Time:2025-05-23 17:11:54 Number of Clicks:

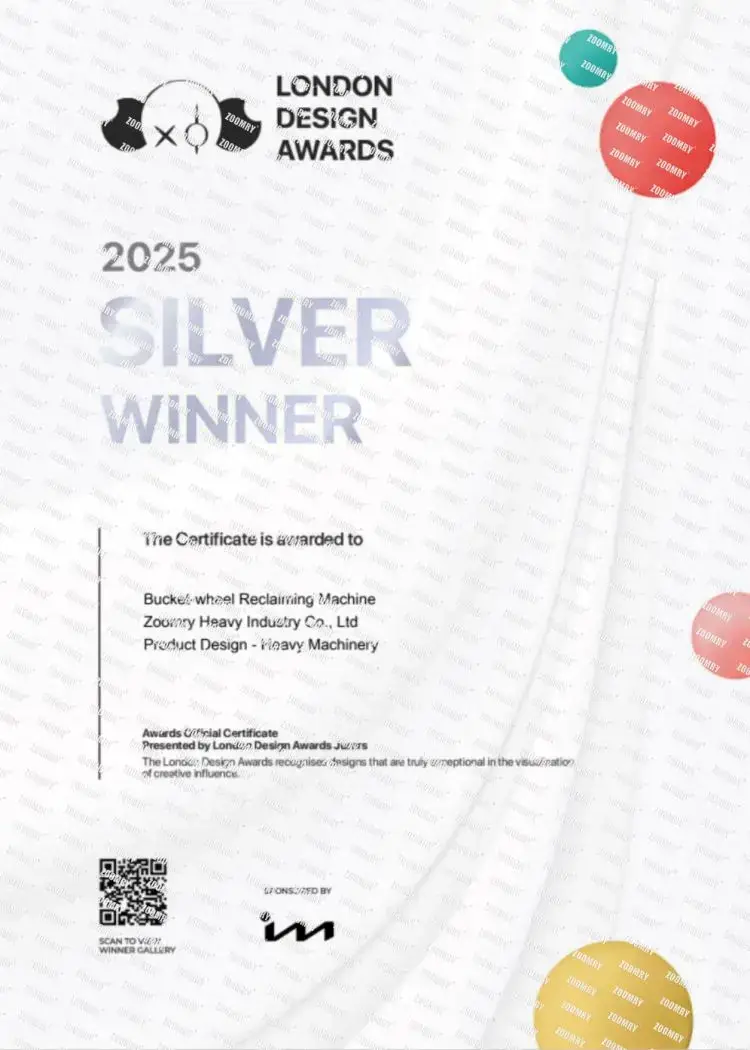

The 2025 London Design Awards, a premier global event in industrial design, has unveiled its winners. Among fierce competition from top international enterprises, Zoomry stood out with its exceptional "Bucket Wheel Stacker-Reclaimer" design, securing the "Silver Award in Heavy Machinery Product Design." This honor not only authoritatively recognizes Zoomry's design capabilities but also marks a new milestone for Chinese high-end equipment manufacturers in global innovation.

Organized by the International Design Association (IDA), the London Design Awards uphold the core philosophy of "Driving Design Innovation, Empowering Industrial Future" and serve as a benchmark in global industrial design. The jury, comprising design masters, engineering experts, and industry leaders from over 30 countries, rigorously evaluated entries based on four dimensions: functionality, innovation, sustainability, and aesthetic value. Zoomry's victory highlights its user-centric, technology-driven design philosophy, resonating deeply with global clients.

Traditional bucket wheel machines face three major challenges: efficiency bottlenecks (single-machine capacity ≤ 5,000 tons/hour), high reliance on manual operation (requiring 3–5 operators), and weak environmental adaptability (limited to fixed-track operation). Zoomry has revolutionized the industry with three breakthroughs:

As a leader in China's bulk material handling sector, Zoomry is committed to "delivering efficient, reliable, and sustainable industrial solutions worldwide," with R&D investment consistently exceeding 8% of annual revenue. The company holds over 200 international patents and boasts certifications including EU CE, Australian AS, and U.S. ANSI:

Cerro Grande Copper Mine, Chile: "Zoomry's stacker-reclaimer operated flawlessly for 18 months at 4,200m altitude, with zero power loss due to hypoxia. Spare part consumption was just 60% of contractual guarantees." — Ricardo Silva, Project Director

Richards Bay Coal Terminal, South Africa: "Traditional equipment required weekly 8-hour lubrication maintenance. Zoomry's auto-greasing module extends intervals to 3 months, saving us over $500K annually." — Thandiwe Nkosi, Operations Manager

BlackRock Mining, Australia: "Three telescopic stackers clocked 20,000+ failure-free hours, far exceeding MTBF commitments. Zoomry’s engineers proactively address risks before we notice them." — James Wilson, Equipment Director

Bintulu Port, Malaysia: "The intelligent anti-clogging design boosted our throughput by 15%. This isn’t just equipment—it’s an operational paradigm shift." — Linda van der Merwe, Project Engineer

Zoomry extends heartfelt gratitude to clients, partners, and design teams worldwide. This London Design Award is both a milestone and a new beginning. We look forward to co-authoring the future of bulk material handling through relentless innovation.

This award honors the trust of every global partner!

Zoomry — Mastering Heavy-Duty with Effortless Precision

Copyright © 2002-2024 Zoomry Group Company Limited