade changes suddenly, the system can complete speed matching within 0.1 seconds to avoid material accumulation. For example, using Zoomry's independently developed low-noise idlers (operating noise < 45 dB) and wear-resistant conveyor belts (service life > 150,000 hours), combined with frequency conversion speed regulation technology, the energy consumption of the cascading system can be reduced by 18%-25% compared with traditional fixed conveyors, achieving energy saving while improving operating efficiency.

The grasshopper conveyor adopts a modular pre-assembly design, with 80% of the components debugged in the factory. The on-site construction of the cascading system can be completed within 10-20 days. Key components such as the hydraulic winch system and the steel wire rope breakage protection device can automatically lock within 0.01 seconds in case of power failure or mechanical failure, ensuring system safety. Zoomry's global spare parts warehouse supports 72-hour emergency response, and with remote diagnosis function, unplanned downtime can be reduced by more than 60%, ensuring the continuous and stable operation of the system.

The working environment of mines and quarries has complex landforms such as fragmented terrain, steep slopes (slopes often reach 15°-25°), narrow tunnels (width only 3-5 meters) and soft foundations. Secondly, the material characteristics are diverse, including ores with Mohs hardness grade 7 (such as granite), viscous slag with a moisture content exceeding 20%, and bulk materials with mixed particle sizes (0.5-500mm).

The core contradiction in port and logistics scenarios lies in the "conflict between dynamic loading and unloading needs and the rigidity of fixed facilities": first, the operation areas are scattered, involving multiple nodes such as ship berths, yards, and railway lines (with distances often reaching 500-1000 meters); second, material turnover is highly frequent, requiring a single ship unloading efficiency of 2000 tons/hour, and continuous operation must be maintained during tidal changes (water level difference 3-5 meters); third, the environmental corrosion is serious, with salt spray concentration ≥ 50mg/m³ and metal corrosion rate reaching 0.1mm/year.

Zoomry's grasshopper conveyors have passed CE (Europe), EAC (Russia), KCS (South Korea) and other certifications. Key components such as idlers and drums meet CEMA (USA) standards, and can be seamlessly integrated into the existing systems of global customers. The equipment can pass various stringent tests, such as the cold resistance test (-50℃) for EAC certification, meeting the environmental and regulatory requirements of different regions and ensuring compliant use worldwide.

Zoomry's EPC+M+O full-cycle services cover the entire process from scheme design to operation and maintenance. According to different material characteristics and operation needs, exclusive conveying schemes can be customized. For example, for scenarios where large-grained ores and fine powder materials are handled simultaneously, a dual-speed and dual-material conveying scheme can be designed. Through PLC control of the belt speed and hopper inclination in different sections, interference-free conveying is realized, and system efficiency is improved.

The whole life cycle cost of Zoomry's grasshopper conveyors is 20%-30% lower than that of similar brands. Taking conventional models as an example, their purchase cost is 15% lower than that of similar European and American products, and the maintenance cost is reduced by 40% due to modular design and localized spare parts warehouses. The equipment's 5-year warranty and 2-year guarantee policy further reduce customer risks and improve product cost performance.

Zoomry's low dust emission design (dust emission < 10mg/m³) and LED intelligent lighting system make the cascading scheme meet the EU Industrial Emissions Directive (IED) requirements. At the same time, solar + diesel hybrid power can be adopted to realize partial energy self-sufficiency, reduce carbon emissions, meet increasingly strict global environmental protection standards, and help customers achieve green production.

Zoomry's remote monitoring platform can real-time collect more than 300 items of data such as equipment temperature, vibration, and energy consumption, and predict potential faults through AI algorithms. With predictive maintenance, worn parts can be replaced in advance, reducing annual maintenance costs, improving overall equipment efficiency (OEE), and ensuring long-term stable operation of the system.

Zoomry has established 8 regional service centers in Europe, Africa, and Southeast Asia, equipped with bilingual technical teams and in-stock spare parts warehouses. Through 4G remote guidance and efficient spare parts distribution services, customer needs can be responded to quickly, shortening fault handling time, which is significantly faster than traditional service response speeds, providing timely and reliable support for global customers.

If you have any questions about the cascading solutions of grasshopper conveyors in the field of bulk material handling, please contact us using the following information:

The cascading solution of grasshopper conveyors represents the future direction of the bulk material handling field — efficient, flexible, and sustainable. With three core competencies of technological innovation, global certification, and full-cycle services, Zoomry Heavy Industry is helping global customers reduce operating costs while achieving a win-win situation between environmental benefits and production efficiency. Choosing Zoomry is not only choosing a set of equipment, but also choosing an intelligent conveying partner covering the whole life cycle.

Copyright © 2002-2024 Zoomry Group Company Limited