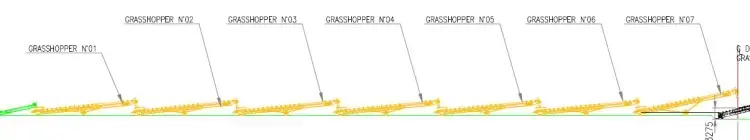

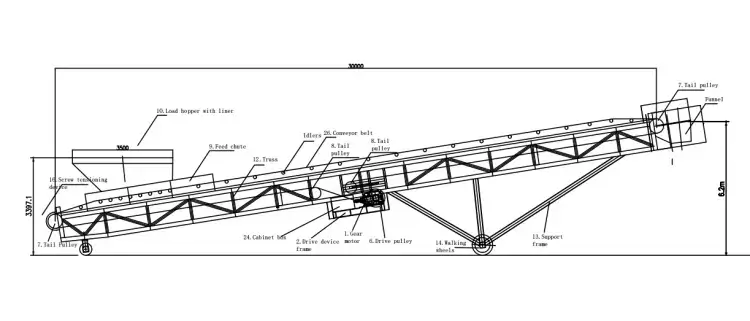

Transportador de Saltamontes, also known as transfer conveyors, are a specialized type of conveyor primarily used for efficiently transporting bulk materials over long distances. Their flexible design allows them to operate in various terrains and environments, making them particularly suitable for uneven or steep landscapes. By eliminating reliance on traditional loaders, trucks, fuel, and labor, Transportador de Saltamontes enable producers to transfer materials more efficiently from one location to another. This flexibility in site layout optimizes stockpiling and storage space, reduces labor costs and production time, and finds widespread application in quarries, mining, logistics, ports, inland terminals, power stations, and other industries. Using Transportador de Saltamontes is often the most cost-effective and environmentally friendly method of material handling.

Transportador de Saltamontes Specifications

| Tipo | Capacidad | Longitud | Potencia de la cinta transportadora | Potencia del motor de desplazamiento | Inclinación máxima | Altura de la pila | Velocidad de la cinta |

|---|

| t/h | m | kw | kw | ° | m | m/s |

|

| ZR65D | 200 | 20/25 | 18.5 | 11 | 18 | 6.5/8.0 | 2 |

| ZR80D | 300 | 20/25 | 22 | 11 | 18 | 6.5/8.0 | 2 |

| ZR100D | 400 | 20/25 | 30 | 15 | 18 | 6.5/8.0 | 2.5 |

| ZR120D | 550 | 20/25 | 37 | 15 | 18 | 6.5/8.0 | 2.5 |

Applications of Transportador de Saltamontes

Mining Industry: Transportador de Saltamontes are widely used for transporting ore, efficiently working in uneven terrain to directly transfer materials from extraction sites to processing plants.

Construction and Civil Engineering: At construction sites, Transportador de Saltamontes can efficiently transport concrete, sand, and gravel, reducing manual handling and enhancing construction efficiency.

Logistics and Ports: In ports and inland terminals, Transportador de Saltamontes facilitate the efficient transfer of materials from truck unloaders and hopper feeders to ship loaders.

Recycling and Waste Management: In the recycling industry, Transportador de Saltamontes efficiently transfer recyclable materials to processing facilities, minimizing material loss.

Advantages of Transportador de Saltamontes

Adjustable Discharge Height: The discharge height can be adjusted to meet various operational requirements, accommodating different equipment and working environments.

Reduced Loader Movement: By optimizing material transfer processes, the frequency of loader movements is significantly decreased, leading to lower operational costs.

Flexible Layout: The design allows for multi-directional stacking, enabling efficient operations in limited spaces.

Easy Storage: The modular design allows for easy storage when not in use, saving space.

Customizable Options: Conveyors can be tailored to meet specific customer needs in terms of specifications and functionalities.

Transfer conveyor connections

From crusher to stacker

Port yard stacking

Port yard recycling

Railcar and barge loading

Stockyard recycling

Why Choose Zoomry Transportador de Saltamontes

Flexible Operation: Transportador de Saltamontes can quickly adjust based on transfer length and operational requirements, adapting to various work environments.

Durable Design: The truss structure of the equipment is engineered for long-term use in harsh mining conditions.

Automated Control: The internal electrical system can automatically shut down the conveyor in case of production interruptions, ensuring safety and efficiency.

Cost Reduction and Efficiency Improvement: By reducing labor and fuel consumption, Transportador de Saltamontes significantly lower overall operating costs and enhance productivity.

Features of Transportador de Saltamontes

Transportador de Saltamontes typically consist of field-bolted prefabricated truss sections, ensuring stability and durability across different environments. One end is elevated by struts from an axle equipped with tires, facilitating flexible movement on slopes and uneven terrain. Additionally, the equipment is usually moved by large forklifts or front-end loaders, enhancing efficiency in material transfer at construction sites and mining operations.