Time:2025-04-16 16:07:36 Number of Clicks:

With global trade volume growing at an annual rate of 4.7% (UNCTAD 2023 data), port operators face critical challenges: traditional fixed shiploading systems struggle to meet modern logistics demands due to a 28% productivity gap during vessel type transitions (Handymax to Capesize); their footprint, 3.7 times larger than mobile bulk material handling equipment, exacerbates spatial constraints and reduces berth turnover efficiency by 19%. Compounding these issues, dust control costs now account for 15% of total operational expenditures under IMO 2020 regulations.

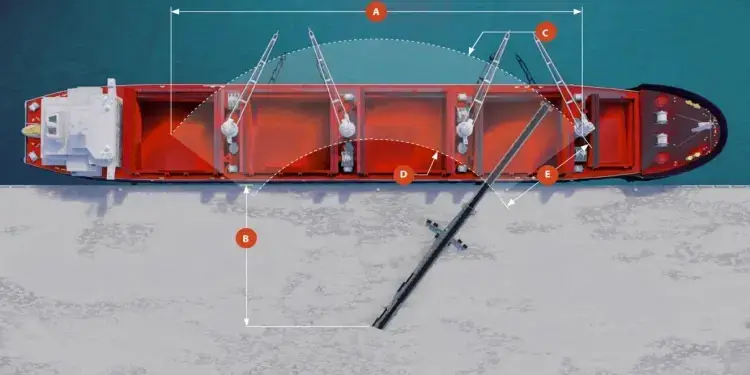

The Panama Canal expansion project exemplifies these challenges, where Neopanamax-class vessels require shiploading systems with dynamic draft adjustment capabilities (±2.1m) and omnidirectional mobility. ZOOMRY Heavy Industry's ZRSL series, through modular hydraulic truss design, achieved a milestone in a Chilean port project by processing three vessel types (5,000-180,000DWT) within a single day, boosting equipment utilization to 79%.

To address mixed vessel operations in modern ports, ZOOMRY recommends replacing traditional linear layouts with a dynamic triangular deployment matrix:

| Functional Dimension | ZRSL-60 | ZRSL-45 | Traditional Equipment |

|---|---|---|---|

| Mobility | Omnidirectional wheeled chassis (0-15km/h) | Crawler steering system (8° slope climbing) | Fixed tracks |

| Vessel Compatibility | Postpanamax-Capesize | Panamax-Handymax | ≤50,000DWT |

| Environmental Performance | CEMA Grade 6 tubular belt + 3-stage dust suppression | Dual-stage dust control | Open conveyor system |

| Energy Consumption | 0.38kWh/ton | 0.42kWh/ton | 0.68-1.2kWh/ton |

For inquiries about modern multi-berth mobile shiploader system deployment, contact us via:

Equipped with HI-Core 7.0 edge controllers, each ZRSL unit integrates 77GHz millimeter-wave radar (±3mm tidal monitoring accuracy), MEMS inertial navigation modules (attitude compensation response <200ms), and multi-source environmental sensors (dust/humidity/wind speed). This layer completes data acquisition-processing-execution cycles within 200ms, providing real-time decision support for boom adjustments and delivering 18x faster emergency response compared to traditional PLC systems.

The dispatch hub, powered by digital twin technology, combines vessel arrival prediction algorithms (92% accuracy) with conveyor speed modulation (0.5-4m/s stepless adjustment). Its multi-machine collision avoidance system maintains ≥2.5m operational safety margins. In Singapore's PSA port trials, this system achieved mixed vessel processing efficiency of 1,850 tons/hour while reducing collision incidents by 17%.

The cloud-based intelligence platform features preventive maintenance models (bearing failure prediction F1-score 0.89), ISO 14064-compliant carbon tracking, and AR-assisted training systems that improve operator skill acquisition by 60%. Leveraging historical operational data, the system predicts idler wear inflection points 35 days in advance, reducing maintenance costs by 42%.

Note: Certain equipment functions and components require customization based on actual operational conditions.

As a Southeast Asian hub port, Jakarta International Port implemented ZOOMRY's ZRSL solutions in its 2022 bulk terminal modernization. The investment structure allocated 58% to mobile shiploaders, 22% to intelligent control systems, and 20% to infrastructure upgrades, maximizing existing assets while adopting advanced technologies.

Post-upgrade metrics show vessel wait times reduced from 54 to 26 hours (51% decrease), driving annual throughput beyond 28 million tons. Shore power utilization rose to 89%, and with Overall Equipment Effectiveness (OEE) reaching 86.7%, annual operating costs per berth decreased by $1.9 million.

Environmentally, the project achieves annual carbon reduction of 24,500 metric tons—equivalent to the carbon sequestration capacity of 53 hectares of tropical rainforest. Closed-loop conveying systems and rainwater recycling cut wastewater production by 78%, saving $450,000 annually in water treatment costs. This initiative has become a benchmark for G20 nation port modernization, attracting study visits from regional peers including Malaysia's Port Klang and Vietnam's Haiphong Port.

As a TÜV Rheinland-certified bulk material handling expert, ZOOMRY Heavy Industry delivers complete value-chain services from design to smart operations. Access our Technical Whitepaper Library for cutting-edge port automation solutions.

Copyright © 2002-2024 Zoomry Group Company Limited