Time:2025-02-06 10:37:32 Number of Clicks:

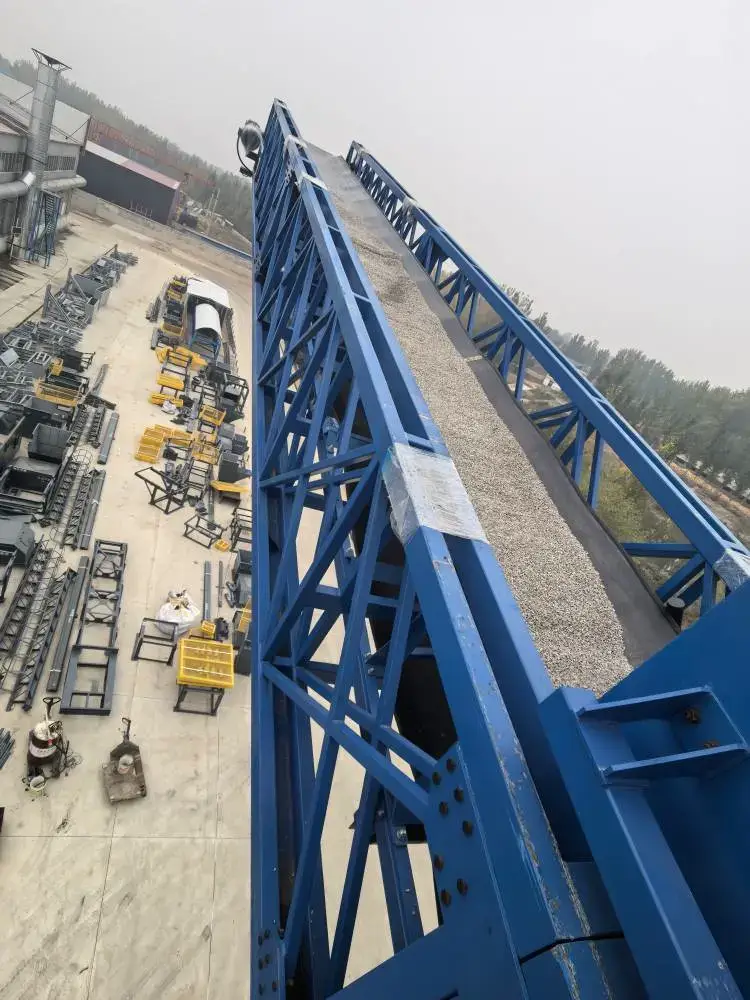

Aggregates, as essential materials for construction and infrastructure projects, have larger particle sizes and higher densities, which often take up space and weight capacity of carriers during loading operations. Furthermore, in bulk transport, the instability of pile formation and the tendency of aggregates to spill can significantly reduce transportation efficiency. To resolve these issues, port loading equipment must possess higher adaptability and performance. In modern port operations, high-efficiency material handling equipment is critical for improving port productivity and reducing cargo turnaround times. Mobile Ship Loader, as an efficient and flexible loading equipment, is gradually becoming the ideal choice for port loading of aggregates and other bulk materials. With its powerful loading capacity and flexible movement modes, the Radial Shiploader not only enhances loading efficiency but also significantly reduces operational costs.

Aggregates are widely used materials in construction and infrastructure projects, typically made from natural minerals or manufactured materials and processed into granular form. Common types of aggregates include:

One of the core features of the Radial Shiploader is its exceptional loading capacity. The equipment is designed to load materials at rates up to 3500 tons per hour, significantly improving operational efficiency, especially for bulk aggregates and other heavy bulk materials. Whether handling sand, gravel, aggregates, or more complex materials like iron ore and coal, the Radial Shiploader provides efficient, seamless loading services, ensuring fast completion of vessel loading tasks.

Compared to traditional loading equipment, the Radial Shiploader offers superior flexibility, capable of adapting to various vessel types, including barges, Handymax bulk carriers, Panamax bulk carriers, and more. Its telescopic arm and adjustable pitching angle design allow the equipment to freely adjust under different working conditions, ensuring operational flexibility and adaptability. Whether handling small vessels or large ships, the Radial Shiploader can provide stable support to help ports efficiently complete loading tasks.

The Radial Shiploader uses several movement modes, including linear, rotating, and radial motion, making it highly maneuverable even in tight spaces within ports. Whether loading around the vessel or transporting materials in complex dock environments, the Radial Shiploader can easily handle various challenges, reducing material spillage or loss during loading and unloading.

For granular materials like aggregates, the precise control system of the Radial Shiploader is crucial. Its intelligent control technology adjusts the loading angle, speed, and direction in real-time, ensuring the stability of aggregates during loading and reducing spillage. Additionally, the equipment is usually equipped with advanced dust suppression systems, such as spraying devices and dust collectors, effectively reducing dust pollution during the loading process and meeting environmental standards, providing a cleaner and more sustainable solution for port operations.

Each port has unique needs, and the customized design of the Radial Shiploader allows it to be tailored to fit different port spaces, vessels, and operational requirements. The installation and deployment time is extremely short, typically requiring only a few hours to assemble and put into use. This not only reduces infrastructure construction costs but also improves port operational efficiency in a short period of time.

Aggregate loading operations are often conducted in harsh environments, and the durability and adaptability of equipment are critical. The Radial Shiploader is built with a sturdy heavy-duty steel structure, capable of withstanding extreme operating conditions to ensure long-term stable operation. Whether in high temperatures, humid conditions, or strong winds, the equipment can perform tasks smoothly, ensuring the normal operation of the port.

Please contact us using the info below if you have any questions about radial shiploader for aggregates

The Radial Shiploader is especially suitable for the loading of aggregates, sand, gravel, and other building materials. With the global growth in the construction industry and infrastructure development, the demand for aggregates continues to rise, requiring ports to rely on efficient and reliable equipment to meet this demand. The Radial Shiploader, with its flexible operational modes and high loading capacity, ensures smooth loading of aggregates and other bulk materials, improving overall port operational efficiency.

In addition to aggregates, the Radial Shiploader is widely used in the mining and energy sectors, particularly for loading bulk materials like iron ore and coal. Ports handling large quantities of minerals and coal require equipment with high loading rates and adaptability. The Radial Shiploader, with its powerful loading capacity and flexible movement modes, can easily handle these challenges and significantly boost operational efficiency.

As a global leader in Radial Shiploader manufacturing, Zoomry Heavy Industry has years of experience in equipment design and production. The company not only offers standardized products but also provides customized services to meet the specific needs of different ports. Whether handling coal, ores, or aggregates, Zoomry's Radial Shiploader offers efficient and reliable solutions.

Copyright © 2002-2024 Zoomry Group Company Limited