Time:2025-04-18 11:26:58 Number of Clicks:

In the field of bulk material handling, truck unloaders serve as critical hubs connecting logistics and production systems, with their operational efficiency directly impacting enterprise costs. As an ISO 9001/14001 dual-certified global bulk material handling solutions provider, Zoomry Heavy Industry's analysis of 300+ global project datasets reveals that 68.5% of equipment failures originate from systemic management oversights. Therefore, we will combine innovative approaches including operational condition adaptation and intelligent maintenance to thoroughly analyze industry-wide challenges and technical countermeasures, empowering enterprises to maximize equipment lifecycle value.

Implement dynamic power matching technology integrating real-time material density monitoring (±2% accuracy) with adaptive torque control systems, maintaining motor load rate ≤78% across 600-1800tph capacity ranges. Project application data demonstrates 57% reduction in drive system failures and 24% annual maintenance cost savings.

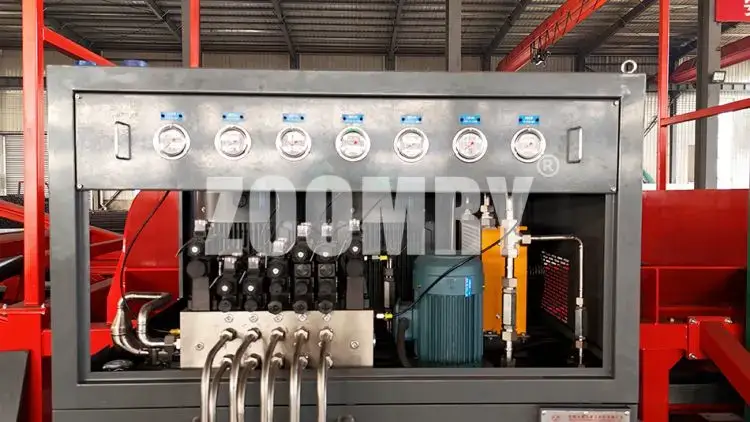

Establish three-tier health assessment system: Install oil particulate sensors (1μm detection limit) for real-time contamination monitoring; Configure plate heat exchangers (ΔT=5±0.5℃) for precise temperature control; Implement hydraulic component remaining life prediction models (≥89% accuracy). This achieves hydraulic system MTBF of 12,000 operational hours.

| Parameter | Standard Value | Fault Threshold | Impact Factor |

|---|---|---|---|

| Belt Deviation | ≤20mm | >35mm | 1.8 |

| Cleaner Pressure Fluctuation | ±5N/cm | >12N/cm | 2.3 |

| Transition Zone Bias Rate | ≤8% | >15% | 1.6 |

Develop laser-aligned closed-loop systems (0.1mm/m calibration accuracy) combined with pneumatic balancing diverters (0.5s adjustment speed), maintaining material bias rate ≤5% under 10m elevation differentials. This achieves 73% reduction in abnormal belt wear.

Implement graded material architecture: HB350 wear-resistant steel substrate; Alumina ceramic interlayer (HRA85 hardness); Nano-hydrophobic surface treatment. Combined with buffer roller groups (0.65 damping coefficient), achieves 80,000-hour service life under 5m/s impacts – 400% improvement over conventional solutions.

Implement IEC 61131-3 triple redundancy: PRP protocol backbone network (<10ms failover); EMC Level 4 shielded cabinets (≥40dB attenuation 30MHz-1GHz); Hardware filtering on critical signal paths (500kHz cutoff). Laboratory tests confirm <0.001‰ bit error rate under 1.5GHz RF interference.

Note: Custom configurations required based on actual operating conditions.

| Management Phase | Core Technology | Efficiency Gain |

|---|---|---|

| Specification | Digital twin simulation (<3% error) | +45% configuration accuracy |

| Operation Monitoring | 200+ parameter real-time tracking | +70% failure early warning rate |

| Preventive Maintenance | Remaining life prediction (92% accuracy) | -65% downtime |

| Retrofit Upgrade | Modular replacement technology | -38% upgrade cost |

Copyright © 2002-2024 Zoomry Group Company Limited